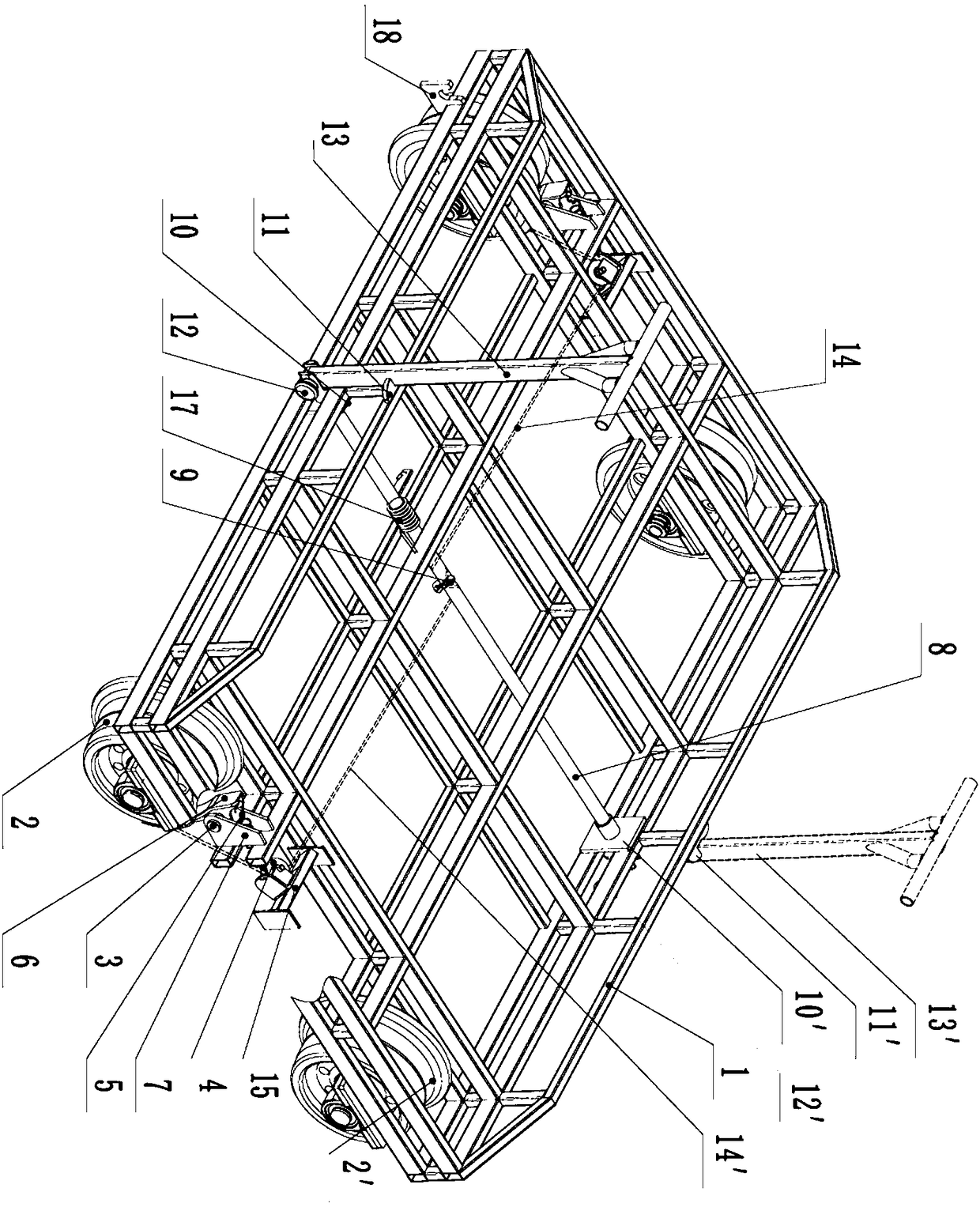

An automatic parking brake type railway track trolley

A railway track and parking brake technology, applied in the field of automatic parking brake type railway track trolleys, can solve problems such as safety accidents, no automatic brake parking function, etc., and achieve the effects of large load capacity, light brake release and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

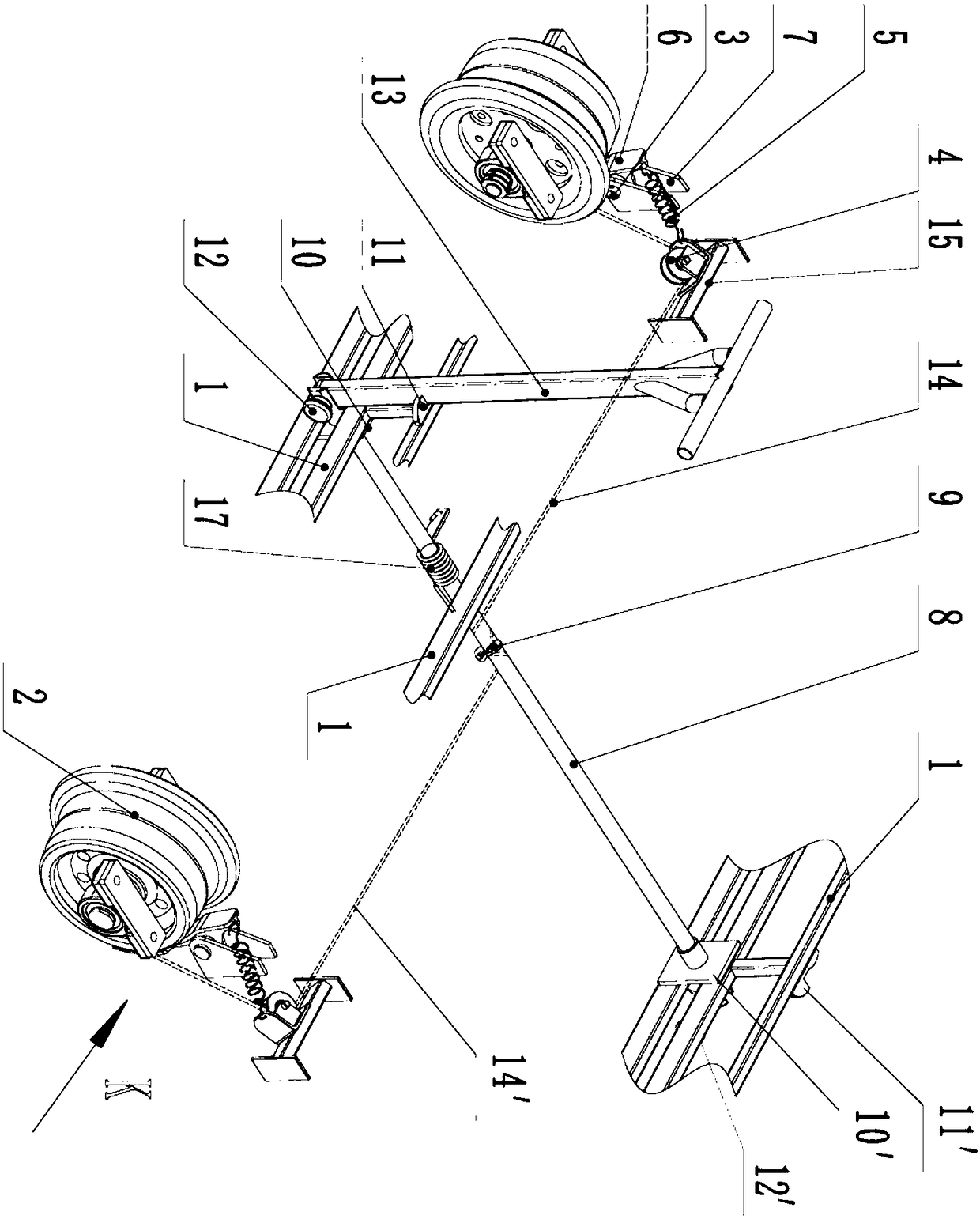

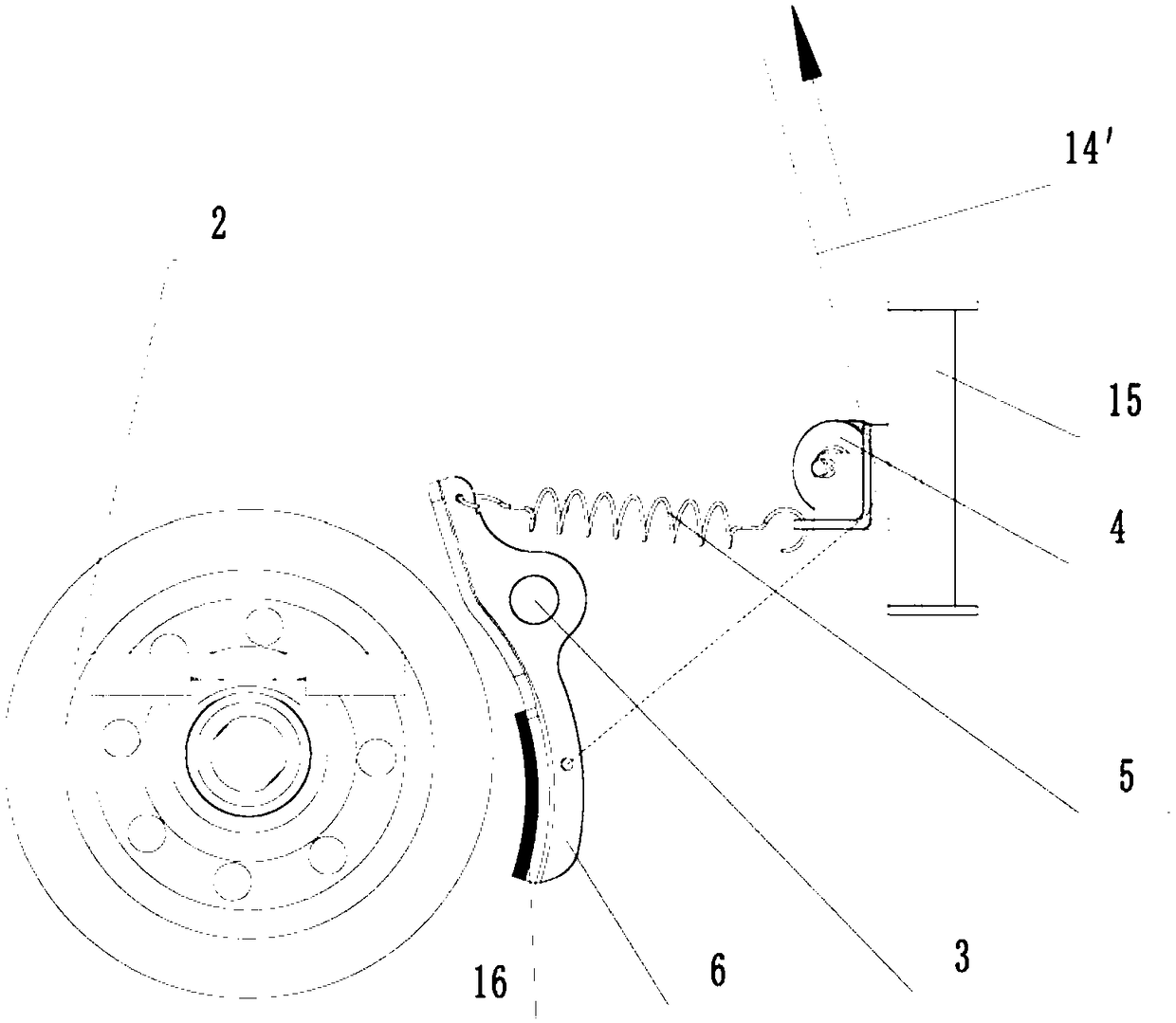

[0012] Such as figure 1 As shown, under the normal state of parking, the brake pads 16 attached to the brake pad bracket 6 tightly embrace the track roller 2 under the action of the tension spring 5, so that the whole vehicle is in a static state; when normal operation is required, the staff The hand push rod 13 must be rotated 90° clockwise to make it in an upright position, and the brake torsion shaft 8 is driven to rotate 90°. The brake pad positioning piece 9 fixed together with the torsion shaft 8 also rotates 90° thereupon, and the left and right soft steel wires 14, 14' connected with it are pulled to drive the brake pad bracket 6 to rotate around the pin shaft hinge 3, so that the brake pad 16 is detached from the track roller 2 wheels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com