Steam turbine set emergency governor test device

A technology of steam turbine unit and test device, which is applied in the direction of measurement device, machine/structural component test, engine test, etc., can solve the problems of high fuel consumption and time consumption, improve work efficiency, facilitate observation, and reduce equipment The effect of the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

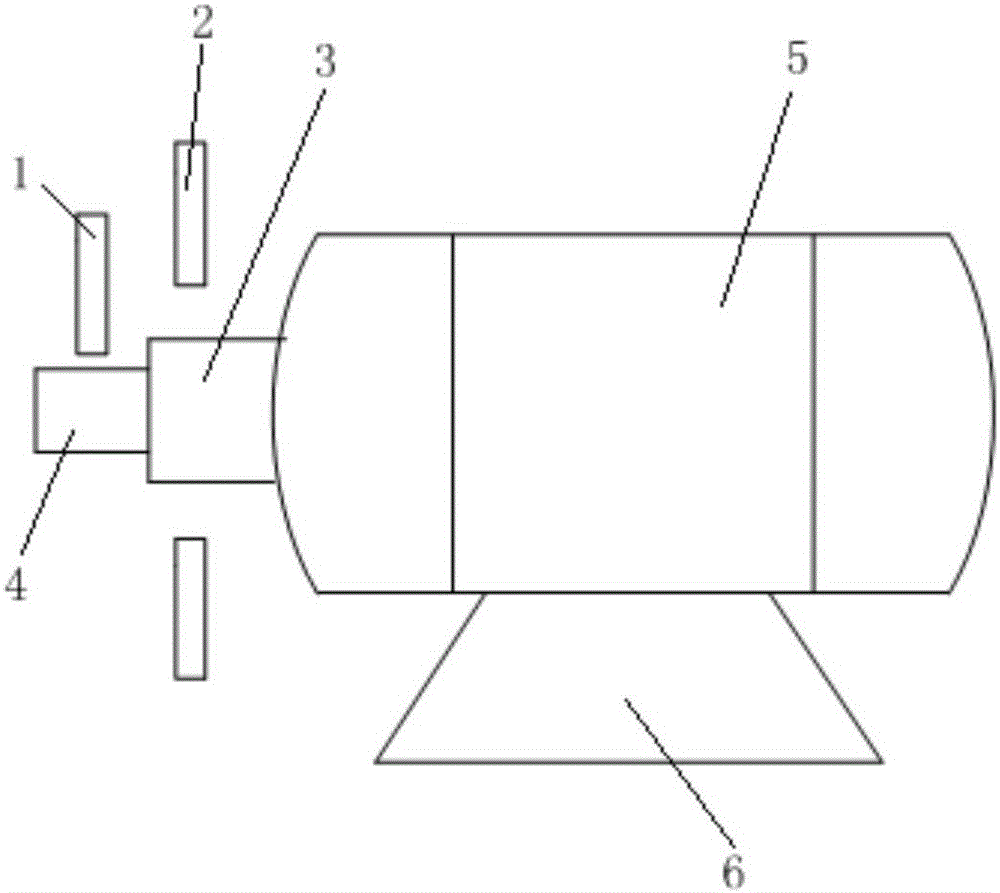

[0033] Such as picture 1 As shown, the test device for the emergency breaker of the steam turbine unit in this embodiment can ensure the accuracy of the operating speed of the steam turbine and protect the safety of the main engine equipment of the steam turbine, including:

[0034] Crisis Interrupter 4;

[0035] The power output end is connected with the rotor of the crisis breaker, and drives the frequency conversion motor 5 of the crisis breaker to rotate, and the frequency conversion motor and the crisis breaker are connected through the fixing device 3;

[0036] A rotational speed measuring device 2 for recording the rotational speed of the variable frequency motor in real time;

[0037] A flyweight motion sensor 1 for monitoring the flying weight of the crisis breaker, the flyweight motion sensor is a crisis breaker throttle.

[0038] And, the controller connected to the variable frequency motor, the rotational speed measuring device, and the flyweight action senso...

Embodiment 2

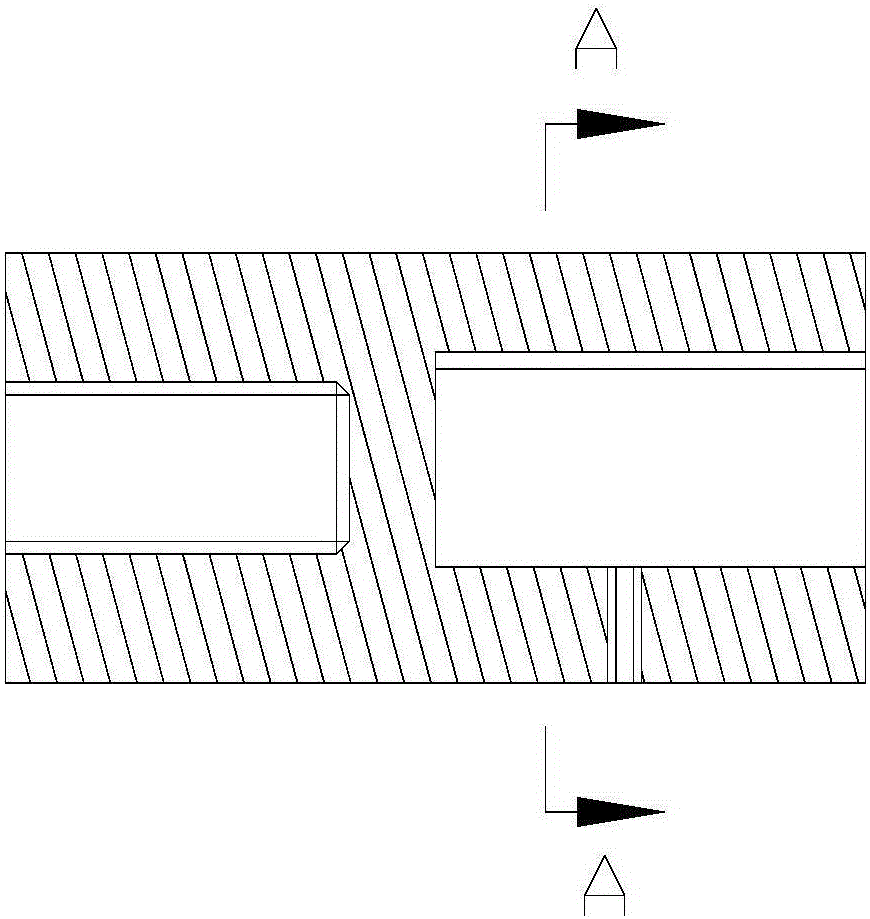

[0046] as shown in the picture 2 to 4 As shown, the test device for the emergency breaker of the steam turbine unit in this embodiment, on the basis of Example 1, the fixing device includes a breaker connection part and a motor connection part, and the breaker connection part is a threaded sleeve structure. The threaded sleeve is provided with an internal thread that matches the external thread on the breaker shaft. The motor connection part includes a key sleeve structure, and the key sleeve is provided with a keyway structure. The power output of the motor The shaft is connected to the connecting part of the motor through bolts.

[0047] In this embodiment, the fixing device has reasonable structure, convenient installation and disassembly, and high safety performance.

Embodiment 3

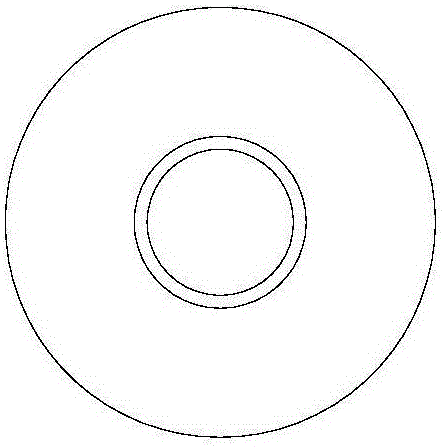

[0049] as shown in the picture5 to 7 As shown, the test device for the emergency breaker of the steam turbine unit in this embodiment, on the basis of Embodiment 2, the described emergency breaker includes a connecting body ( in the picture not marked) and a flyweight 11, the flyweight 11 is formed with a mounting cavity 14, a bushing 16 is installed in the mounting cavity 14, a spring 17 is connected to the bushing 16, and the flyweight 11 One end is provided with sliding sleeve 5 and nut ( in the picture not marked), an adjustment sleeve 18 is provided between the inner wall of the flyweight 1 and the bushing 16, a stopper 12 is provided at the other end of the flyweight 1 opposite to the sliding sleeve 5, and a tight stopper 12 is provided on the stopper 12 Firmware 10, the flyweight 11 and the block 12 are detachably fixedly connected by fasteners 10, the block 12 is provided with at least four threaded holes, and the flyweight 1 is provided with threaded holes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com