Machining method for preventing rolled threads of TC4 titanium alloy material from generating folds

A technology of rolling thread and processing method, which is applied in the processing field of avoiding the folding of TC4 titanium alloy material rolling thread, can solve the problems that cannot meet the tensile test and fatigue test, thread overheating, tooth flank cracking, etc., and meet the mechanical Performance test requirements, the effect of avoiding thread folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0027] A processing method for avoiding the folding of TC4 titanium alloy material rolling threads. In order to ensure the thread quality and mechanical performance test requirements of TC4 high-strength titanium alloy bolts, it is necessary to strictly control the bolt thread rolling process and parameters. The method includes the following steps:

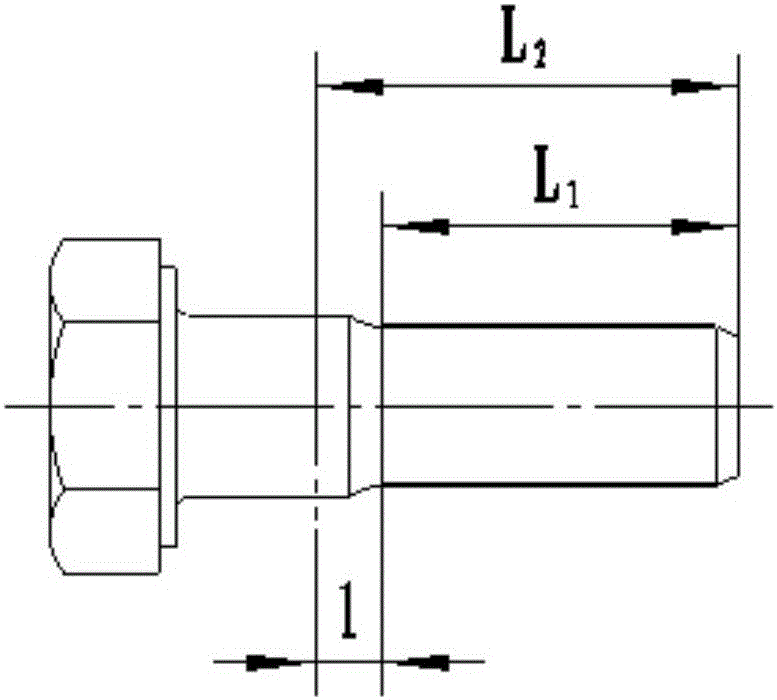

[0028] (1) Pre-preparation; use an optical axis of similar material to the product and have the same blank size as the product as a tool for threading, and install the optical axis on the supporting plate on the thread rolling machine; the length of the optical axis is the length of the rolled thread L 1 3 times of that, the straightness is not greater than 0.01mm, the cylindricity is not greater than 0.005mm, and the taper is not greater than 0.003mm; and the number of optical axes is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com