Cream production line residue cleaning system

A production line and cream technology, applied in the direction of cream preparations, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of increasing production costs and sewage treatment pressure, raw materials cannot be stored safely, residual cream raw materials, etc., and achieve water cycle control Convenience, good monitorability, avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

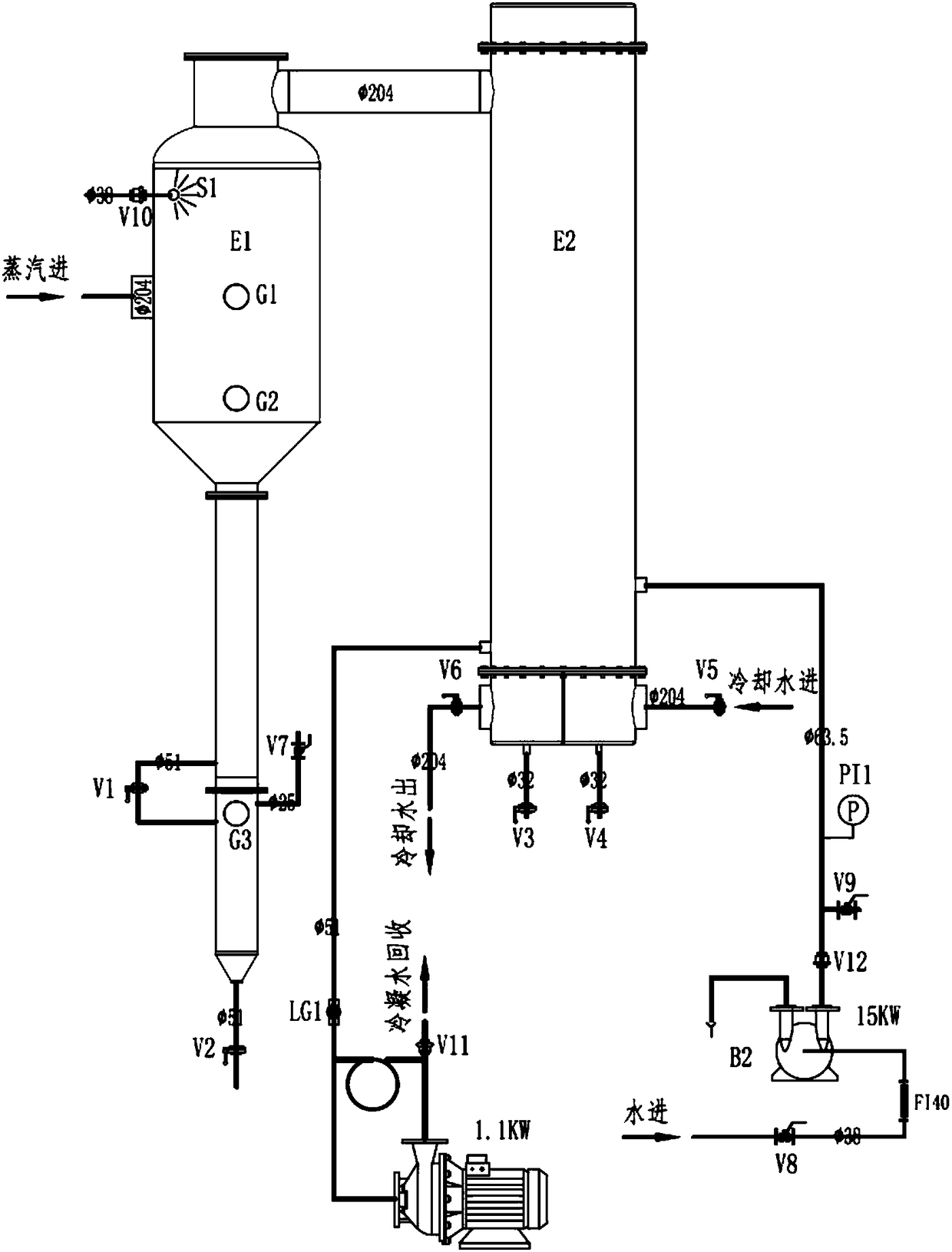

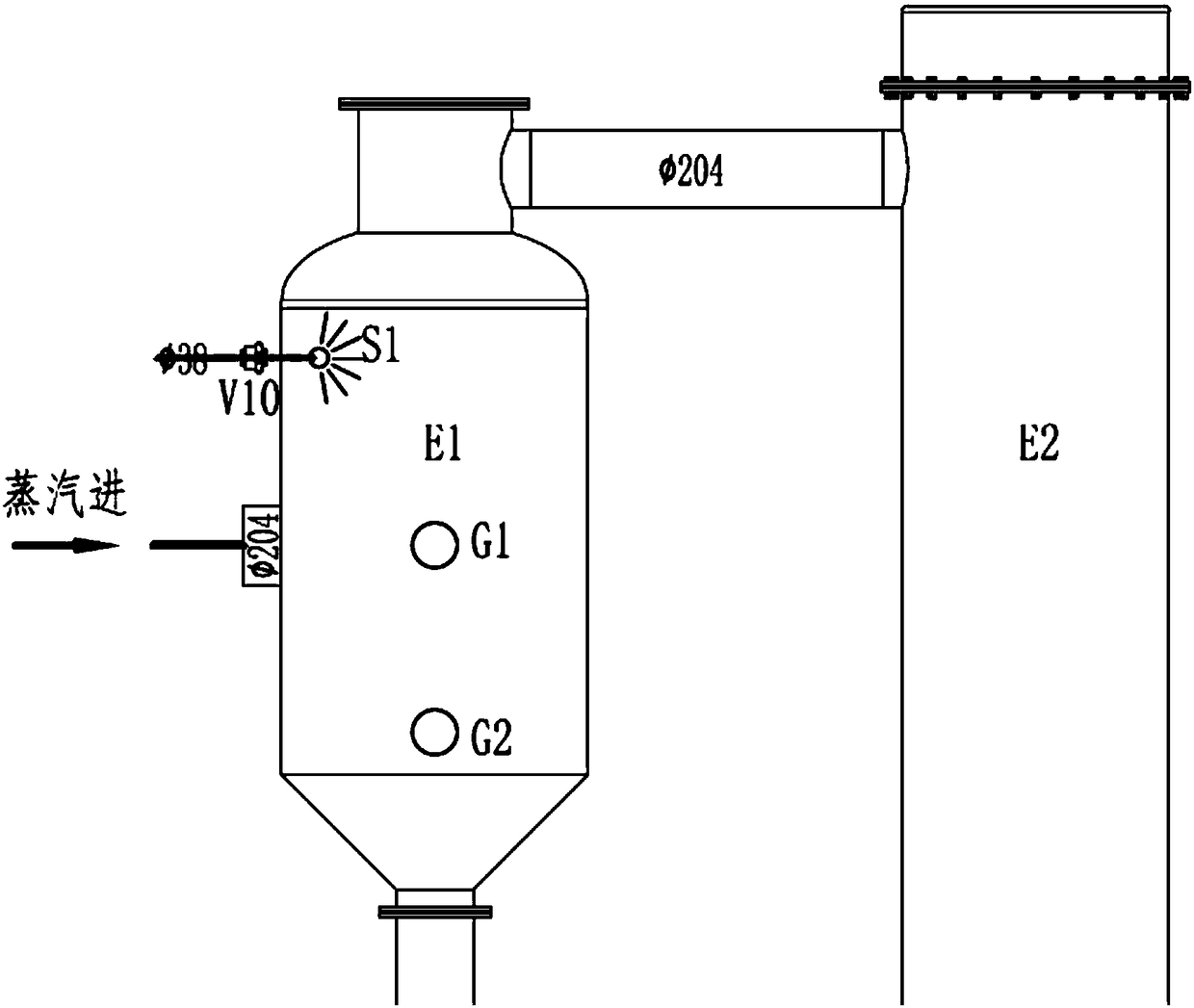

[0027] see Figure 2-Figure 4 , a system for cleaning leftovers in a cream production line, the cream production line includes a batching tank, an aging tank, and a filling machine connected in sequence; a first vacuum system and a second vacuum system are arranged between the batching tank and the aging tank, A third vacuum system is provided between the aging cylinder and the filling machine; each of the three vacuum systems includes a vacuum pump, an auxiliary cylinder E2, and a suction target cylinder E1, and the cylinder mouth between the auxiliary cylinder E2 and the suction target cylinder E1 Through the auxiliary pipeline connection, the cylinder port of the suction target cylinder E1 is also connected with the residual raw material pipeline to be sucked; the vacuum pump is connected with the auxiliary cylinder E2, so that a stable nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com