Integrated C-shaped wire clamp

A technology of creating through wires and clamping seats, applied in the direction of clamping/spring connection, electrical components, circuits, etc., which can solve the problems of untargeted loosening, inconvenient operation, and inability to achieve the effect of overcoming the cumbersome installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

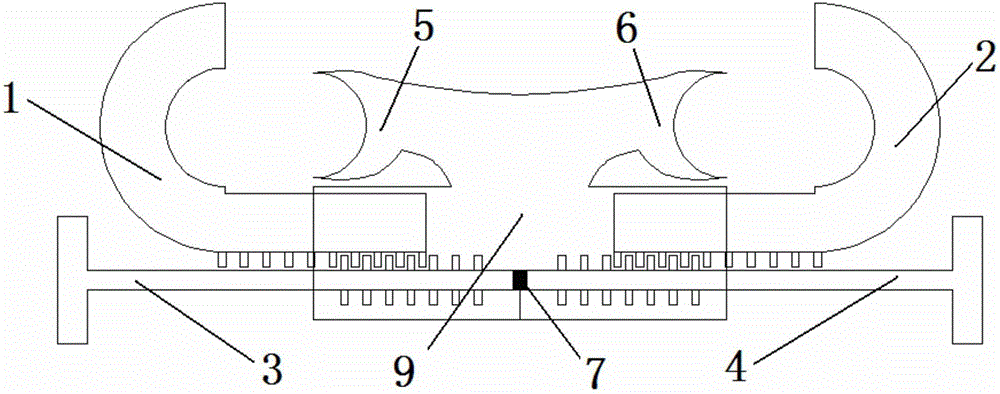

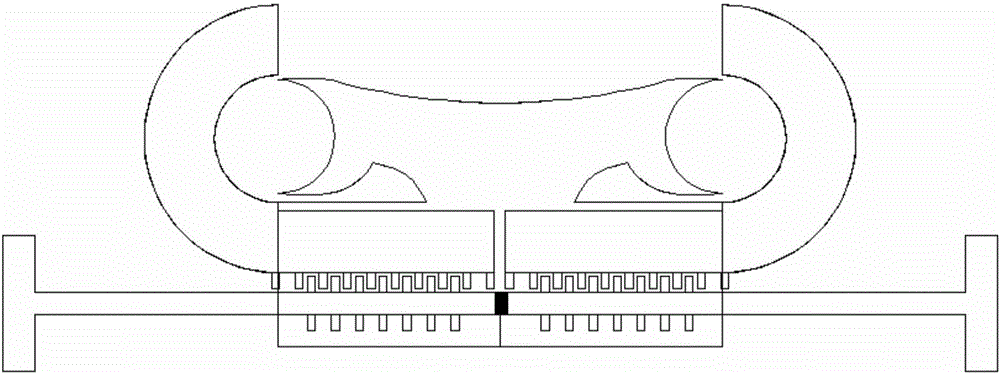

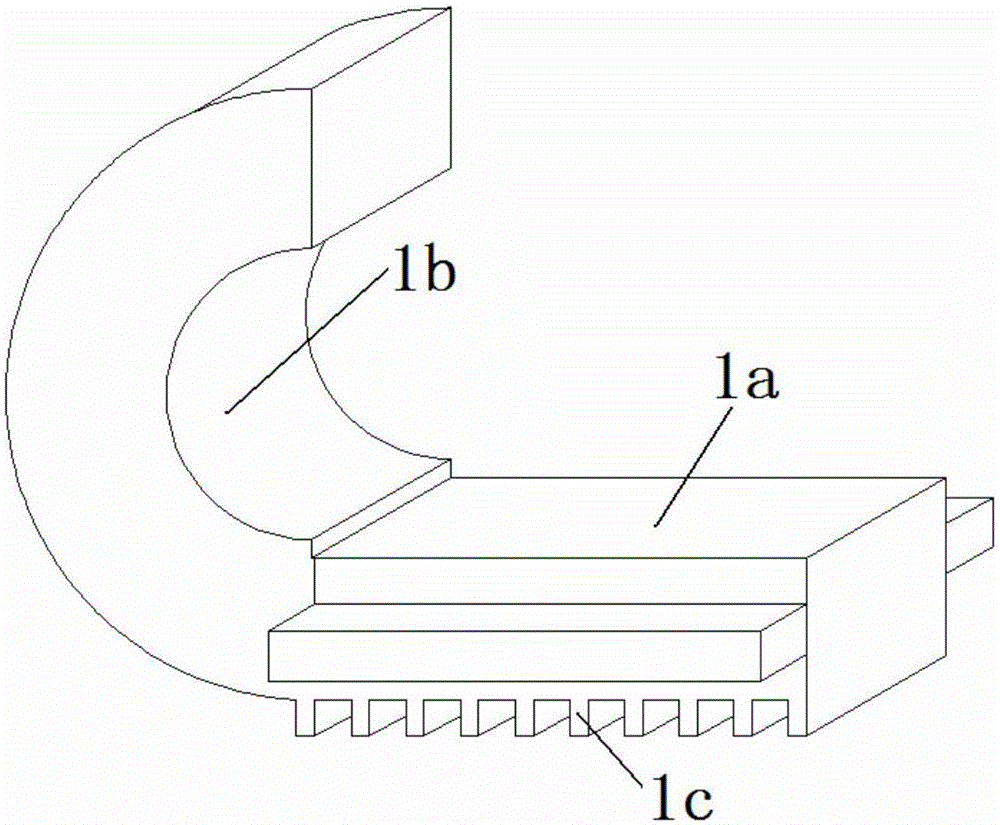

[0022] An integrated Chuangtong clamp, including a clamp seat, a J-shaped left movable clamp block 1, a J-shaped right movable clamp block 2, a left screw rod 3 and a right screw rod 4,

[0023] Described holder comprises left fixed wire slot arm 5, right fixed wire slot arm 6 and box-shaped base 9, and left fixed wire slot arm 5 and right fixed wire slot arm 6 are fixed on the top of box-shaped base 9,

[0024] There are multiple rows of teeth 1c below the straight part of the J-shaped left movable clamp block 1 and the J-shaped right movable clamp block 2, and are respectively installed in the inner cavity of the box-shaped base 9 from both ends thereof,

[0025] Described left screw rod 3 and right screw rod 4 are respectively installed in its inner cavity from the two ends of box-shaped base 9, and the screw teeth of left screw rod 3 and right screw rod 4 are connected with J-shaped left movable clamp block 1 and J-shaped right movable clamp block respectively. 2 Teeth mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com