Axis deviation detection device for beam sensor

A technology for detecting device and axis offset, which is applied in the direction of measuring device, instrument, and re-radiation, and can solve the problems of axis offset detection of difficult laser beam sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following embodiments of the present disclosure and appended Figure 1 to explain.

[0043] First, a first embodiment of the present disclosure will be described.

[0044] [1. Explanation of the structure of the driving assistance system 1]

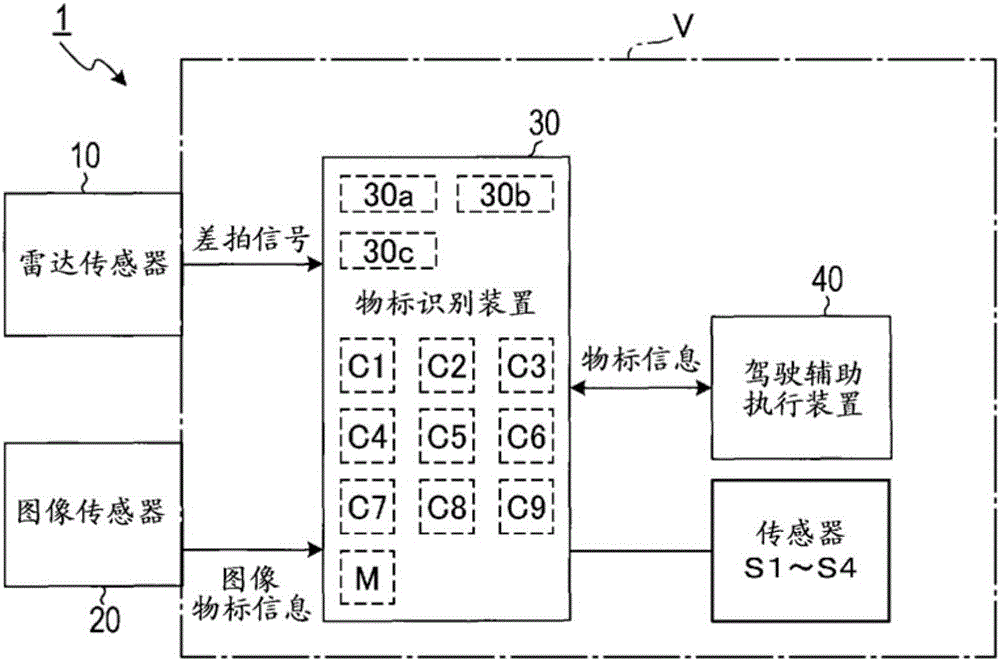

[0045] The driving assistance system 1 according to the first embodiment is composed of a radar sensor 10 , an image sensor 20 , an object marker recognition device 30 , and a driving assistance execution device 40 , and is mounted on a vehicle V. As shown in FIG.

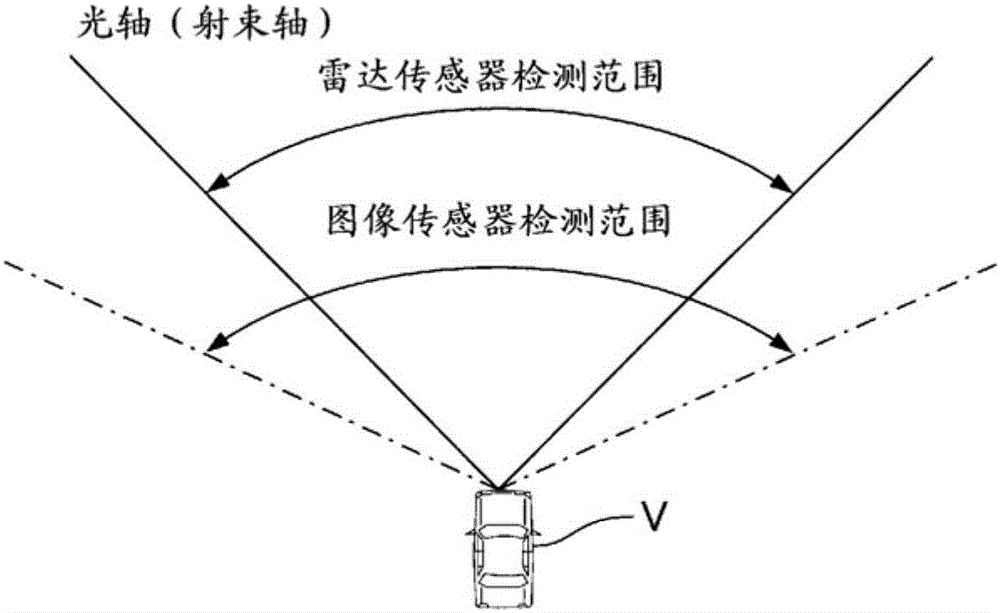

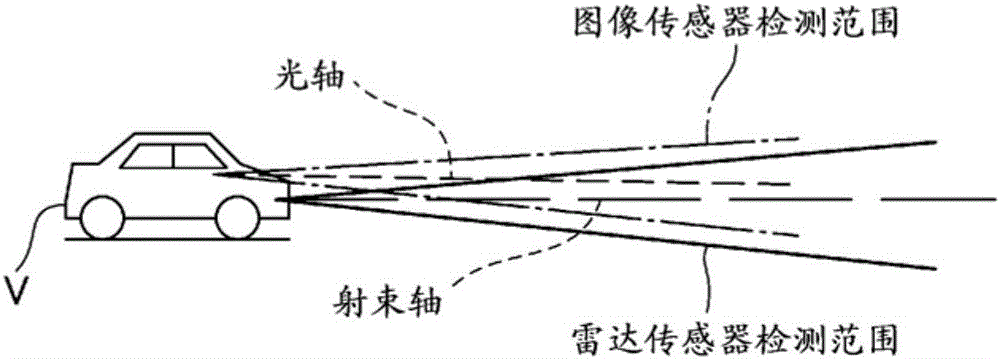

[0046]The object marker recognition device 30 is connected so as to be able to communicate with each of the radar sensor 10 , the image sensor 20 , and the driving assistance execution device 40 . The radar sensor 10 irradiates radar waves (radar beams) toward a first detection area (first detection range) set in front of the host vehicle, and receives the reflected waves (reflection beams). In addition, the image sensor 20 images a second detection area set in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com