Preparation method for curved-surface composite material preform

A technology of composite materials and manufacturing methods, applied in fabrics, textiles, textiles, and papermaking, etc., can solve problems such as complex manufacturing processes, unsatisfactory internal quality of products, and poor uniformity of fabric density, so as to simplify the molding process and ensure internal quality , Improve the effect of density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A method for manufacturing a curved surface composite material prefabricated body, comprising the following steps:

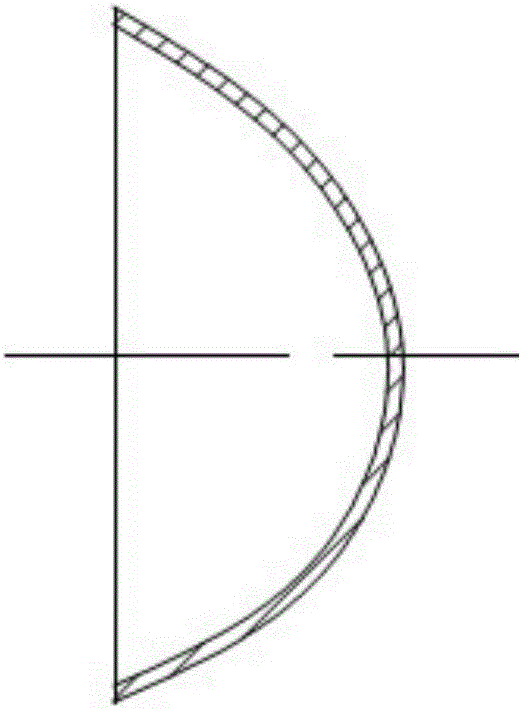

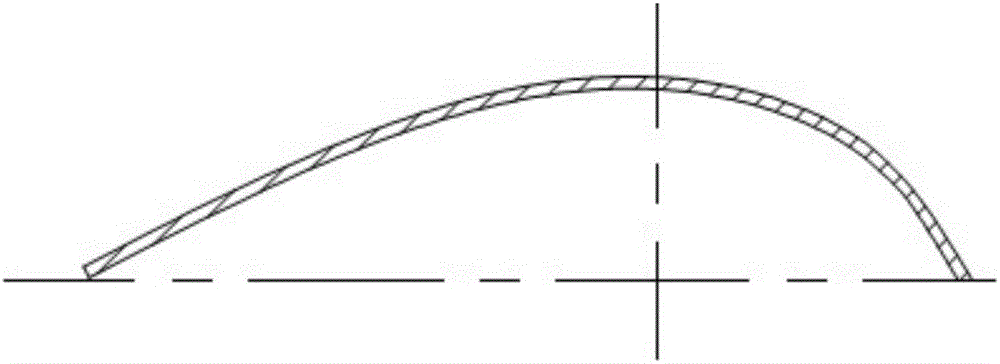

[0022] a. Make molds, molds and such as figure 1 , 2 It coincides with the inner surface of the curved composite material prefabricated body shown in 3.

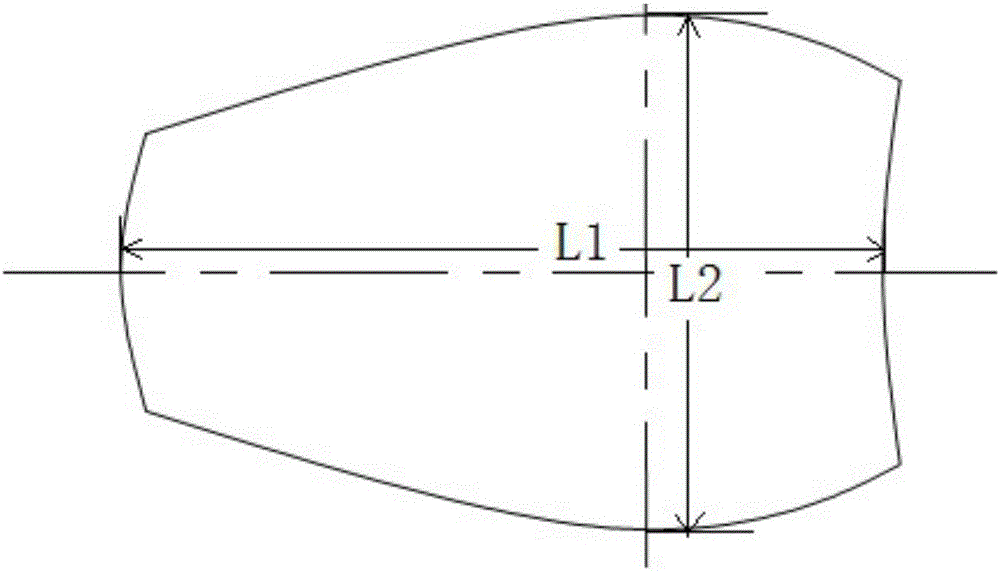

[0023] b. Measure the longest generatrix length L1 in this direction in the length direction of the mould, and measure the longest generatrix length L2 in this direction in the width direction of the mould.

[0024] c, make the planar three-dimensional fabric that is interwoven by warp yarn 1 and weft yarn 2, the longest generatrix length L1 on the length direction and the longest generatrix length L2 on the width direction are the basis of the cloth length and the width of the planar three-dimensional fabric Then reserve a certain margin at the two ends of the warp direction and the two ends of the weft direction, and the margin is used as the basis for pulling the yarn in the subsequent steps.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com