Filtering plate

A filter plate and main board technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems affecting the filtration efficiency of filter presses, and achieve the effects of simple structure, guaranteed filtration efficiency, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

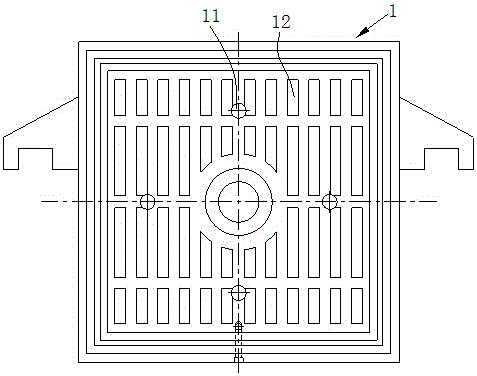

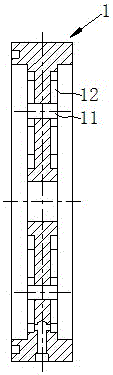

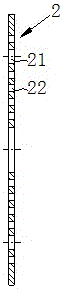

[0021] A filter plate, including a filter main board 1, see figure 1 , figure 2 , set recessed areas on both sides of the filter main board 1 to form filter chambers, refer to image 3 , Figure 4 , the filter plate also includes a porous plate 2, the porous plate 2 is installed in the filter chamber, a support member 12 is arranged between the porous plate 2 and the filter chamber, and the cavity between the porous plate 2 and the filter chamber forms a filtrate chamber; in this implementation In one example, the support 12 is fixedly arranged on the bottom surface of the chamber.

[0022] When filtering, the filtrate produced by filtration can enter the filter chamber through the through hole 22 on the porous plate 2. The size of the through hole 22 on the porous plate 2 can be processed according to different materials and filtration pressures. The optimum diameter of the through hole 22 The range is between 1 mm and 10 mm, and the diameter of the through hole 22 is 1 m...

specific Embodiment 2

[0024] This embodiment is similar in structure to Embodiment 1, refer to Figure 5 , the filter main board 1 is provided with a threaded hole, and the porous plate 2 is provided with a second fastening hole corresponding to the threaded hole, and the fastening screw 33 is screwed in the threaded hole through the second fastening hole and the porous The plate 2 is fastened on the filter main plate 1 . In this embodiment, the support member is fixedly arranged on the perforated plate 2 , and the diameter of the through hole 22 on the perforated plate 2 is 10 mm.

[0025] According to different usage requirements, the perforated plate 2 can also be welded on the filter main board 1 .

[0026] The filter plate of the present invention is simple in structure, and can be modified on the basis of the existing filter plate to reduce waste. After the filter press adopts the filter plate of the present invention, the filter cloth is covered on the porous plate. After passing through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com