A feeding system for small spare parts and its working method

A feeding system and spare parts technology, applied in the field of industrial robots, can solve problems such as damaged parts, low efficiency, misinstallation, etc., achieve reliable delivery, ensure accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

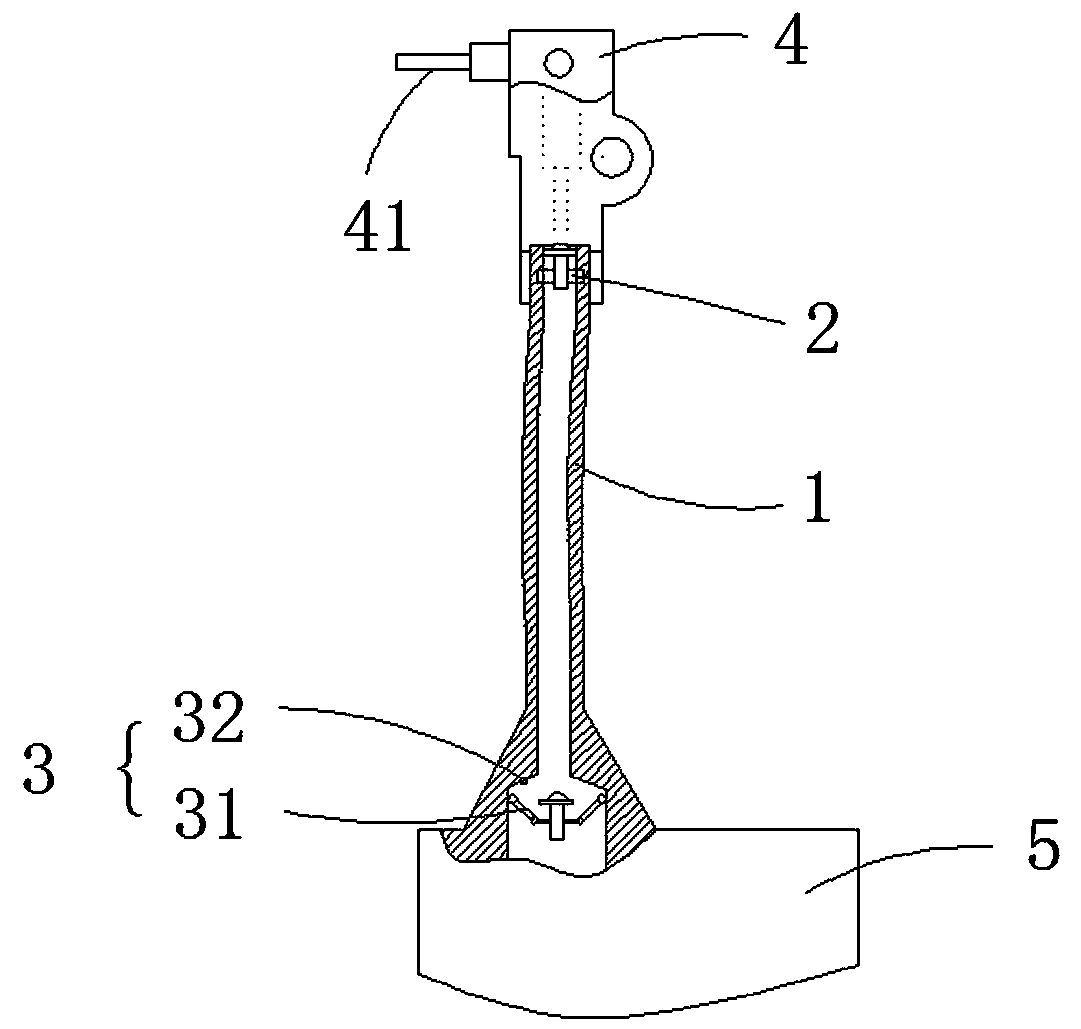

[0023] The feeding system of a kind of small spare parts of the present invention, as figure 1 with figure 2 As shown, it includes a control module, a drive system, a transmission channel 1, and an air suction suction device 2 and a retrieving device 3 arranged in the transmission channel 1; the reclaiming device 3 includes a pair of jaws 31 and a detection device 32 . The suction suction device 2 is arranged at one end of the conveying channel 1 close to the installation system 4 . The material retrieving device 3 is arranged at one end of the conveying channel 1 close to the material storage system 5 .

[0024] The delivery channel 1 in this embodiment is made of soft material.

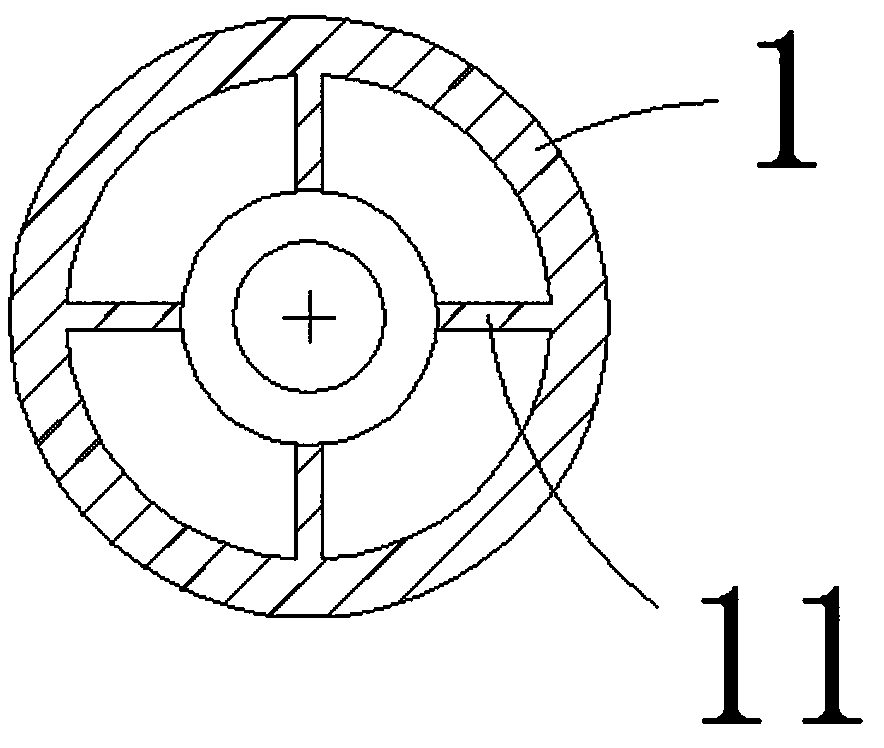

[0025] In this embodiment, a set of guide ribs 11 is provided inside the conveying channel 1 , wherein the distance between the opposite guide ribs 11 is adapted to the diameter of the pre-transported parts.

[0026] In this embodiment, the pair of clamping jaws 31 are rotatably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com