Mixed core reactor structure

A kind of reactor, mixed iron technology, applied in the direction of transformer/inductor core, circuit, electrical components, etc., can solve the problems of amplifying the imbalance between three phases, the circuit characteristics are deteriorating, the three-phase characteristics are unbalanced, etc., to reduce the three-phase characteristics. Phase unbalance, ensuring excellent characteristics, and the effect of equal magnetic circuit lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

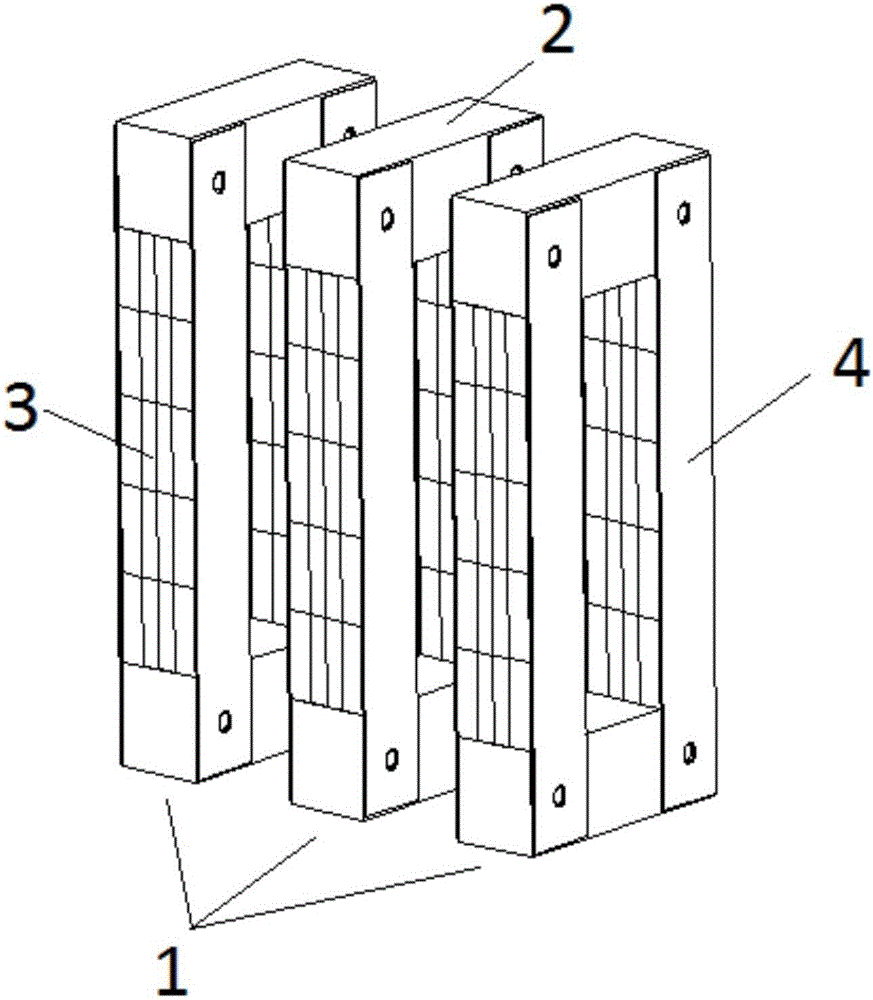

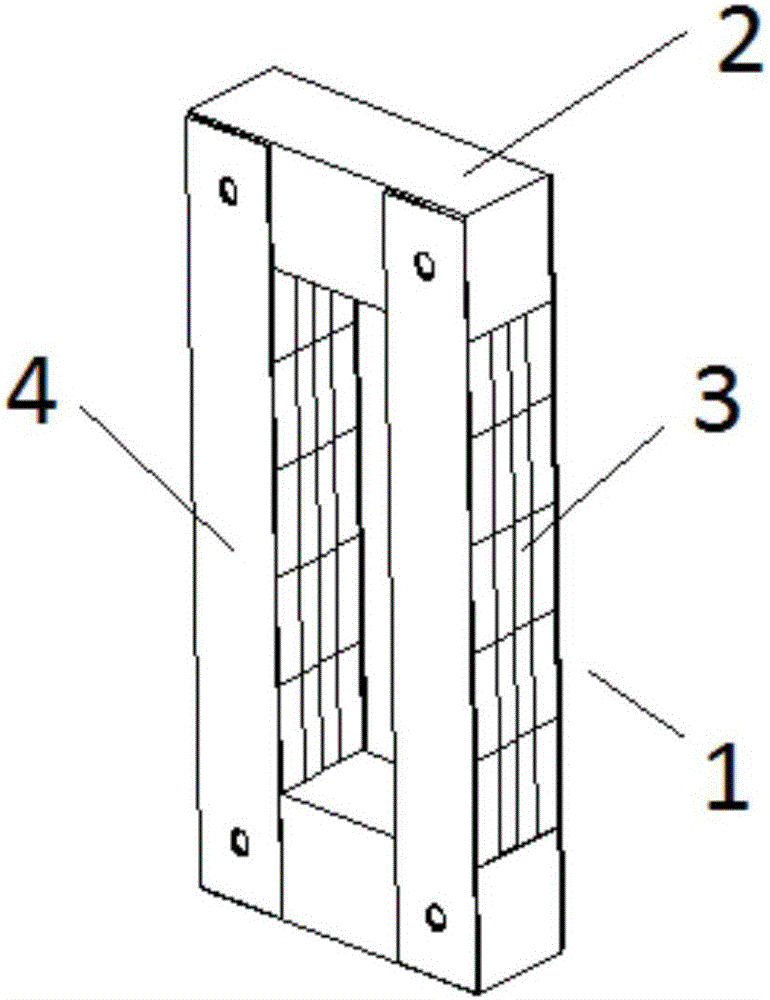

[0010] Such as figure 1 and figure 2 As shown, a hybrid core reactor structure, which is arranged side by side by three identical single-phase reactors 1 equidistant; the single-phase reactor 1 is a hybrid core structure, which includes a core column 2; the core column 2 Iron yokes 3 are arranged at the upper and lower ends; clamping plates 4 are arranged at the front and rear sides of the core column 2 .

[0011] A hybrid core reactor structure in this embodiment, the three-phase reactor is decomposed into three single-phase reactors, each single-phase reactor adopts a hybrid core structure, and a certain distance is kept between the cores to avoid the generation of a magnetic field between the three phases Interference; that is, it ensures the excellent characteristics of the hybrid core reactor, and also makes the length of the magnetic circuit between the three phases equal, which greatly reduces the three-phase unbalance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com