Movable multifunctional train test platform with movable model

A test platform and dynamic model technology, which is applied in the direction of railway vehicle testing, etc., can solve the problems of not simulating the running situation of the dynamic model and the actual simulation of the running situation of the train.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention.

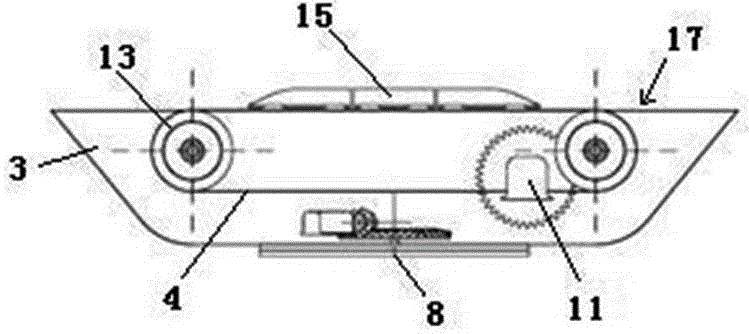

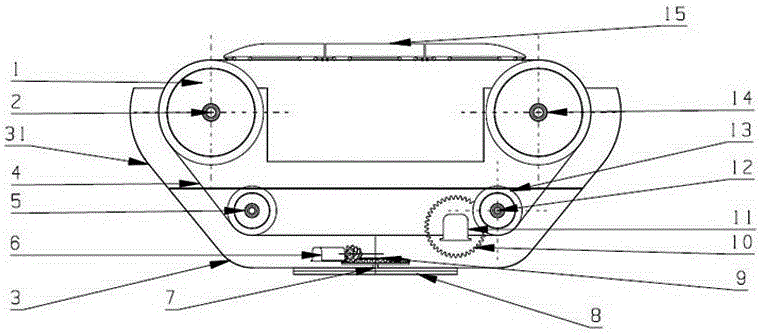

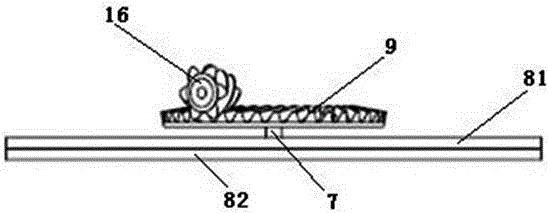

[0033] Such as Figure 1-8 The shown mobile multifunctional dynamic model train test platform includes a shell 3, a pulley 13, a belt 4, a chassis 8 and a train model 15.

[0034] The two pulleys 13 are mounted on the housing 3 through the first rotating shaft 12 and the bearing 5. The belt 4 is connected to the two pulleys 13, the belt 4 bypasses the two pulleys 13 and the upper half of the belt 4 is arranged horizontally, the first motor 11 and the pulley 13 is connected to and drives the pulley 13 to rotate. The two pulleys 13 are installed inside the casing 3, and the top ends of the pulleys 13 extend from the top surface of the casing 3. The first rotating shafts 12 of the two pulleys 13 are parallel to each other,

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com