Single loudspeaker and production method of single loudspeaker

A loudspeaker and single-unit technology, applied in the field of loudspeakers, can solve the problems of magnetic circuit system offset and unreliability, achieve high-quality sound effects, good reliability, and solve the effect of magnetic circuit system offset and unreliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

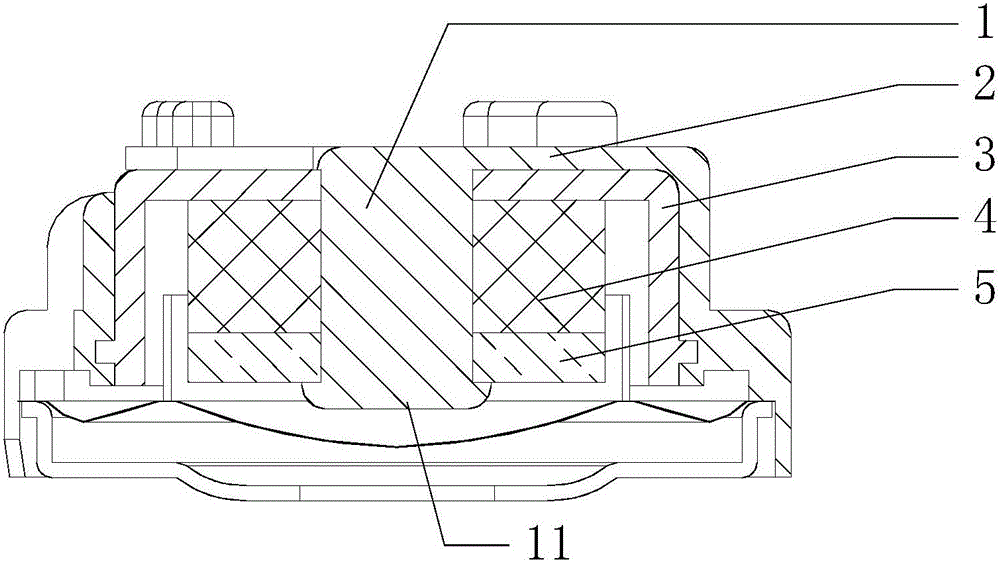

[0023] figure 1 A sectional view of a loudspeaker unit provided by an embodiment of the present invention.

[0024] Such as figure 1 As shown, the speaker unit includes a magnetic cover 3, a magnet 4 and a washer 5 arranged in sequence, and the centers of the magnetic cover 3, magnet 4 and washer 5 are respectively provided with openings of the same shape and size; the speaker unit is provided with a The fixed column 1, the shape of the fixed column 1 matches the opening; the magnetic cover 3, the magnet 4 and the washer 5 are set on the fixed column 1, and are concentrically fixed together by the fixed column 1.

[0025] Holes are made in the center of the magnetic cover 3, magnet 4, and washer 5 of the speaker unit, and the fixing column 1 adapted to the shape of the opening is used to penetrate the three together. On the premise of ensuring the concentricity of the three, the All three are firmly held together. The loudspeaker unit with this structural design can ensure ...

Embodiment 2

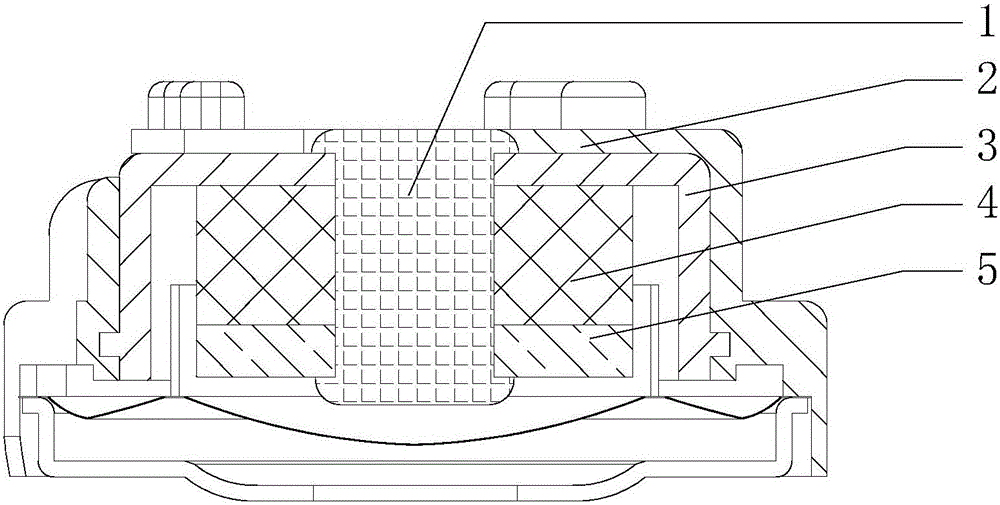

[0032] figure 2 A sectional view of a loudspeaker unit provided by another embodiment of the present invention, different from Embodiment 1, the fixing column 1 is a metal rivet, and the magnetic cover 3, the magnet 4 and the washer 5 are concentrically fixed together by the riveting process .

[0033] The invention also discloses a method for making a loudspeaker unit. The loudspeaker unit includes a magnetic cover, a magnet and a washer arranged in sequence. The opening of the loudspeaker unit is provided with a fixed column whose shape matches the opening; the magnetic cover, magnet and washer are placed on the fixed column, and the three are concentrically fixed together through the fixed column.

[0034] Holes are made in the center of the magnetic cover, magnet and washer of the loudspeaker unit, and the fixing columns that match the shape of the opening are used to connect the three together. On the premise of ensuring the concentricity of the three, the three are fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com