A high-speed printing machine for energy saving and emission reduction

A technology for energy saving and emission reduction, printing machine, applied in printing machine, printing, general parts of printing machinery, etc., can solve the problems of bulky heating package, low return air rate, large wind resistance, etc. The effect of saving energy and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

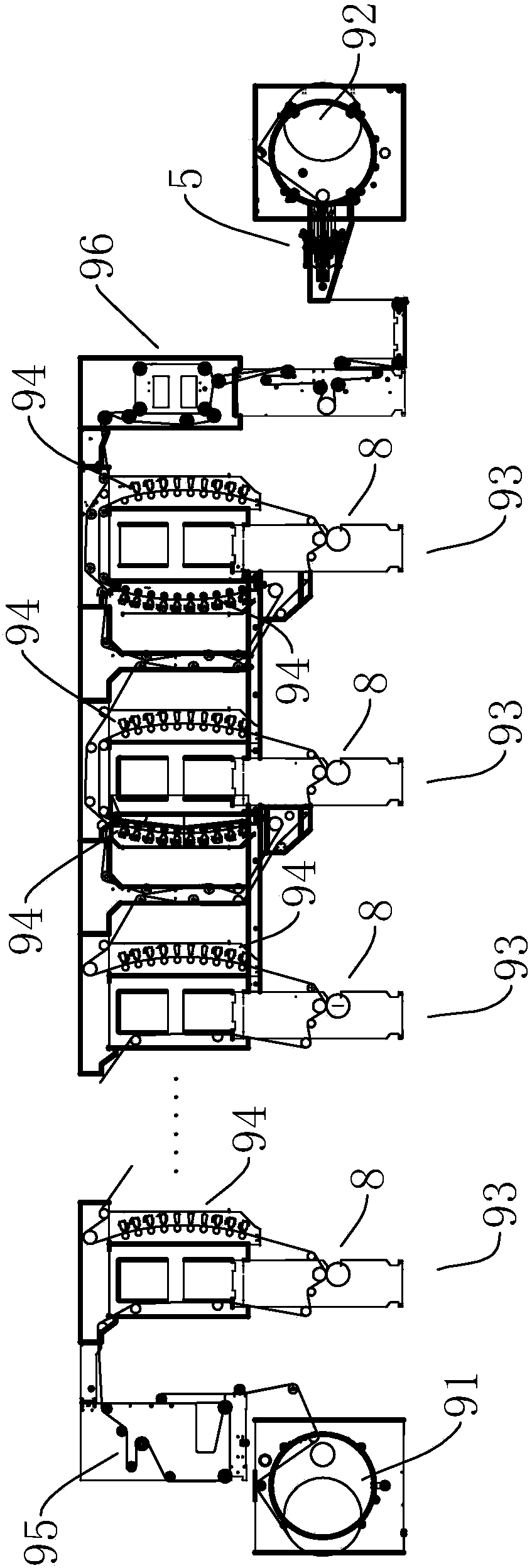

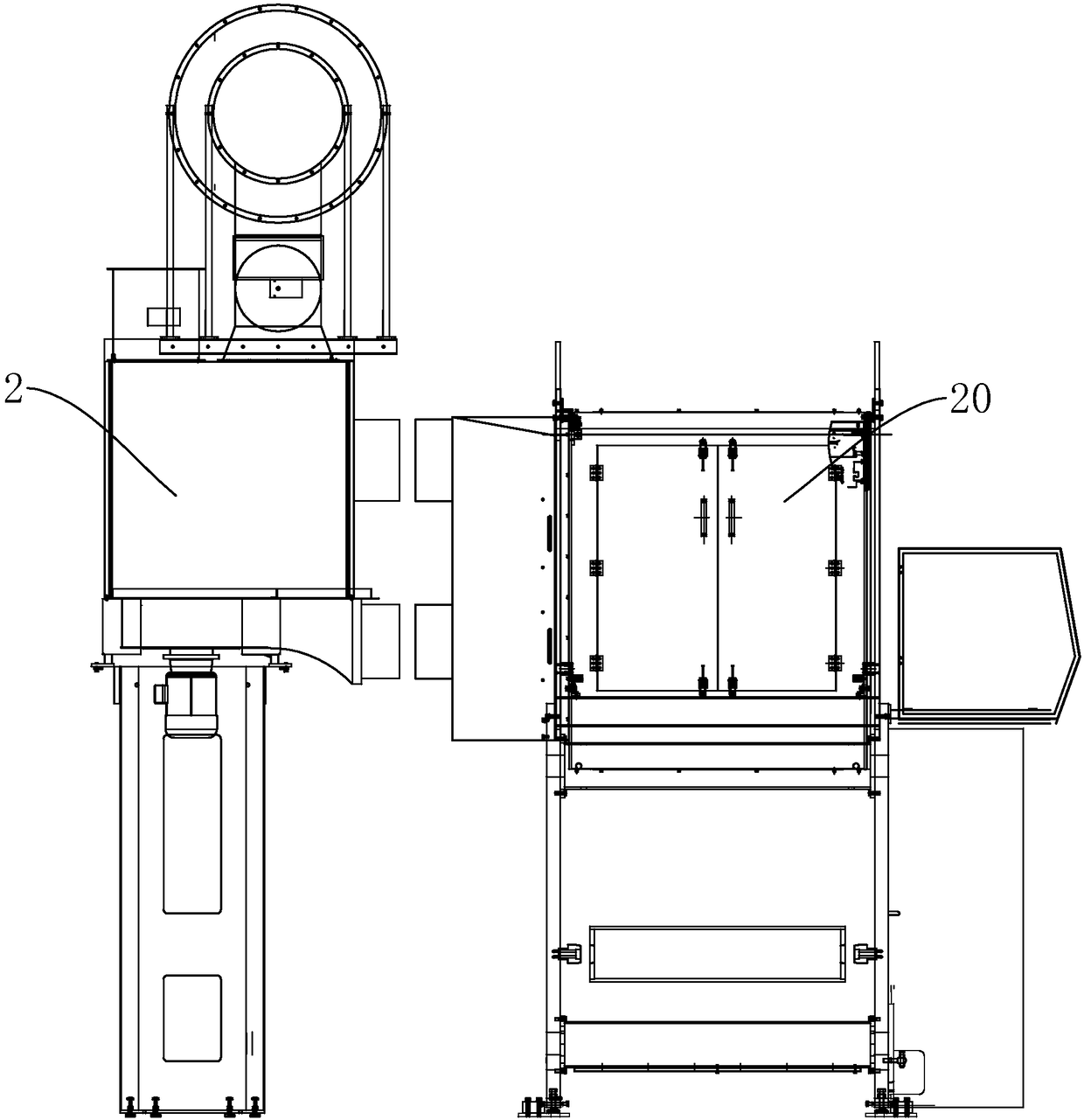

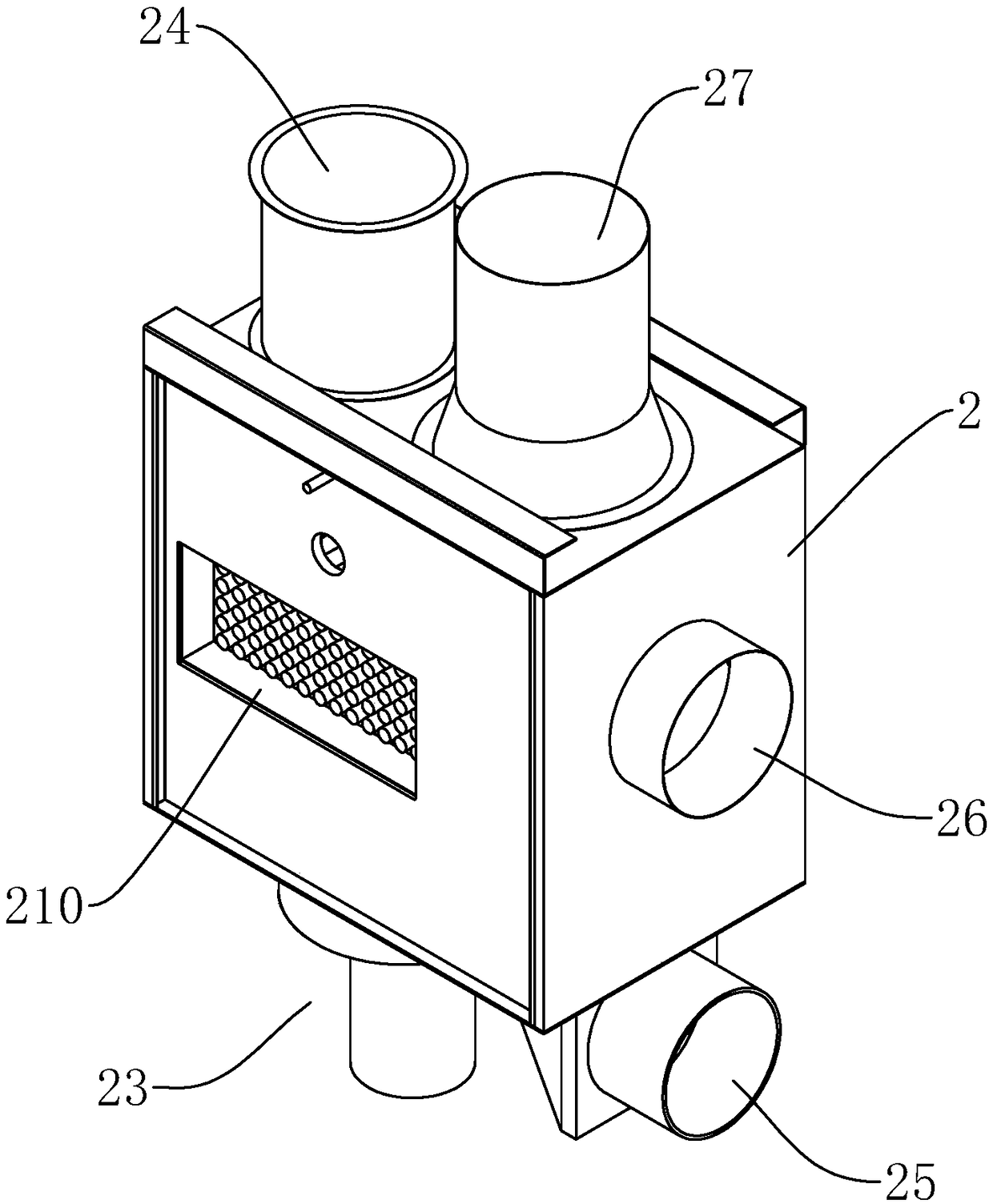

[0047] refer to Figure 1 to Figure 26 , Figure 1 to Figure 26 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, an energy-saving and emission-reducing high-speed printing machine includes an unwinding unit 91, a winding unit 92 and several The printing unit 93 of the printing unit 93 is equipped with a heating unit 94 on the discharge side or both sides of the printing unit 93; A heating system and blowing equipment are arranged inside, and an air duct control device capable of circulating the exhaust gas of the oven 20 to the blowing equipment or being discharged outside is arranged in the bellows box 2; the unwinding unit 91 includes an unwinding rotary The frame and the two groups are respectively provided with the chuck mechanism on both sides of the unwinding slewing frame, and the chuck mechanism can clamp and fix the air shaft; the printing unit 93 includes an ink filling mechanism and an embossing mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com