Upper injection molding mold

A technology for injection molding and shoe uppers, which is applied to footwear, home appliances, and other home appliances. It can solve problems such as unsatisfactory requirements, increased mold manufacturing costs, and limited shoe aesthetics, so as to achieve rich variety and expand Consumer groups, the effect of enriching appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

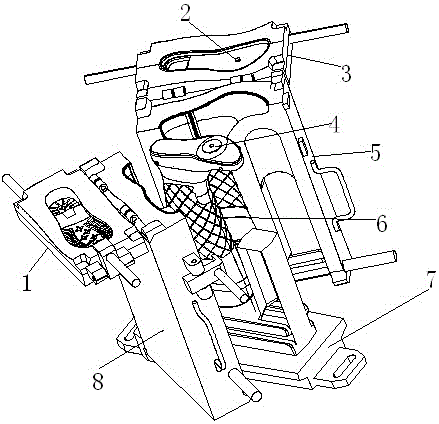

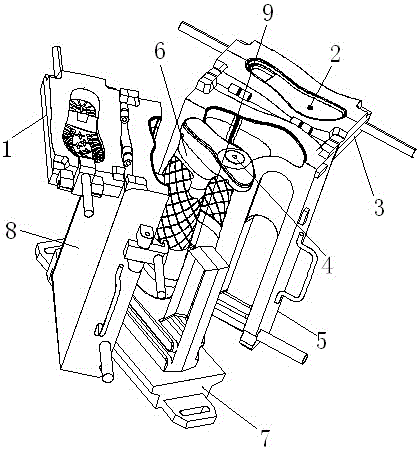

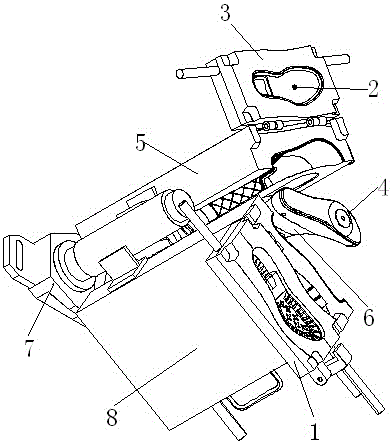

[0024]As shown in the figure, the shoe upper injection molding mold is mainly carried out through the forming mold, and some actions on the forming mold are mainly carried out manually, including the base 7, the left movable mold 8 and the right movable mold 5 are hinged at one end of the base 7 On the side, an inner last 6 is fixed at the middle position of the base 7 . The surfaces facing each other of the left movable mold 8 and the right movable mold 5 are symmetrically provided with mold cavities, and the mold cavities wrap the inner last 6 after mold closing. The free ends of the left movable mold 8 and the right movable mold 5 are provided with fastening structures. After closing the molds, the fastening structure is operated to fasten the left movable mold 8 and the right movable mold 5 together.

[0025] Forming mold also can not comprise base 7, and left movable mold 8 and right movable mold 5 are respectively directly fixed on the power mechanism on the automatic sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com