Double-surface OLED display and manufacturing method thereof

A display, double-sided technology, used in semiconductor/solid-state device manufacturing, final product manufacturing, sustainable manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following description, for purposes of illustration rather than limitation, specific details, such as specific system architectures, interfaces, and techniques, are set forth in order to provide a thorough understanding of the present invention.

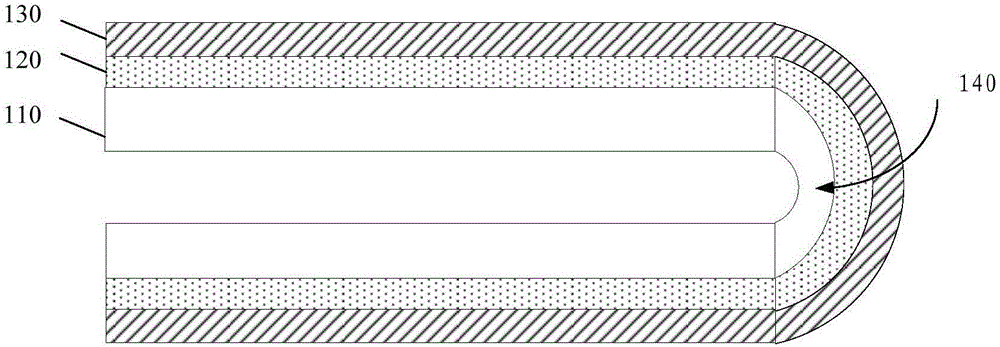

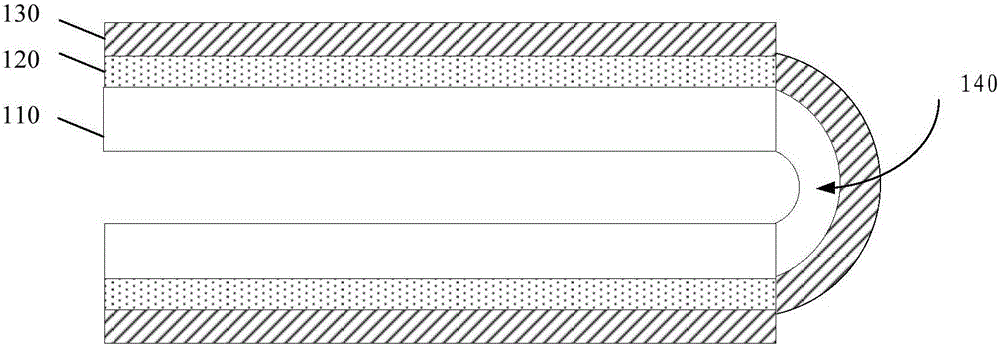

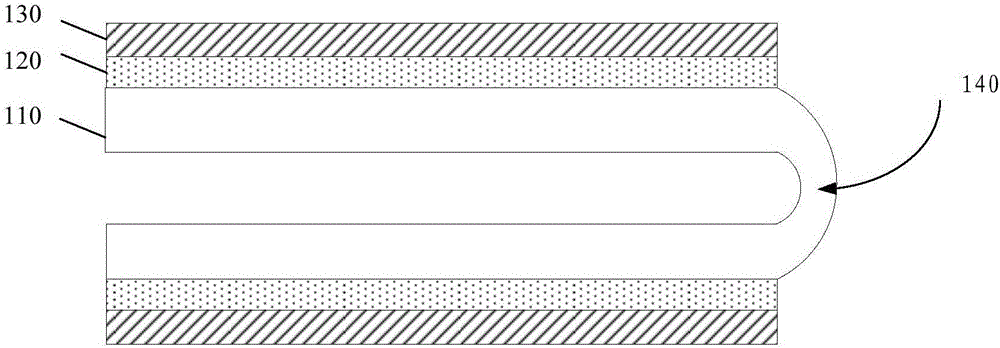

[0022] The present invention provides a double-sided OLED display and its manufacturing method. In each embodiment of the present invention, although the OLED display is simplified into three structures: The display needs each component. Although the present invention has only briefly described the partial structure and components of the OLED display for the convenience of the invention, it is not limited thereto: for example, the substrate can be thin glass, metal, plastics, etc., and the substrate can be a fully flexible substrate (organic substances such as PI) , and a mixed structure composed of organic and inorganic substances); for example, the light-emitting layer includes TFT control switches, light-emitting mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com