Filling device capable of quantifying liquid-state fertilizer

A filling device and liquid fertilizer technology, which is applied to liquid materials, mixers with rotating stirring devices, packaging, etc., can solve the problem that the filling speed and filling volume cannot be well adjusted, and it is difficult to observe the amount of injected liquid , production personnel inconvenience and other problems, to achieve the effect of good filling effect, simple structure and high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

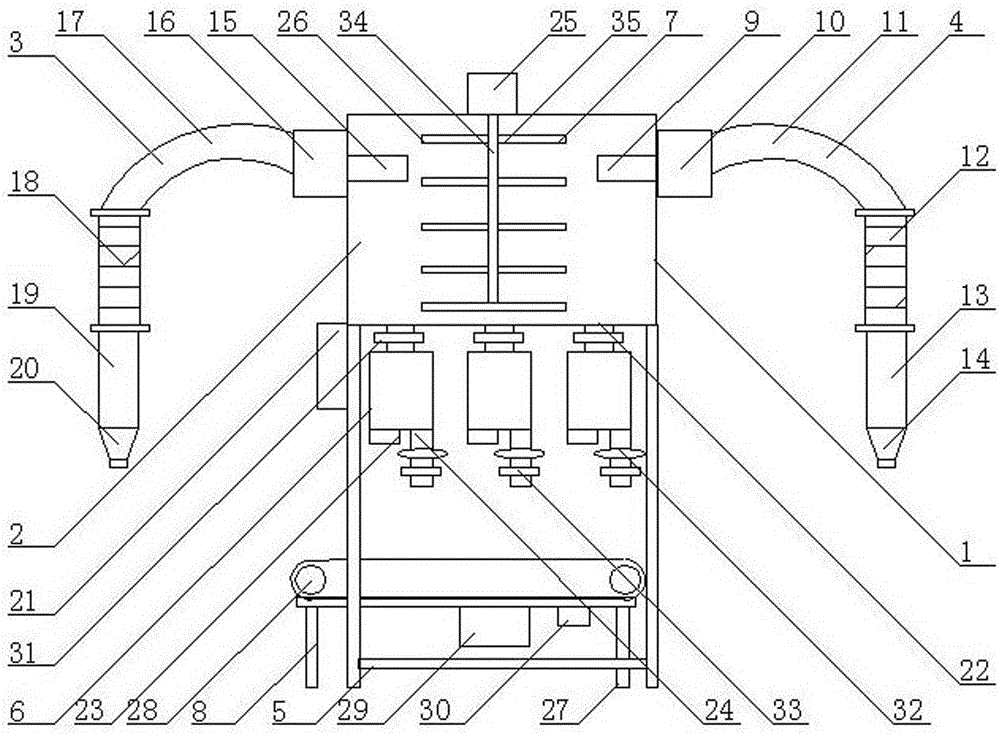

[0021] As shown in the figure, a filling device capable of quantifying liquid fertilizers includes a body 1, a liquid storage tank 2 is installed on the upper end of the body 1, and a first material suction device is installed on the upper ends of the left and right sides of the liquid storage tank 2. 3. The second material suction device 4, the first bracket 5 is installed on the left and right sides of the bottom of the liquid storage tank 2, and three side-by-side dispensing cylinders 6 are installed in the middle of the bottom of the liquid storage tank 2, and the liquid storage tank 2. A mixing device 7 is installed at the middle end of the interior, and a conveying device 8 is installed at the lower end of the dispensing cylinder 6 .

Embodiment 2

[0023] As shown in the figure, the first material suction device 3 is composed of a first liquid inlet pipe 9, a first liquid suction pump 10, a first liquid suction elbow 11, a first telescopic hose 12, and a first liquid suction pipe 13. , the first liquid inlet pipe 9 is installed at the upper left end of the liquid storage tank 2, the first liquid suction pump 10 is installed at the left end of the first liquid inlet pipe 9, and the first liquid suction pump 10 is installed on the left side of the first liquid suction pump 10. The suction elbow 11, the bottom end of the first suction elbow 11 is equipped with a first telescopic hose 12, the bottom end of the first telescopic hose 12 is equipped with a first suction pipe 13, and the first suction pipe 13 The first conical liquid suction nozzle 14 is installed at the bottom end.

Embodiment 3

[0025] As shown in the figure, the second suction device 4 is composed of a second liquid inlet pipe 15, a second liquid suction pump 16, a second liquid suction elbow 17, a second telescopic hose 18, and a second liquid suction pipe 19. , the second liquid inlet pipe 15 is installed at the upper right end of the liquid storage tank 2, the second liquid suction pump 16 is installed at the right end of the second liquid inlet pipe 15, and the second liquid suction pump 16 is installed on the right side of the second liquid inlet pipe. The suction elbow 17, the bottom end of the second suction elbow 17 is equipped with a second telescopic hose 18, the bottom end of the second telescopic hose 18 is equipped with a second suction pipe 19, the second suction pipe 19 second conical liquid suction nozzles 20 of the bottom device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com