A main clamping head of a vertical broaching machine

A vertical broaching machine and tool clamping technology, which is applied in the direction of manufacturing tools, chucks, metal processing machinery parts, etc., can solve problems such as unsmooth clamping tools, accumulation of iron filings, scratches on jaws, etc., to avoid clamping failure Stable, reduce the accumulation of iron filings, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

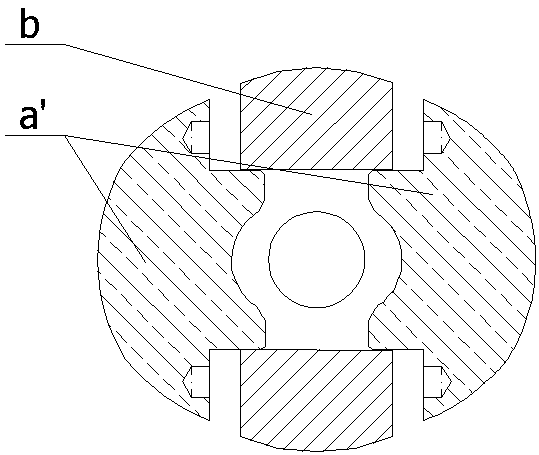

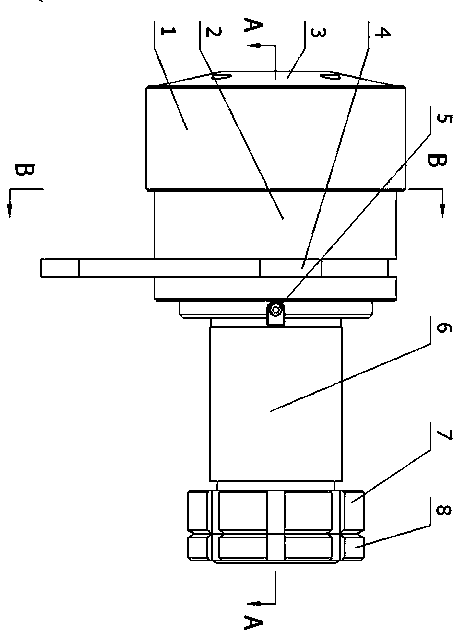

[0025] refer to Figure 3~6 , a main clamping head of a vertical broaching machine, comprising a top cap 3, a sleeve 1, a sliding sleeve 2, a claw 9, a clamping body 6 and a shift fork 4; the top cap 3 is fixed on one side of the clamping body 6 One end of the claw 9 is connected with the sliding sleeve 2; one end of the sliding sleeve 2 is connected with the top cap 3 through the sleeve 1, and the other end is connected with the shift fork 4, and slides up and down driven by the shift fork 4; The inner side of the sliding sleeve 2 is provided with several claws 9, which are distributed on the outer side of the cutter body 6 in a circular manner. The claw 9 is a cylindrical pin structure;

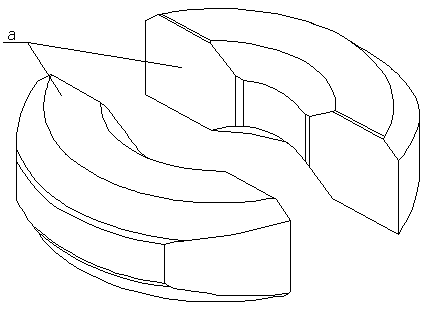

[0026] The claw 9 includes an integrally formed pin 93 and a pin cap 91, the front end of the pin 93 is provided with an arc 94 inclined to the center point of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com