Light source device and projector

A light source device and light beam technology, applied in projection devices, optics, instruments, etc., can solve problems such as increased manufacturing costs, unfavorable light source devices or miniaturized installation layout of light source devices for projectors, invalid light cannot be used, etc., to achieve control of production Cost, the effect of improving light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

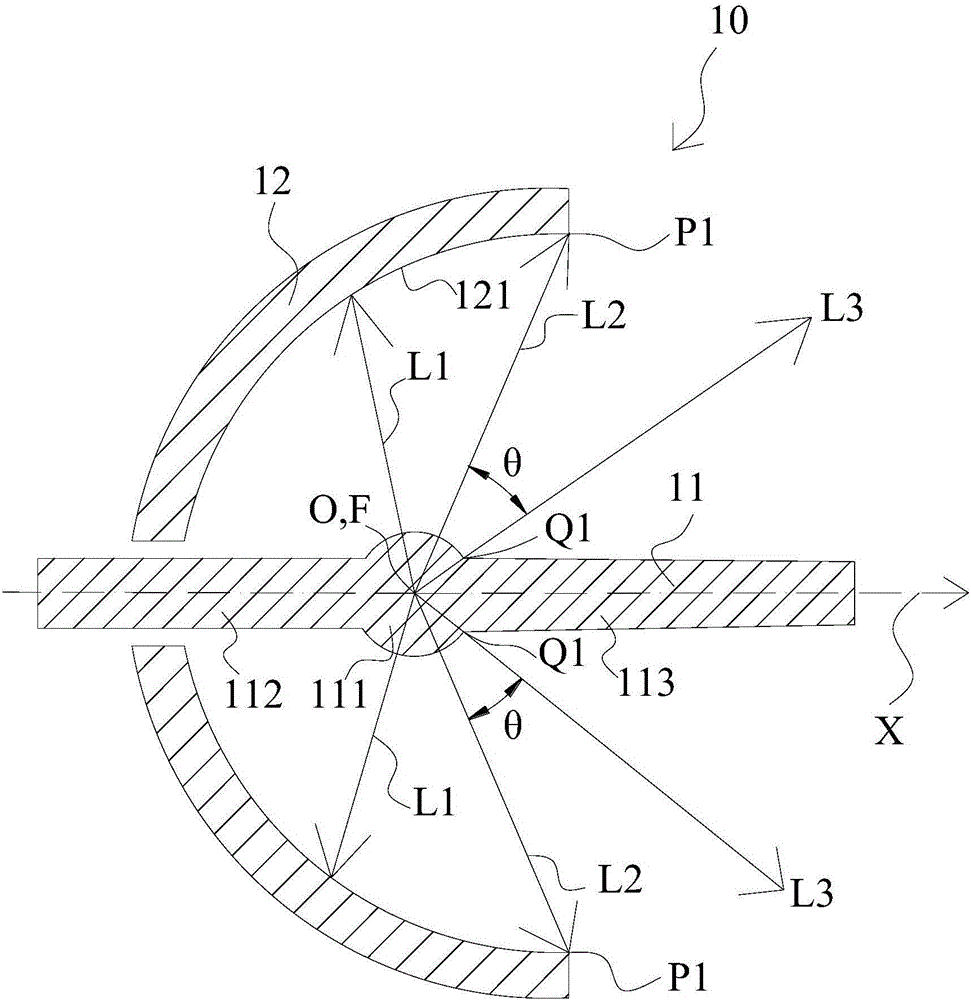

Embodiment 1

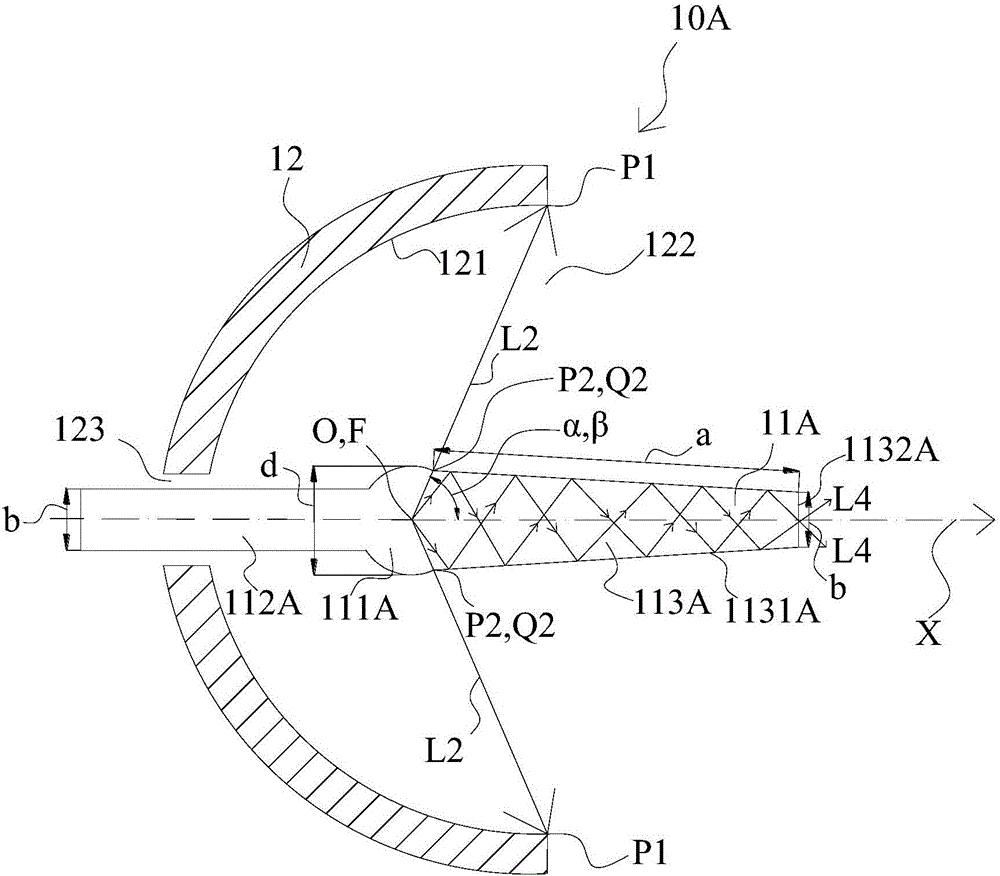

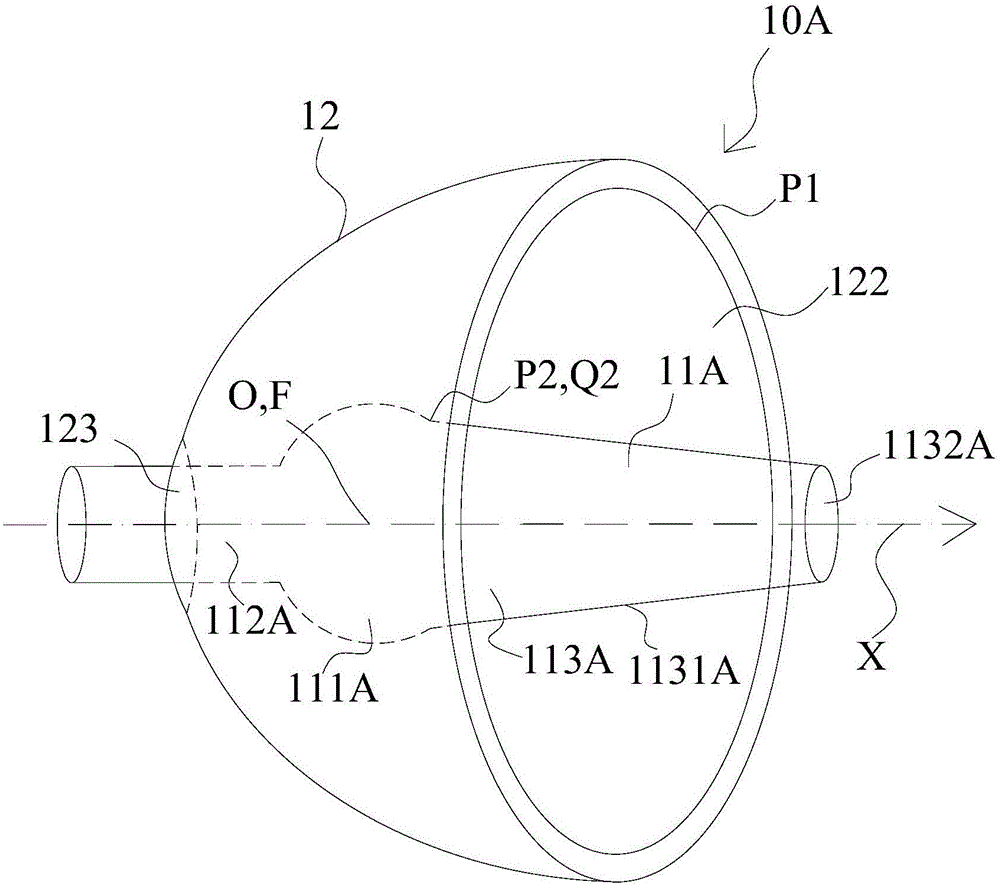

[0026] Embodiment 1 of the present invention will be described below with reference to the drawings. figure 2 is a schematic cross-sectional view of the structure of a light source device 10A provided in Embodiment 1 of the present invention, image 3 It is a three-dimensional schematic diagram of the structure of a light source device 10A provided in Embodiment 1 of the present invention, Figure 4 It is a three-dimensional schematic diagram of the structure of a light emitting tube 11A of a light source device 10A provided in Embodiment 1 of the present invention.

[0027] Such as figure 2 and image 3 As shown, the light source device 10A includes a luminous tube 11A and a reflector 12 that reflects the beam emitted by the luminous tube 11A. The luminous tube 11A is located inside the reflector 12. In other words, the light source device 10A adjusts the beam emitted from the luminous tube 11A to A device that shoots out in a certain direction. In addition, in the pres...

Embodiment 2

[0043] Embodiment 2 of the present invention will be described below with reference to the drawings. Figure 5 It is a schematic cross-sectional view of the structure of a light source device 10B provided in Embodiment 2 of the present invention.

[0044] In the following description, the same structure and the same components as those of the above-mentioned first embodiment are given the same reference numerals, and their detailed descriptions are omitted or simplified.

[0045] In Example 2, such as Figure 5 As shown, the light source device 10B includes a luminous tube 11B and a reflector 12 that reflects the light beam emitted by the luminous tube 11B. The luminous tube 11B is located inside the reflector 12. In other words, the light source device 10B adjusts the light beam emitted from the luminous tube 11B to A device that shoots out in a certain direction. In addition, in the present invention, the light beam emitting direction of the light source device 10B is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com