Improved dual-precision electronic scale

A double-precision, electronic scale technology, applied in special scales, measuring devices, instruments, etc., can solve the problems of use, high price, and cannot be used for other purposes, and achieve the effects of preventing damage, easy to popularize, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

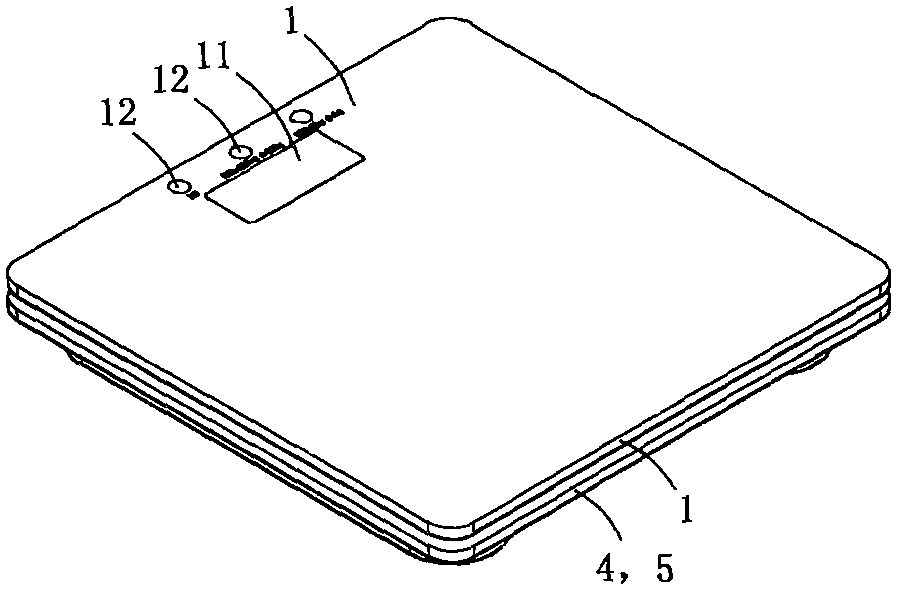

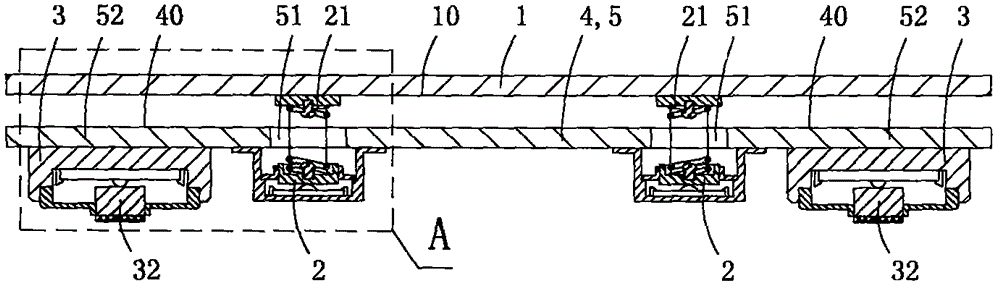

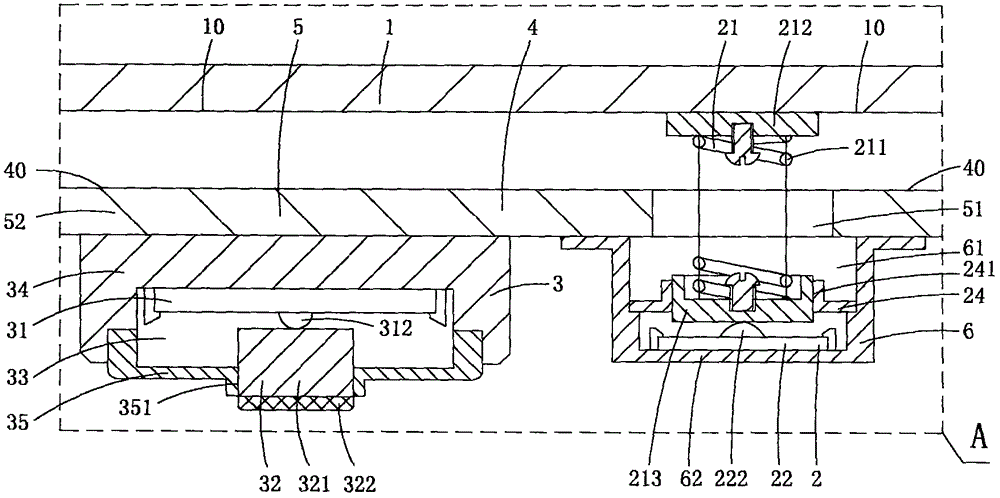

[0015] This embodiment is an improved double-precision electronic scale, see Figure 1 to Figure 8 As shown, it includes an object carrier 1, a display screen 11, an adjustment switch 12, four first-precision weighing components for supporting the object carrier 2, and four first-precision weighing components for supporting the object carrier and The second-precision weighing assembly 3, and four force guides 4 for transmitting the pressure it receives to the second-precision weighing assembly.

[0016] The guiding member 4 in this embodiment includes a bearing plate 5 provided with a supporting hole 51 and a crimping plate area 52, and four mounting members 6 fixed on the bottom wall of the bearing plate; each mounting member 6 has a corresponding one corresponding to each other. The supporting hole 51 is provided with a placement cavity 61; the bottom wall 62 of the placement cavity is provided with a clamping groove, and the placement cavity is also provided with a horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com