Extrusion mold for artificial marble composite decoration door frame architrave sectional material

A technology of imitating marble and extruding molds, which is applied in the field of extrusion molds for imitating marble composite decorative door frame sleeve profiles, can solve the problems of multi-bubble, round hole deformation, influence on strength and rigidity, etc., and achieves long service life and round hole deformation. Small, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

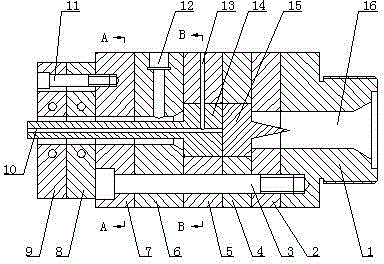

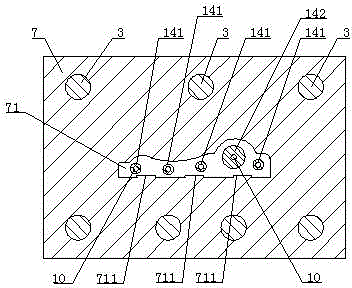

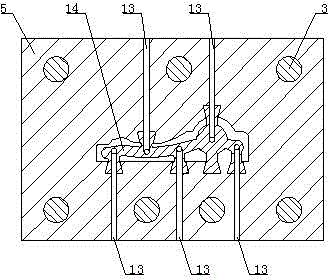

[0009] see Figure 1 to Figure 3 , the present invention includes a mold body 1, a transition plate 2, a support plate 4, a support plate 2 5, a manifold 6, a mouth template 7, a water jacket 8, a water jacket 2 9, a rear mandrel group 14, and a front mandrel 15 , several long screws 3 and several short screws 11, the right side of the mold body 1 is provided with a main material feed port 16, and the rear mandrel group 14 includes a large round mandrel 142 and four small round mandrels Rod 141, and an axial ventilation hole 10 is respectively provided at the middle position of the large round mandrel 142 and four small round mandrels 141, and the middle position of the mouth template 7 is provided with a die hole 71, And three rectangular protrusions 711 are provided on the bottom surface of the die hole 71, and a co-extrusion feed inlet 12 is provided on the manifold 6, between the bracket plate 2 5 and the rear mandrel group 14 And corresponding to the position of each axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com