Imprinting device

A technology for placing and transferring bodies, applied in the directions of optics, instruments, opto-mechanical equipment, etc., can solve the problems of bending of the mold 30, deterioration of the transfer of micro-patterns, etc., and achieve the effect of uniform transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

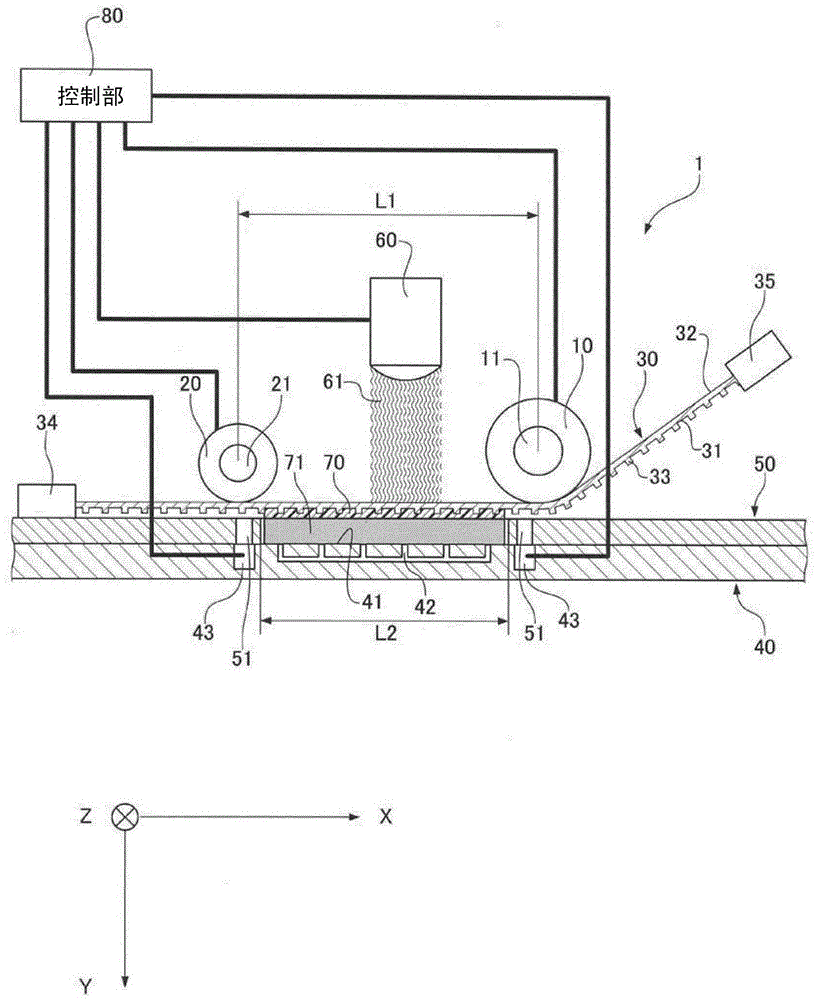

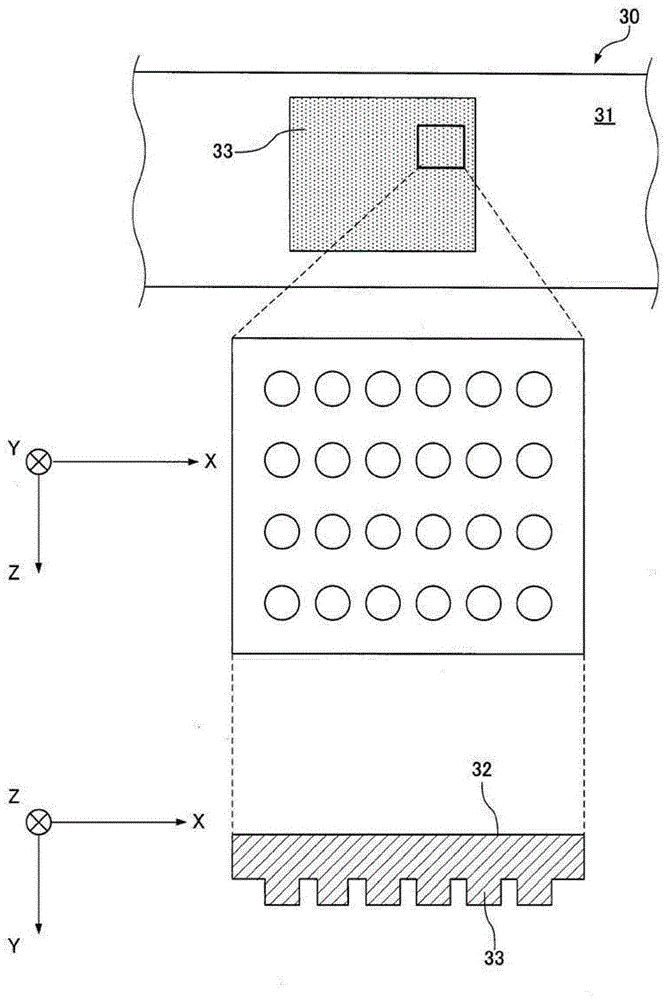

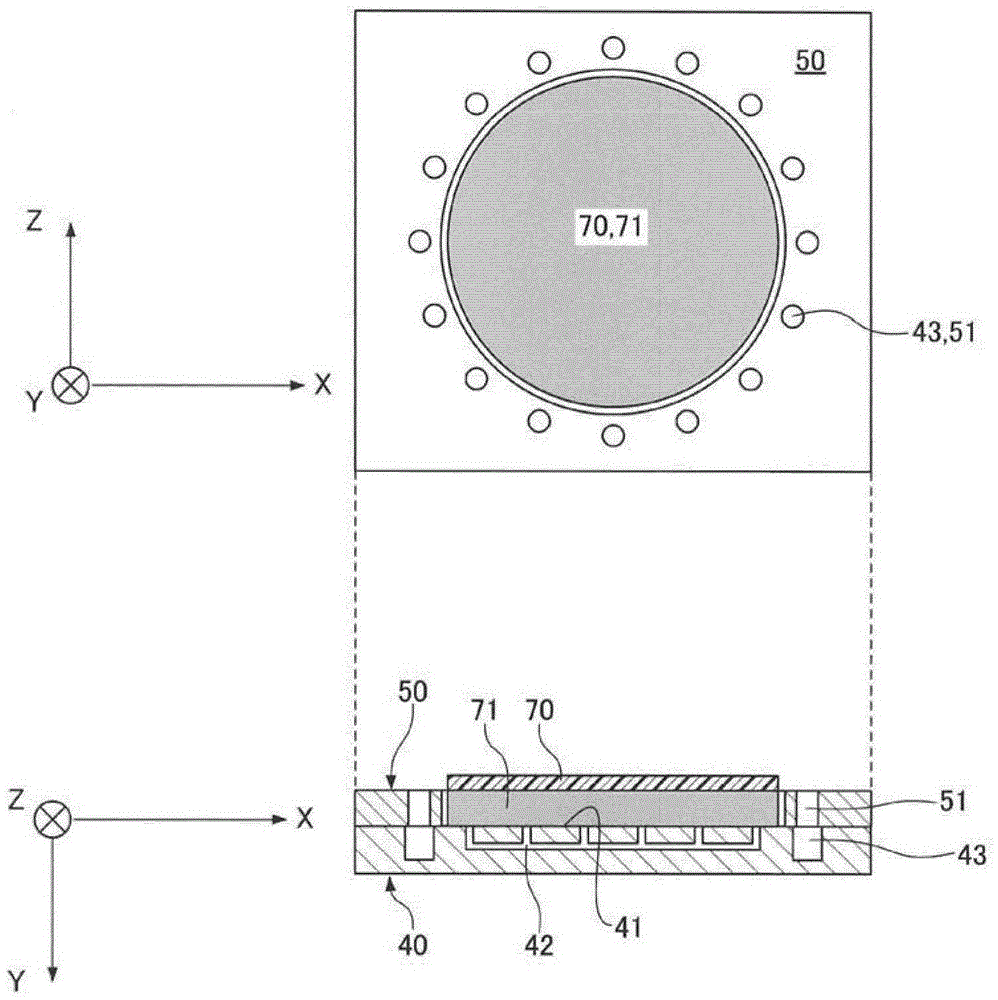

[0043] Hereinafter, the configuration of the imprint apparatus according to the embodiment of the present invention will be described with reference to the drawings. Such as figure 1 As shown, the imprint apparatus 1 according to the embodiment of the present invention includes a pressing roller 10 , a holding roller 20 , a mold 30 , a stage 40 , a flat plate 50 , a UV irradiator 60 , and a control unit 80 . The imprint apparatus 1 according to the embodiment of the present invention employs a roll-type UV imprint method.

[0044] The pressing roller 10 has a cylindrical shape, has a shaft 11 at its center, and is rotatable around the shaft 11 . In addition, the pressing roller 10 is movable on a plane perpendicular to the direction of the shaft 11 (axial direction Z). In other words, the pressing roller 10 is movable in a direction toward the table 40 (pressing direction Y) and a direction perpendicular to the axial direction Z and the pressing direction Y (feeding directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com