Method for determining optimum water content and maximum dry density of cement-stabilized macadam

A cement-stabilized gravel and optimal water content technology, which is applied in the field of transportation civil engineering, can solve the problems of heavy workload and long test period, and achieve the effect of reducing workload, shortening test period and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

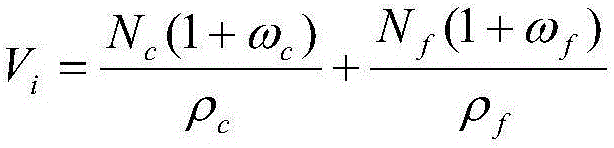

[0046] A method for determining optimum water content and maximum dry density of cement-stabilized crushed stone, comprising the following steps:

[0047] A. According to the design gradation, determine the weight percentage N of the aggregate on the sieve with a sieve diameter of 4.75mm c , the weight percentage N of the aggregate under the sieve f ;

[0048] B. Carry out the compaction test of cement-stabilized macadam under the cement dosage a, and obtain the maximum dry density ρ a , corresponding to the optimal water content ω a ;

[0049] C. Determination of the surface dry density ρ of the sieve aggregate (coarse aggregate) with a sieve diameter of 4.75mm c and water absorption ω c ;

[0050] D. Determination of the surface dry density ρ of the under-sieve aggregate (fine aggregate) with a sieve diameter of 4.75mm f and saturated surface dry water absorption ω f ;

[0051] E. Determination of cement density ρ cr ;

[0052] F. Mix the above-sieve aggregate wit...

Embodiment 2

[0102] A method for determining the optimal water content and maximum dry density of cement-stabilized crushed stone. The difference from Example 1 is that in this example, the cement dosage is calculated by the method of the present invention on the basis that the cement dosage a is 3%. The optimum water content and maximum dry density are 5%.

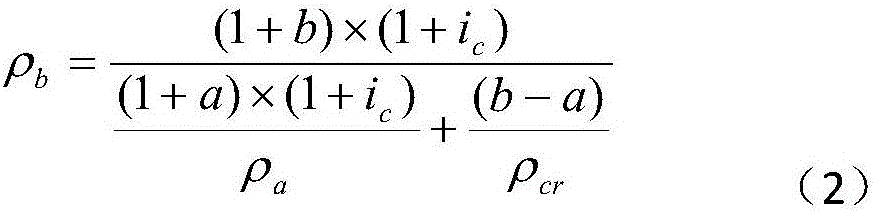

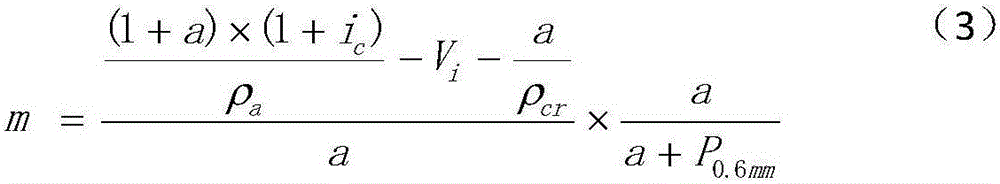

[0103] When implementing step H, the cement dosage b is 5% into the formula (1), and when the calculated cement dosage is 5%, the optimal water content is 4.5%; the relevant parameters are brought into the formula (2), and the calculated cement When the dosage is 5%, the maximum dry density is 2.37g / cm 3 .

[0104] According to the compaction test, when the cement dosage b is 5%, the optimum water content is 4.4%, and the maximum dry density is 2.37g / cm 3 .

[0105] Visible, adopt the method of the present invention, when cement dose is 5%, the maximum dry density that calculates and optimum water content result and compaction test...

Embodiment 3

[0107] A method for determining the optimal water content and maximum dry density of cement-stabilized crushed stone. The difference from Example 1 is that in this example, the cement dosage is calculated by the method of the present invention on the basis that the cement dosage a is 3%. The optimum water content and maximum dry density are at 6%.

[0108] When implementing step H, the cement dosage b is 6% into the formula (1), and when the calculated cement dosage is 5%, the optimal water content is 4.7%; the relevant parameters are brought into the formula (2), and the calculated cement When the dosage is 5%, the maximum dry density is 2.37g / cm 3 .

[0109] According to the compaction test, when the cement dosage b is 6%, the optimum water content is 4.5%, and the maximum dry density is 2.38g / cm 3 .

[0110] Visible, adopt the method of the present invention, when cement dose is 6%, the maximum dry density that calculates and optimum water content result and compaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com