Method for designing components of high-entropy alloy based on segregation condition among components

A high-entropy alloy and composition design technology, applied in the field of high-entropy alloy composition design, can solve problems that cannot be used to explain the formation of high-entropy alloys, single solid solution structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

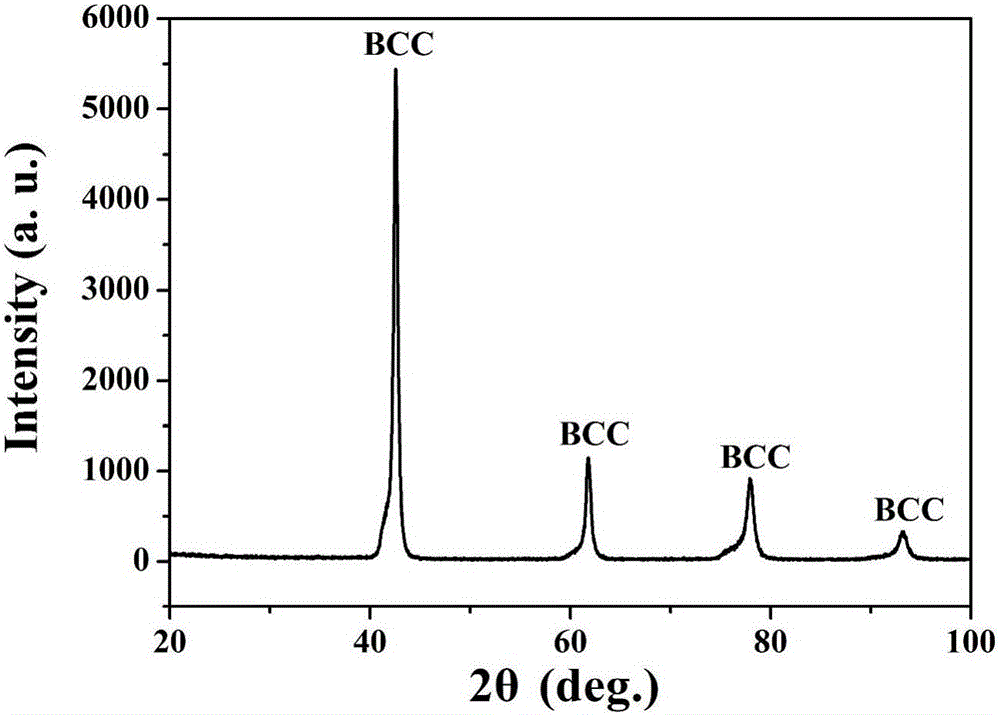

[0052] VMoCrMn high entropy alloy

[0053] (1) Calculation of the interaction energy between elements: select V, Mo, Cr, Mn, the four transition group elements, and carry out alloying at an equal atomic ratio, and calculate the I between each component by the above formula (9) ij , and the calculation results are listed in Table 1.

[0054] Table 1 Interaction energy I between components ij (KJ·mol -1 )

[0055]

[0056] (2) Judging the segregation of components: Judging the segregation of components according to each interaction energy value: a) The interaction energy of all components in the high-entropy alloy with equal atomic ratio satisfies -I t ij t , I t I that forms a solid solution for the alloy ij The limit value of the alloy tends to form a solid solution with a single structure;

[0057] b) When there is an interaction energy I between components ij > I t , the segregation of similar components will appear in the alloy;

[0058] c) There is an interacti...

Embodiment 2

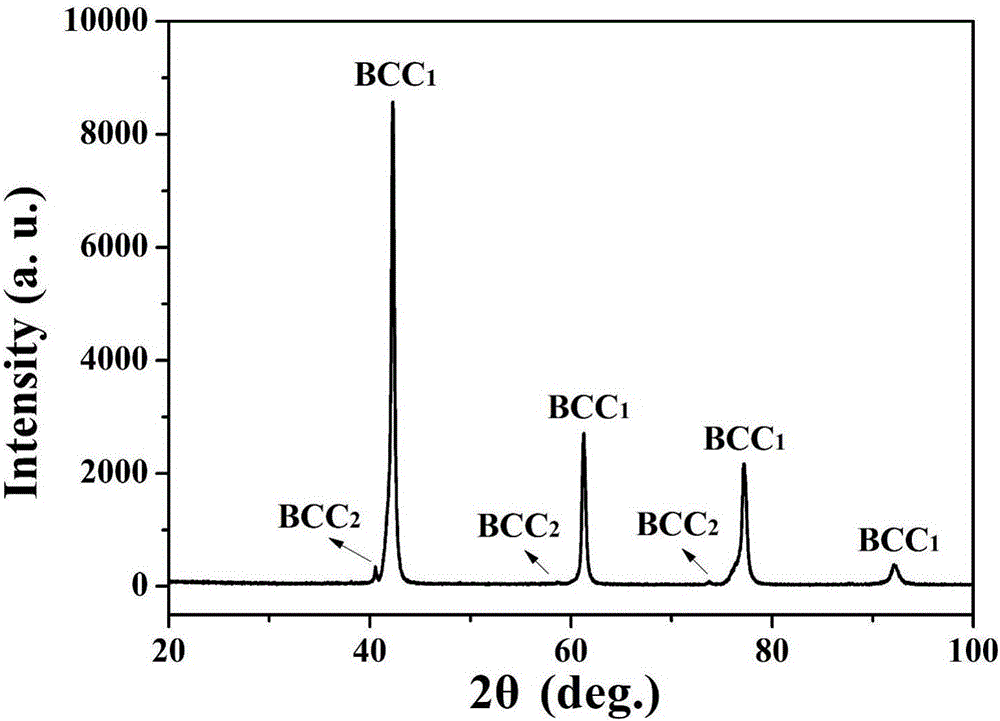

[0064] VMoCrAlMn high entropy alloy

[0065] (1) Calculation of the interaction energy between elements: select five elements V, Mo, Cr, Al, and Mn, alloy them in an equal atomic ratio, and calculate the I between each component by formula (9) ij , and the calculation results are listed in Table 2.

[0066] (2) Judging the segregation of components: judge according to the situation described in the examples.

[0067] In this embodiment, the interaction energy between each component of the composition has the I of Al-V and Al-Cr ij values much less than zero, I AlV =-43.0KJ·mol -1 , I AlCr =-47.8KJ·mol -1 , so the alloy should precipitate a second phase or form a new solid solution phase between the grain boundaries.

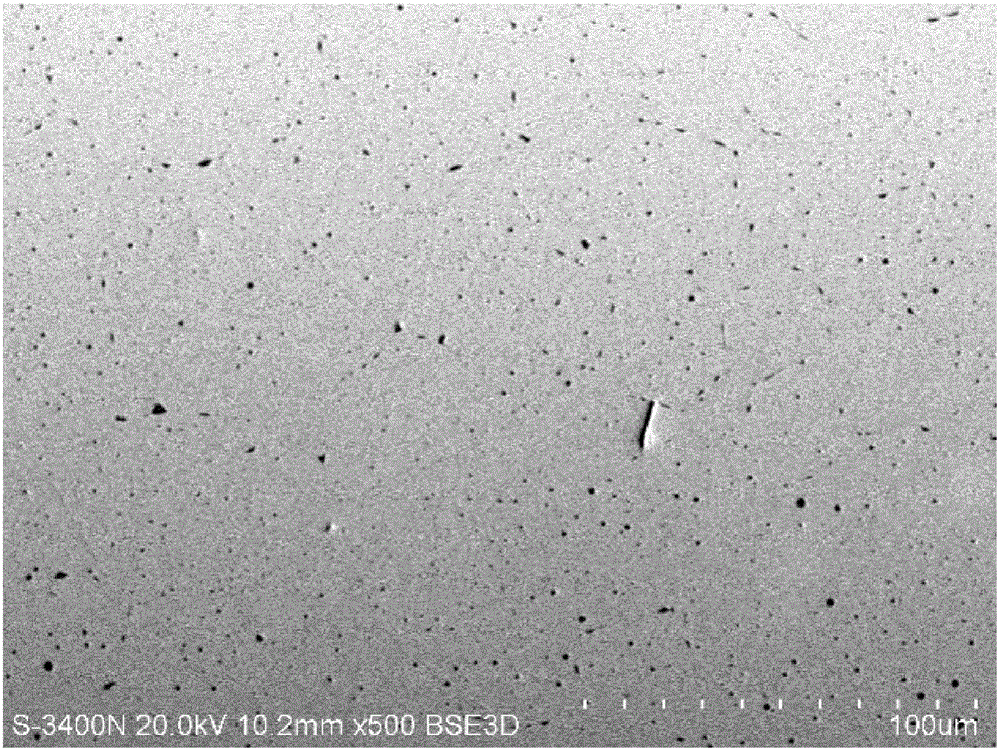

[0068] (3) Composition design of the high-entropy alloy: design the composition of the high-entropy alloy according to the required structure, and the atomic percentages of each component are: V20%, Mo20%, Cr20%, Al20%, Mn20%, after conversion into weight...

Embodiment 3

[0072] NiMnFeCu High Entropy Alloy

[0073] (1) Calculation of the interaction energy between elements: select the four elements Ni, Mn, Fe, and Cu, alloy them with an equal atomic ratio, and calculate the I between each component by formula (9) ij , and the calculation results are listed in Table 3.

[0074](2) Judging the segregation of components: judge according to the situation described in the examples.

[0075] In this embodiment, only the I of Ni-Mn is included in the interaction energy between the components ij values much less than zero, I NiMn =-44.3KJ·mol -1 , so the alloy should precipitate a second phase or form a new solid solution phase between the grain boundaries.

[0076] (3) Composition design of the high-entropy alloy: design the composition of the high-entropy alloy according to the desired structure, the atomic percentages of each component are: Ni25%, Mn25%, Fe25%, Cu25%, and the ingredients are converted into weight percentages. The present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com