Reactive silicone composition, hotmelt material made therefrom, and curable hotmelt composition

一种反应性有机硅、热熔材料的技术,应用在半导体/固态器件零部件、半导体器件、胶粘剂等方向,能够解决热熔性能不足等问题,达到优异瞬时和永久性粘附性能、优异架藏稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0084] The reactive silicone composition, hot melt material, and curable hot melt composition of the present invention will be further described in more detail with reference to practical examples and comparative examples. In the formula, Me, Vi, and Ep correspond to methyl, vinyl, and 3-glycidyloxypropyl, respectively.

[0085] [Practical example 1]

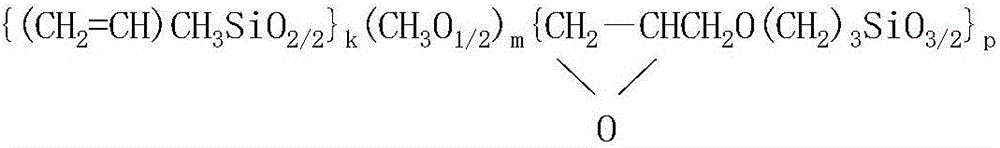

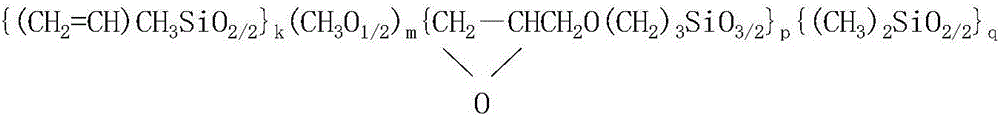

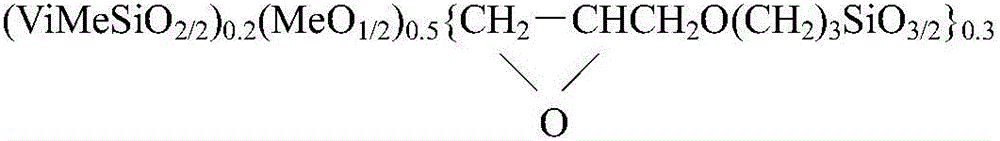

[0086] A reactive silicone composition was prepared by mixing 32.5 parts by mass of an organopolysiloxane resin represented by the following average unit formula:

[0087] (ViMe 2 SiO 1 / 2 ) 0.11 (Me 3 SiO 1 / 2 ) 0.33 (SiO 4 / 2 ) 0.56 (HO 1 / 2 ) 0.02

[0088] 32.5 parts by mass of an organopolysiloxane resin represented by the following average unit formula:

[0089] (Me 3 SiO 1 / 2 ) 0.44 (SiO 4 / 2 ) 0.56 (HO 1 / 2 ) 0.02

[0090] 28.0 parts by mass of diorganopolysiloxane represented by the following average formula:

[0091] Me 3 SiO(Me 2 SiO) 789 (MeViSiO) 11 SiMe 3

[0092]5.0 parts by mass of organohydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com