A kind of preparation method of plant tissue protein

A plant tissue and production method technology, applied in food science, food forming, application and other directions, can solve the problems of difficult to clean up remaining pulp, waste of raw materials, etc., and achieve high soluble protein and NS value, good water solubility, and gluten. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

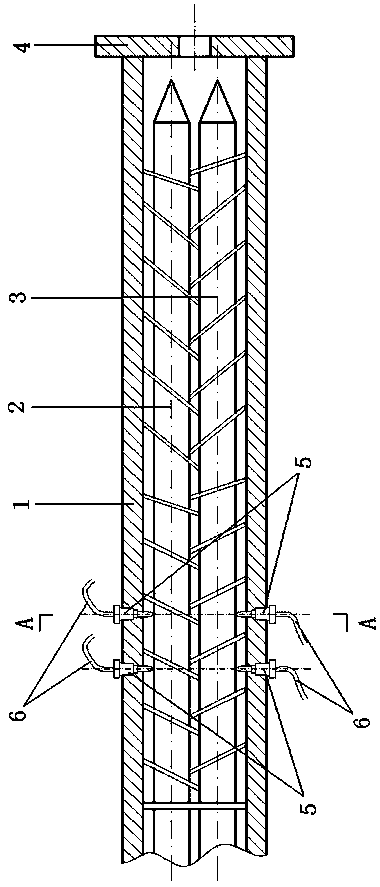

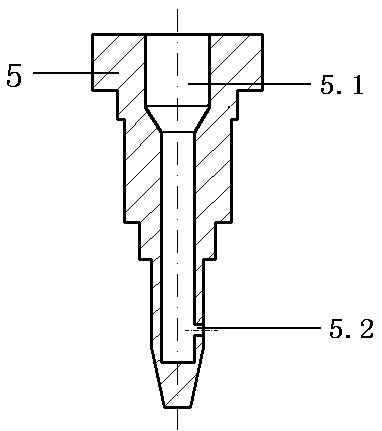

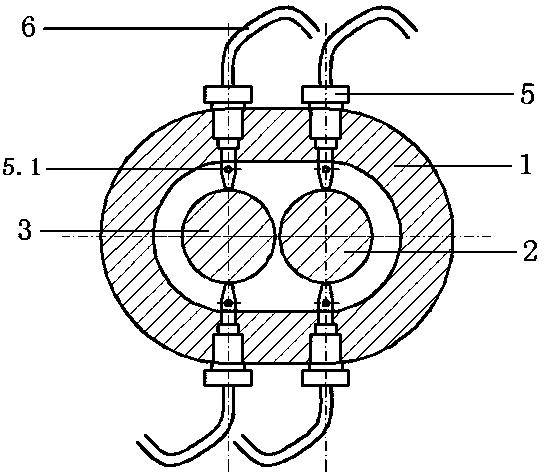

Image

Examples

Embodiment 1

[0032] A method for preparing plant tissue protein, said plant tissue protein comprising plant tissue protein material powder and water;

[0033] The raw materials and their mass fractions in the plant tissue protein powder are: soybean protein isolate powder 35%; edible low-temperature soybean meal 30%; gluten powder 15%; wheat starch 5%; corn starch 5%; peanut protein powder 5% %; red bean powder 5%;

[0034] The mass ratio of described vegetable tissue protein powder and water is 2:1;

[0035] The preparation method of described plant tissue protein is prepared according to the following steps:

[0036] Step 1) Stirring: Accurately weigh each raw material in the plant tissue protein powder according to its mass fraction, and put it into a mixing tank with a seal. Inside the molding machine;

[0037] Step 2) Set the processing temperature of the special screw forming machine: the special screw forming machine is provided with a temperature zone, a second temperature zone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com