An automatic feedback control system for buffering sudden temperature changes of dry-type reactors

A dry-type reactor and automatic feedback technology, which is applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems such as equipment burnout, and achieve the effects of prolonging life, small footprint, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

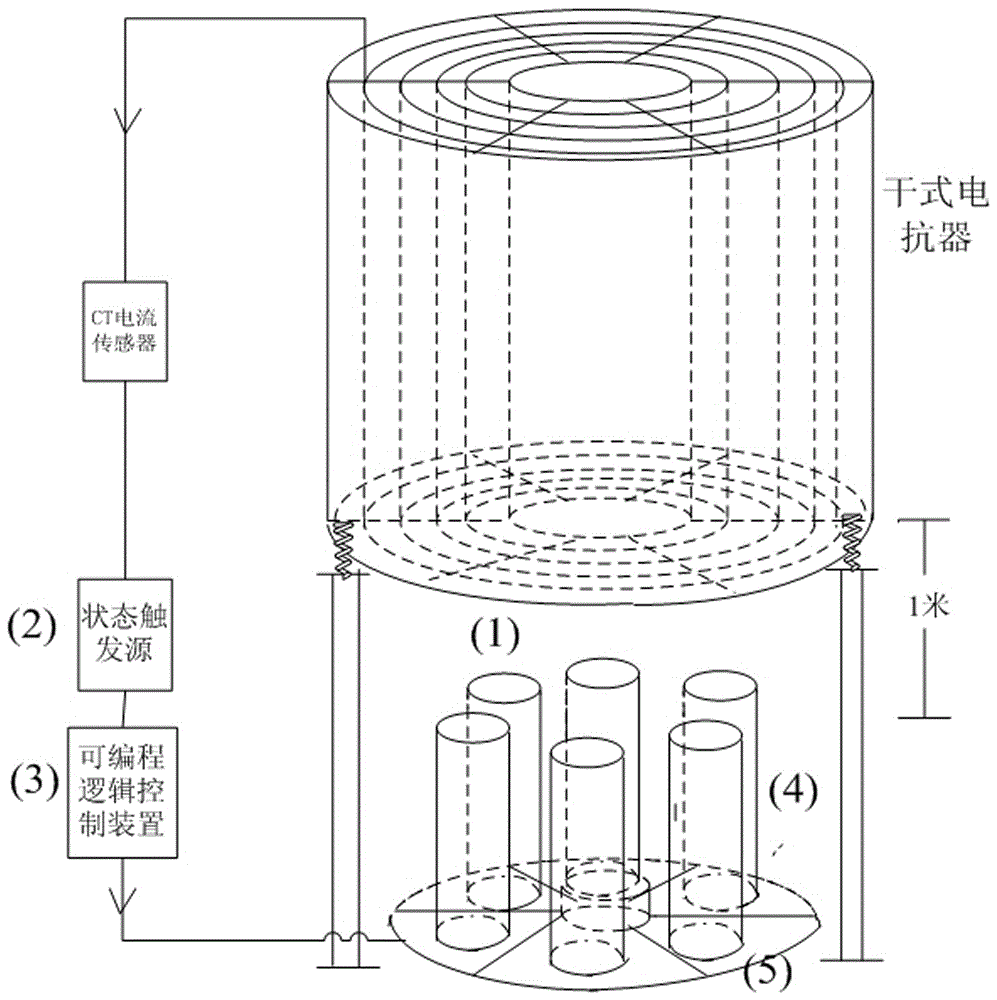

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic feedback control system for buffering sudden temperature changes of dry-type reactors, the present invention is characterized in that the system is sequentially connected by a state trigger source 2, a programmable logic control device 3, and an axial flow fan body 1;

[0029] in,

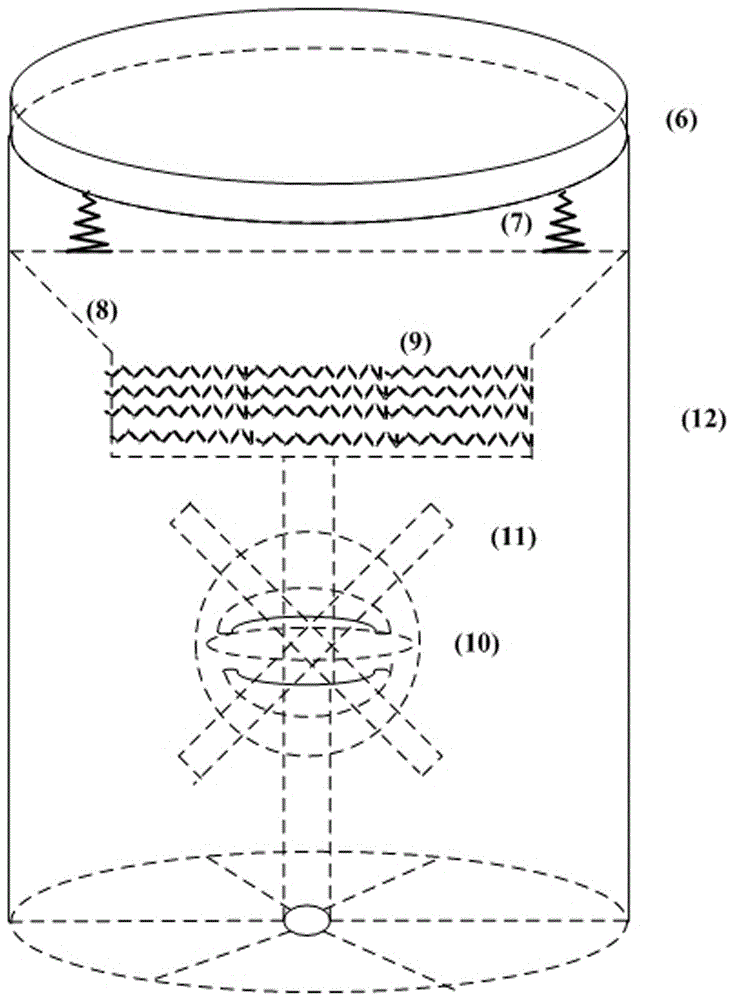

[0030] The fan body 1 is composed of a distributed fan 4 and a bracket device 5 arranged at the bottom of the distributed fan 4, and the distributed fan 4 is fixed on the bracket device 5; The windshield 6 of the tuyere, the automatic control spring 7 that is arranged on the top of the mica sheet 8 and connected with the windshield 6, the high-power heating wire 9 installed inside the mica sheet 8, and the bottom of the mica sheet 8 connected with the bottom of the housing 12 The supporting column is composed of an electromagnetic speed-regulating motor 10 arranged on the supporting column, and a fan blade 11 inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com