Double-toothed roller crusher and working method thereof

A crusher and double-toothed roller technology, which is applied in grain processing and other directions, can solve the problems of affecting crushing efficiency, poor cleaning ability of toothed rollers, and ineffective crushing of materials, so as to improve cleaning efficiency and good self-cleaning ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

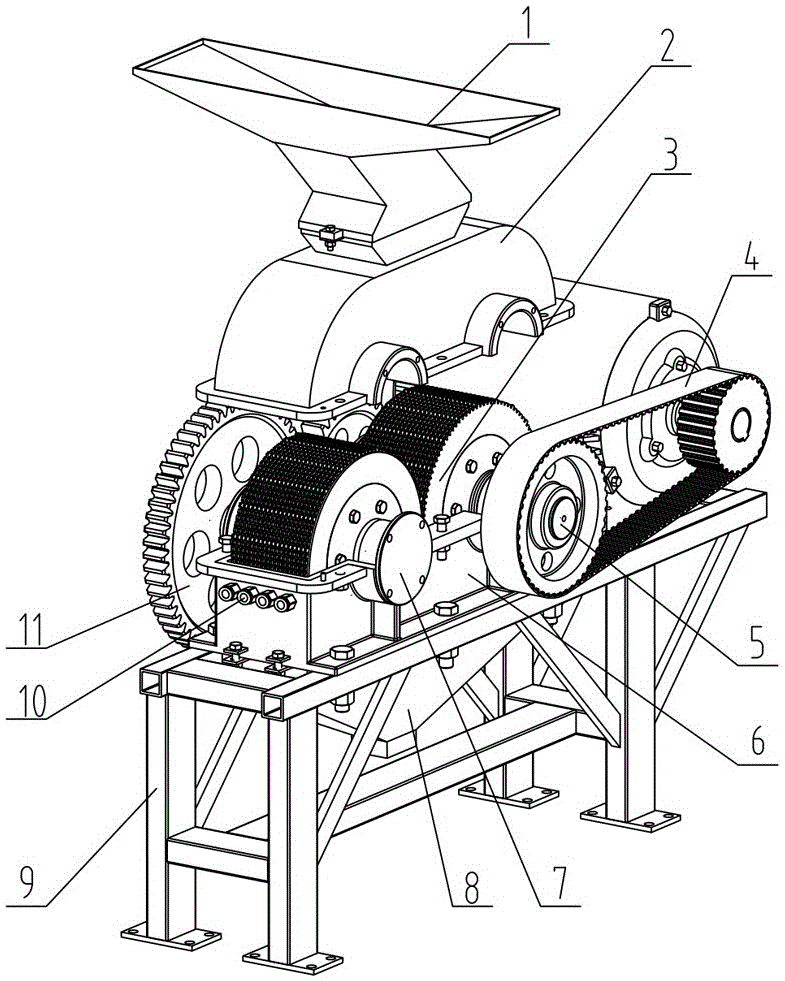

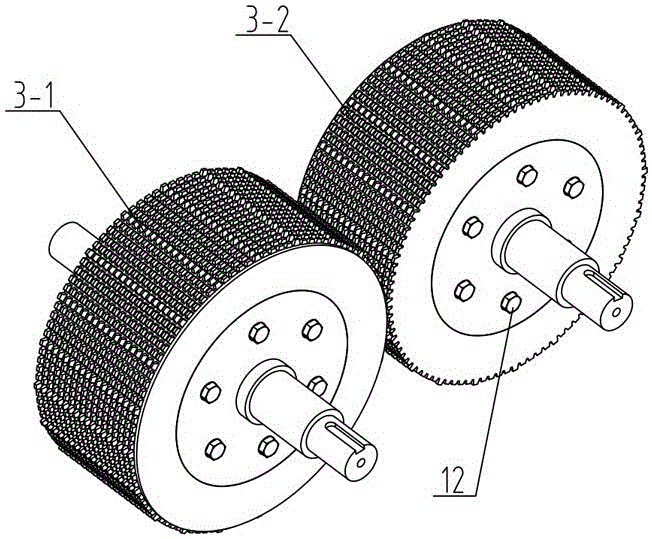

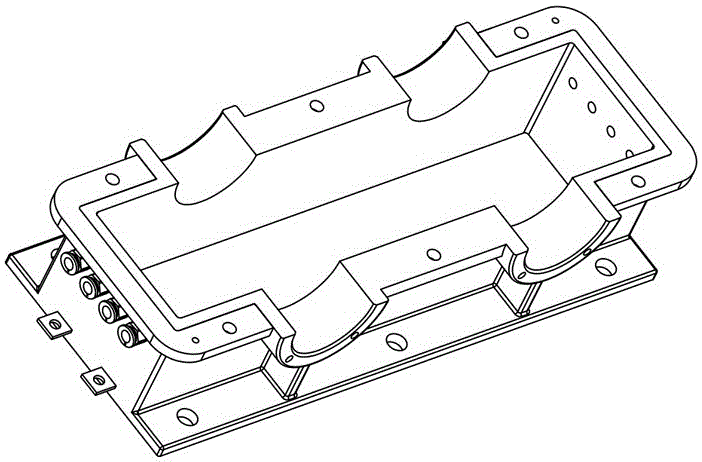

[0023] The overall structure of the present invention is as figure 1 As shown, it includes a feed hopper 1, an upper box body 2, a toothed roller 3, a power unit 4, a main shaft 5, a lower box body 6, an end cover 7, a discharge hopper 8, a base 9, an air inlet pipe 10, and a transmission device 11; The hopper 1 is set at the entrance of the upper box body 2. The two are connected and fixed by bolt holes on the side. The lower box body 6 is located directly below the upper box body 2, and the upper box body 2 and the lower box body 6 are opened through the front and rear sides of the box body The connecting hole is bolted. The gear roller 3 is divided into a left gear roller 3-1 and a right gear roller 3-2. The right gear roller 3-2 is connected to the main shaft 5. One side of the main shaft 5 is equipped with a power unit 4, and the other side It is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com