Output-based self-adaptive intelligent production method

An intelligent production and self-adaptive technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve the problems of complex line clearing process, reduction of production line production efficiency, and tediousness, so as to improve production efficiency, realize intelligent production, The effect of reducing the time to clear the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

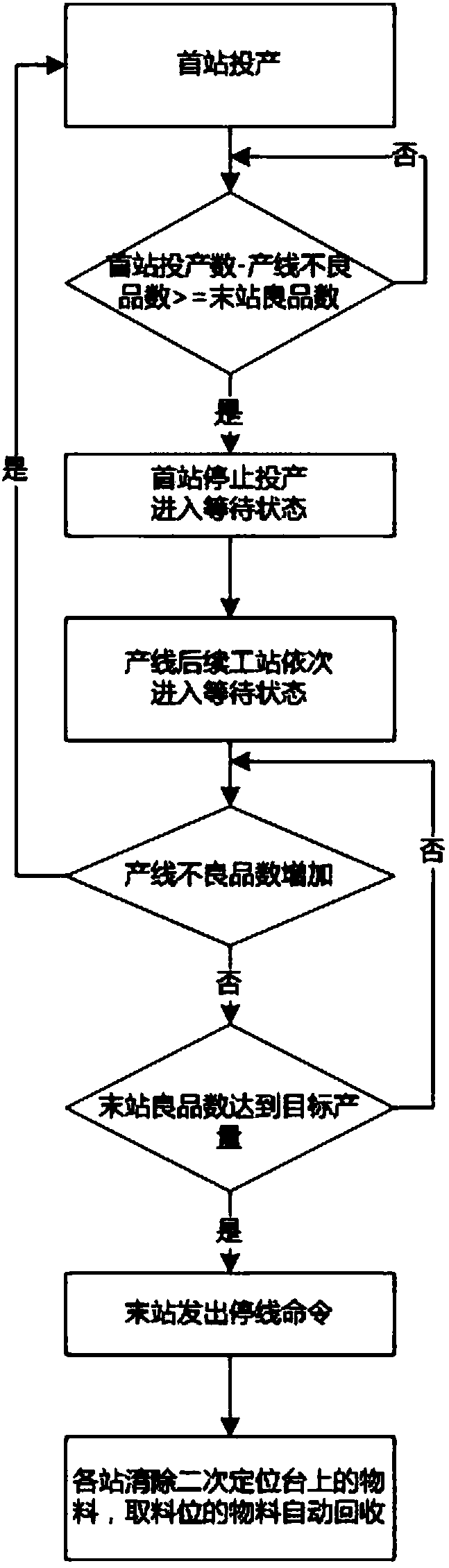

[0026] Such as figure 1 As shown, an adaptive intelligent production method based on output of this embodiment includes the following steps:

[0027] S1: Real-time monitoring of production conditions at each station of the production line;

[0028] S2: Determine whether the production line needs to enter the waiting state;

[0029] S3: Determine whether the first station needs to make a supplementary investment;

[0030] S4: Determine whether to stop the line;

[0031] S5: The production line is stopped, and each station automatically removes objects;

[0032] Among them, S1 specifically includes the following steps:

[0033] Set the target output as A, open the production line, and the production line control system monitors the production status of each station of the production line in real time via Ethernet. Among them, the number of production lines at the first station is B, the number of good products at the last station is C, and the number of defective products on the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com