Ship bow anchor system design anchor weighing and dropping model verification method

A model verification and mooring technology, applied in ship design, calculation, ship construction, etc., can solve the problems of no combination of 3D software design and manufacturing, long manufacturing cycle, cumbersome part model processing and modification, etc., to save design cycle, improve design efficiency, and facilitate technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

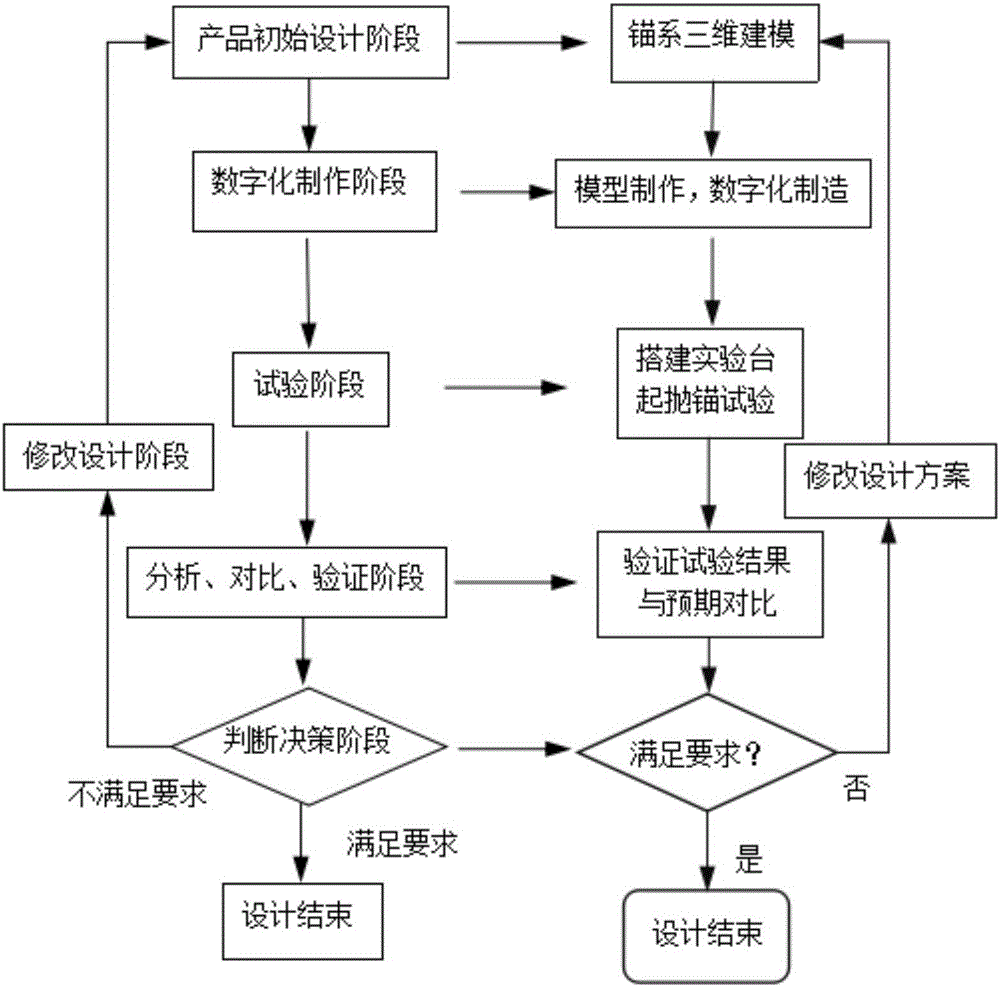

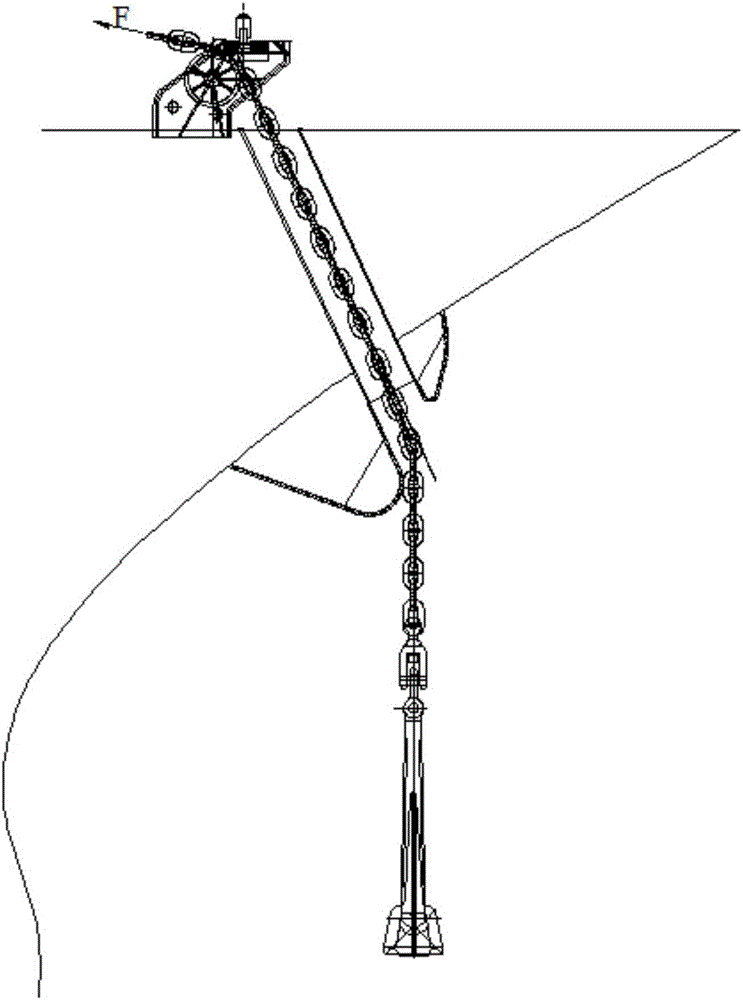

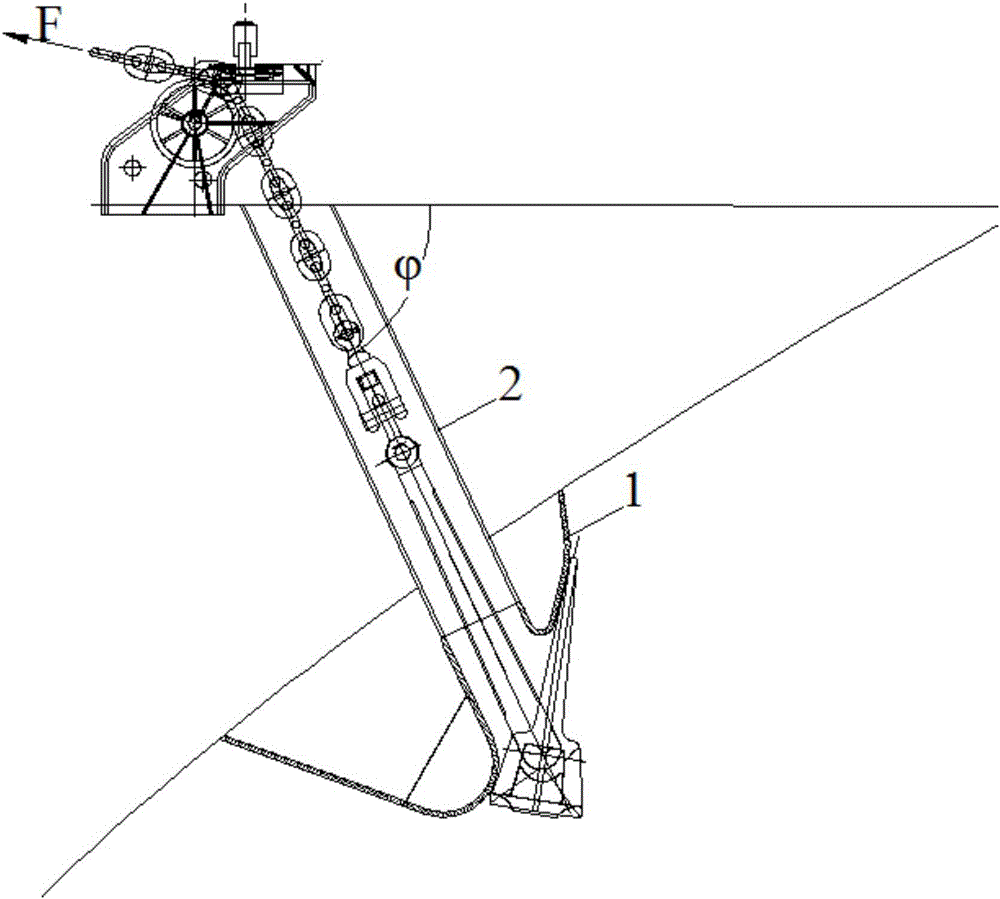

[0022] Such as Figure 1 to Figure 3 As shown, a method for verifying the anchor handling model of bow mooring system design in this embodiment includes the following steps in turn:

[0023] (1) Initial design: UG, Pro / E, SolidWorks and other digital 3D software are used to establish a solid model, that is, to design the part model required in the anchor system experiment through computer technology, and to give the material properties of the part while ensuring the appearance of the part . The material selection of the part model should be based on the test purpose and test requirements. The size ratio of the part model should be selected according to the test environment, test site and equipment performance. In actual manufacturing, the ratio of 1:1, 1:2, and 1:5 can be selected. . If conditions permit, try to prototype the part model to simulate the actual movement situation;

[0024] (2) Digital manufacturing of the model: Import the file containing the complete informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com