AGV trolley for mounting screws and working method thereof

A technology for installing screws and screws, applied in manufacturing tools, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve the problems of improper operation, damaged parts, low efficiency, error-prone, etc., and achieve reliable transmission , Guarantee accuracy, improve the effect of installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

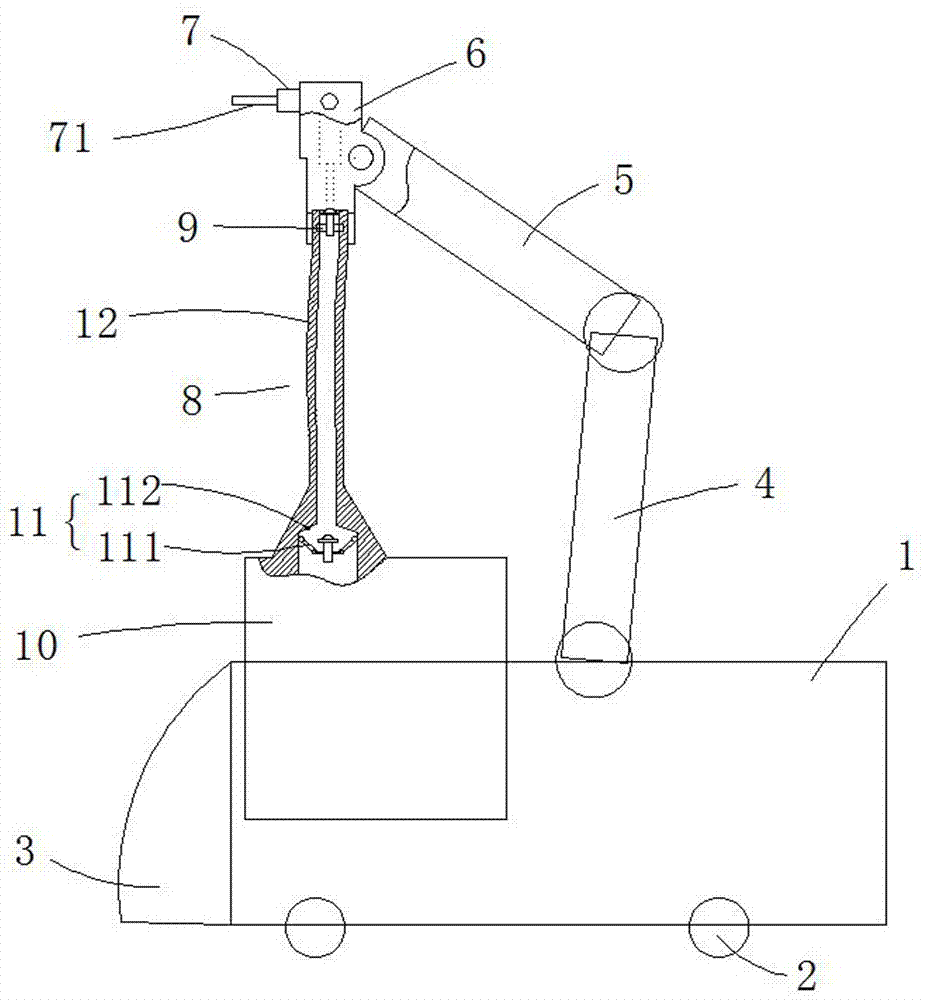

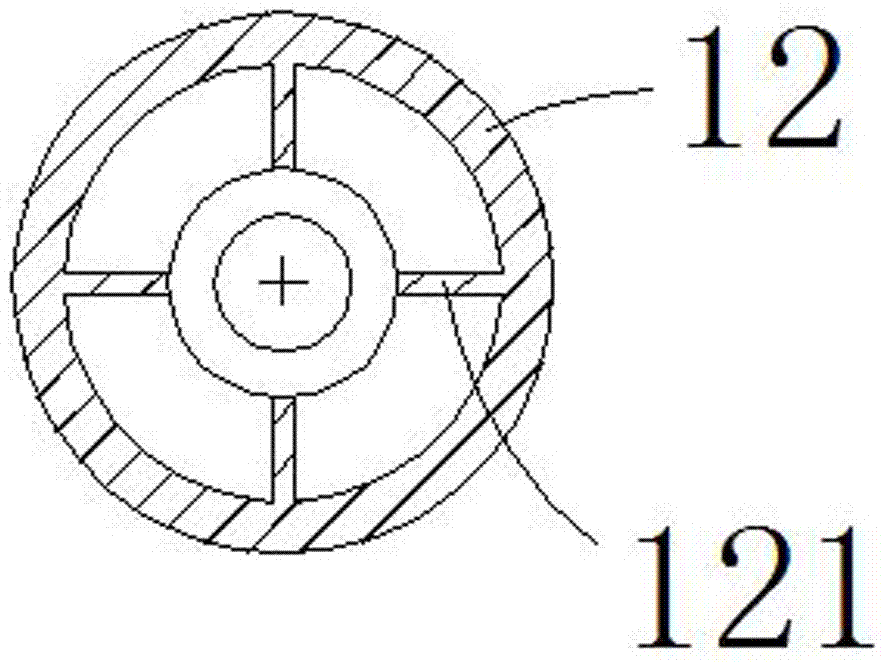

[0026] A kind of AGV trolley that installs screw of the present invention is used, as figure 1 and figure 2 As shown, it includes a control module, a drive system, a vehicle body 1, a roller 2 arranged under the vehicle body 1, an automatic guidance system 3 arranged in the vehicle body 1, and a screw installation system arranged above the vehicle body 1; the screw installation system It includes a first mechanical arm 4 connected to the vehicle body 1, a second mechanical arm 5 connected to the first mechanical arm 4, and a screwdriver holder 6 connected to the second mechanical arm 5; an automatic screwdriver device is provided at one end of the screwdriver holder 6 7. The other end is connected with a screw transmission device 8; the automatic screwdriver device 7 is hinged with the screwdriver frame 6, and is connected with a reversing drive device; the end of the screw transmission device 8 close to the screwdriver frame 6 is provided with an air suction device 9. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com