3D printing device with compact structure

A 3D printing, compact structure technology, applied in the direction of additive processing, etc., can solve the problems of poor structure compactness, wire harness winding, affecting the appearance and other problems, and achieve the effect of strong integrity, reasonable layout and good aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the technical solution of the present invention will be described in detail through specific examples.

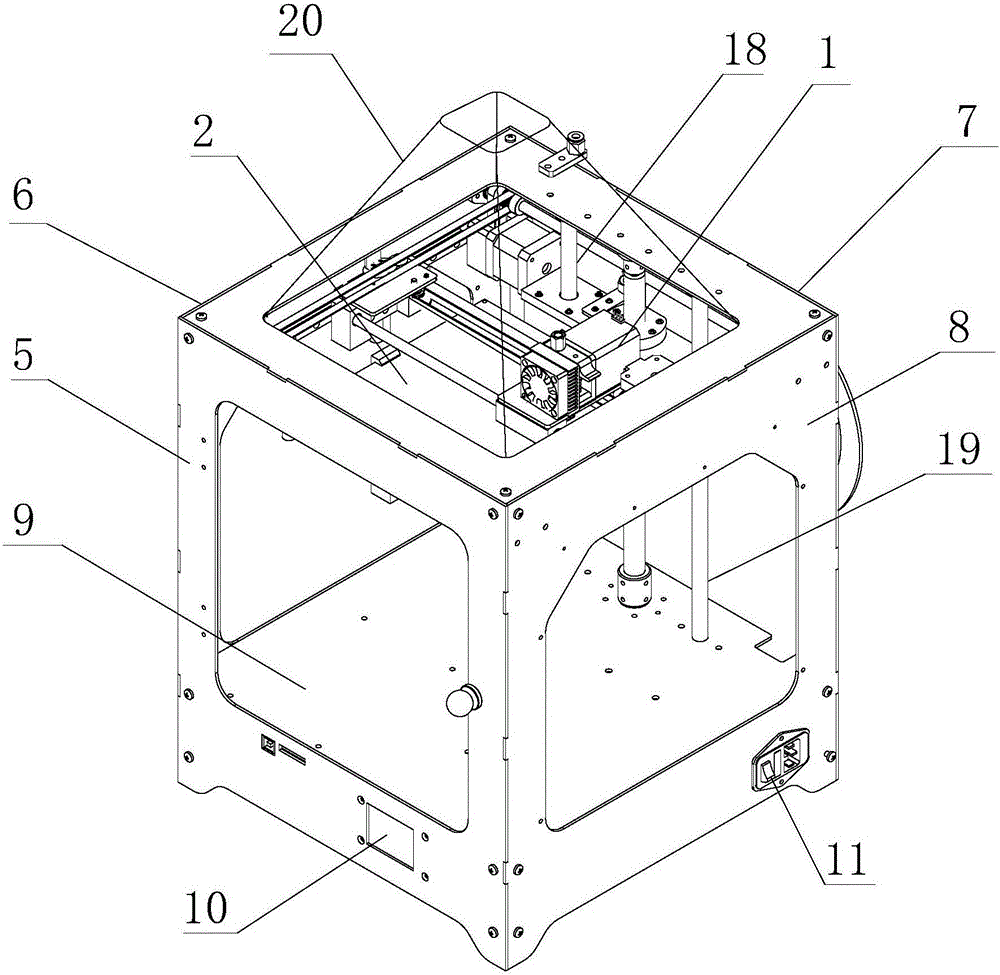

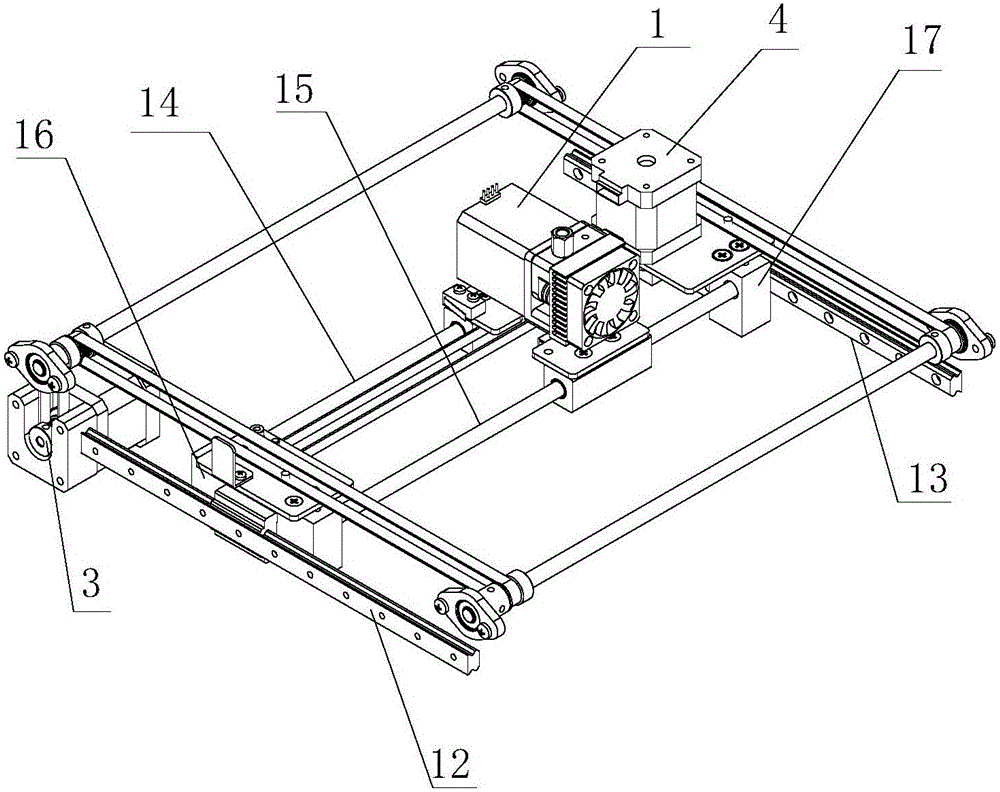

[0032] Such as Figure 1-2 as shown, figure 1 A structural schematic diagram of a compact 3D printing device proposed by the present invention; figure 2 It is a positional diagram of the first guide rail, the second guide rail, the third guide rail and the fourth guide rail in a compact 3D printing device proposed by the present invention.

[0033] refer to Figure 1-2 , a compact 3D printing device proposed by an embodiment of the present invention, including: a box body, an extruder assembly 1, a heated bed assembly 2, a first driving mechanism 3, a second driving mechanism 4, and a third driving mechanism , and a control device for controlling the extrusion assembly, the hot bed assembly 2, the first drive mechanism 3, the second drive mechanism 4, and the third drive mechanism, wherein:

[0034] The box body includes a bottom panel, a top panel, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com