Brick conveying device with counting function

A technology for conveying devices and bricks, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyors. It can solve the problems of bricks being unevenly stressed, shaking, and difficult to adjust, so as to improve quality and yield, Avoid shaking and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

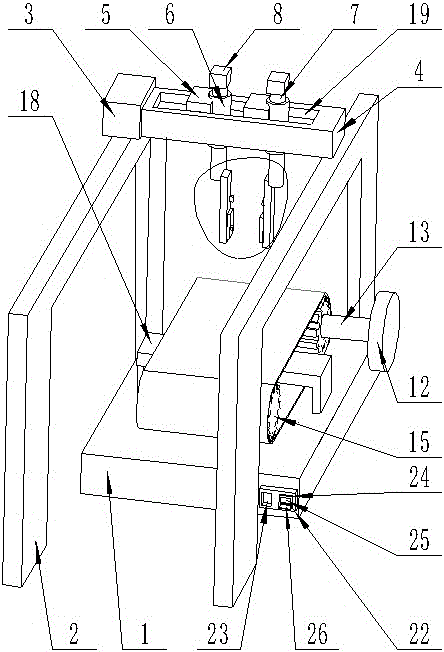

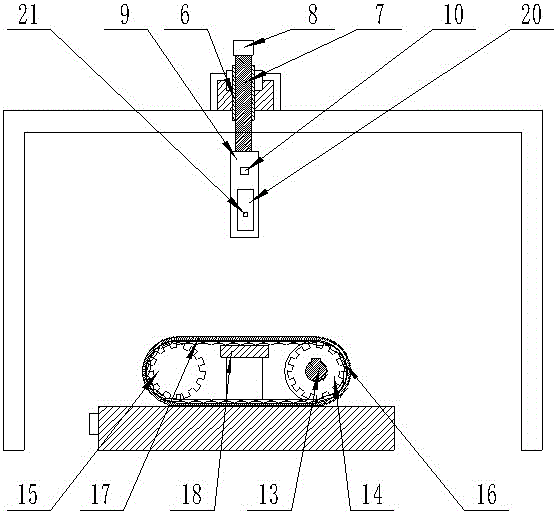

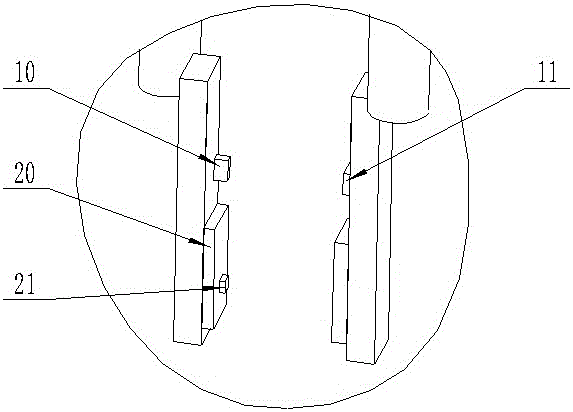

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a brick conveying device with counting function, including a frame body (1), is characterized in that, the frame body (1) is provided with a transmission unit, and the frame body (1) is provided with There is a pair of adjustment frames (2), and a clamping unit is arranged on the pair of adjustment frames (2). The valve box (3) is fixedly connected, and the other end of the connecting beam (4) is movably connected to the other adjustment frame (2), a pair of telescopic clamp arms arranged on the connecting beam (4), and a pair of telescopic clamps respectively driven The No. 1 hydraulic pump (5) whose arm moves along the length direction of the connecting beam (4) is jointly composed of a pair of telescopic clamp arms that are arranged on the connecting beam (4) and can move along the length direction of the connecting beam. The sliding sleeve (6), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com