Size-adjustable type high-precision machine tool clamp

A high-precision, machine tool fixture technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problem of low precision, achieve the effect of ensuring precision, reasonable design structure, and realizing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

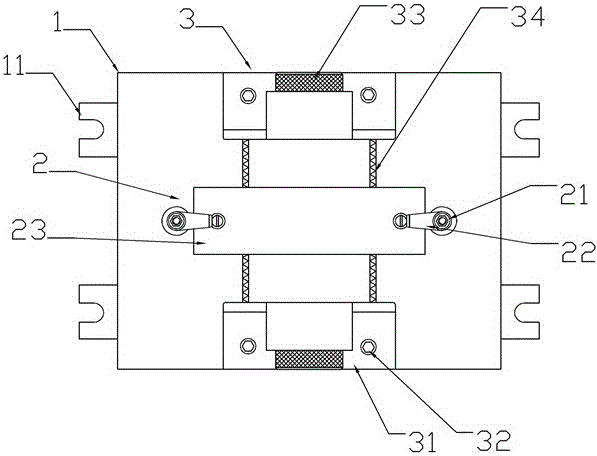

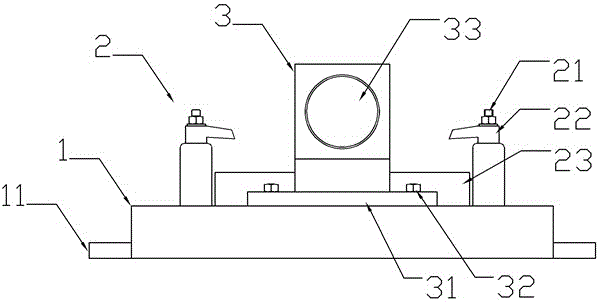

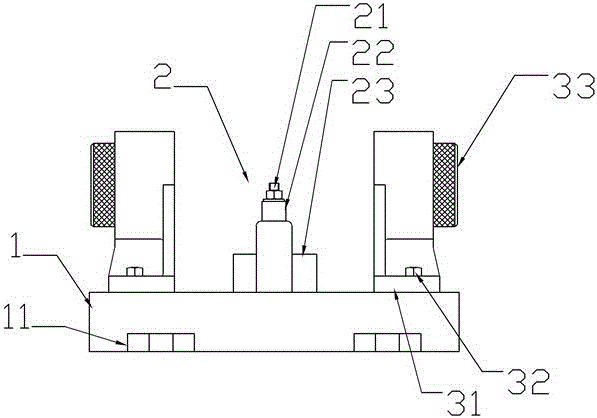

[0015] refer to figure 1 , 2 , 3, a size-adjustable high-precision machine tool fixture of the present invention includes a base 1, a fastening horizontal seat 2, and a longitudinal adjustment seat 3, and the left and right ends of the base 1 are provided with loading and unloading bolts 11; the fastening The horizontal seat 2 is arranged on the base 1 and is located at the center of the base 1; the fastening horizontal seat 2 is composed of an adjusting bolt 21, a hook-shaped pressing plate 22 and a precision carrier 23, and the adjusting bolt 21 and the hook-shaped pressing plate 22 are distributed on The left and right sides of the precision carrier 23; the adjustment bolt 21 is set on the hook-shaped pressing plate 22, and is in close contact with the hook-shaped pressing plate 22; the longitudinal adjustment seat 3 is set on the base 1, and is located in the middle of the upper and lower sides of the base 1 The longitudinal adjustment seat 3 is composed of a bearing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com