Novel object drilling equipment

A kind of drilling equipment and object technology, which is applied in the field of new object drilling equipment, can solve the problems of low efficiency, difficult to clean impurities, and prone to errors, etc., and achieve the effect of convenient use and easy removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

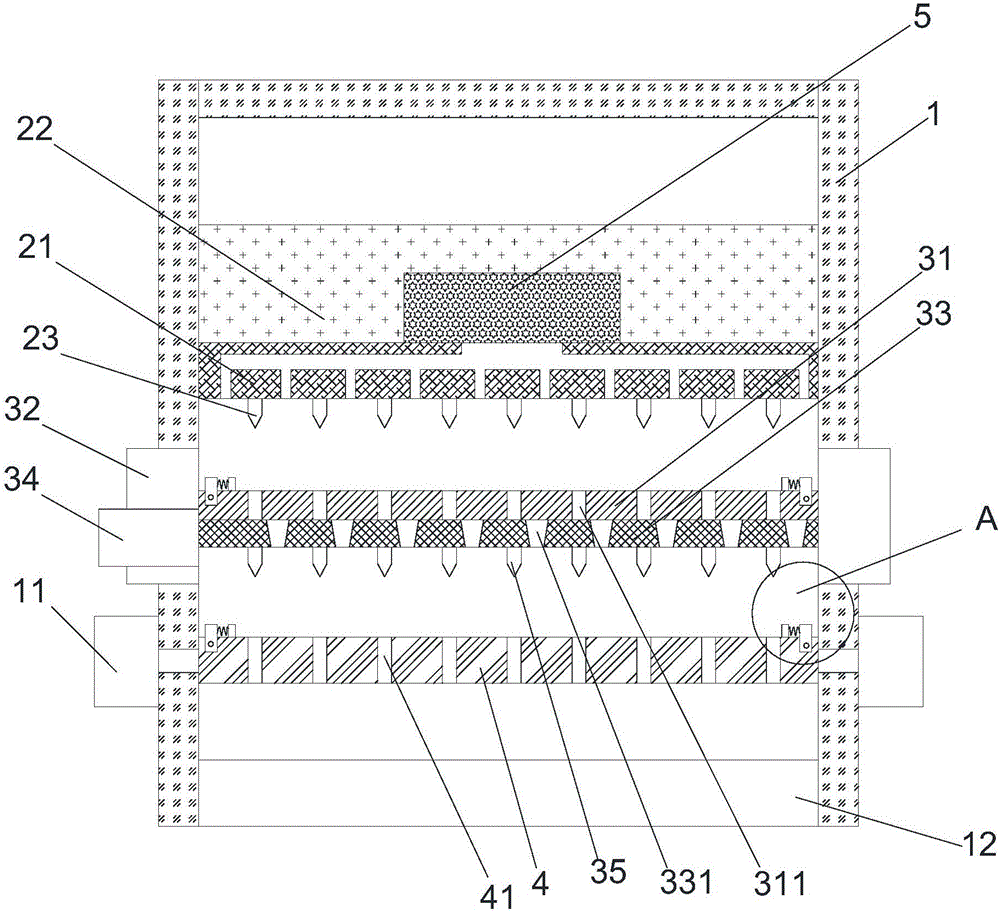

[0017] refer to figure 1 and figure 2 As shown, a novel object drilling equipment proposed by the present invention includes a frame 1, an upper pressing mechanism, a transition mechanism, a bearing plate 4, a blower 5 and a plurality of limit mechanisms.

[0018] The pressing mechanism comprises a first sliding frame 21, a first driving device 22 and a first drill bit group 23. The first sliding frame 21 is movably mounted on the frame 1, and the first driving device 22 drives and connects the first sliding frame 21. A driving device 22 drives the first sliding frame 21 to move vertically. The first drill bit group 23 is installed on the lower end of the first sliding frame 21. The first drill bit group 23 includes a plurality of first drill bits.

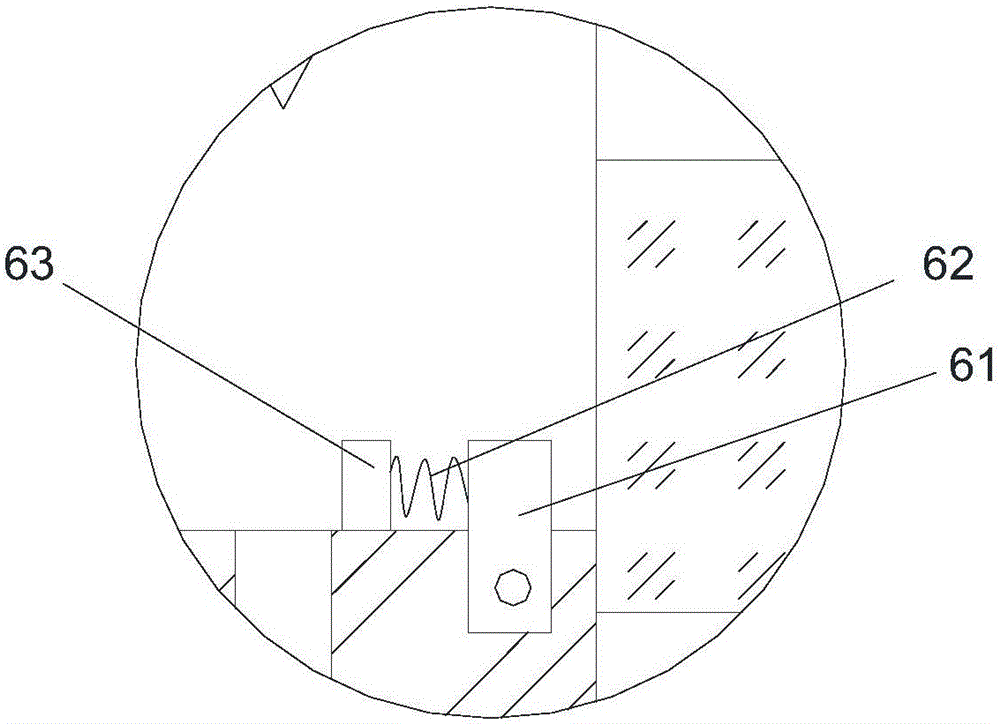

[0019] The transition mechanism includes a forming frame 31, a second driving device 32, a second sliding frame 33, a third driving device 34 and a second drill bit group 35; Below, the second driving device 32 drives and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com