Sheeting assembled container

An assembled and containerized technology, applied in the structural field of general cargo containers, can solve the problems of difficulty in automation, high cost of empty container delivery, and difficulty in transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

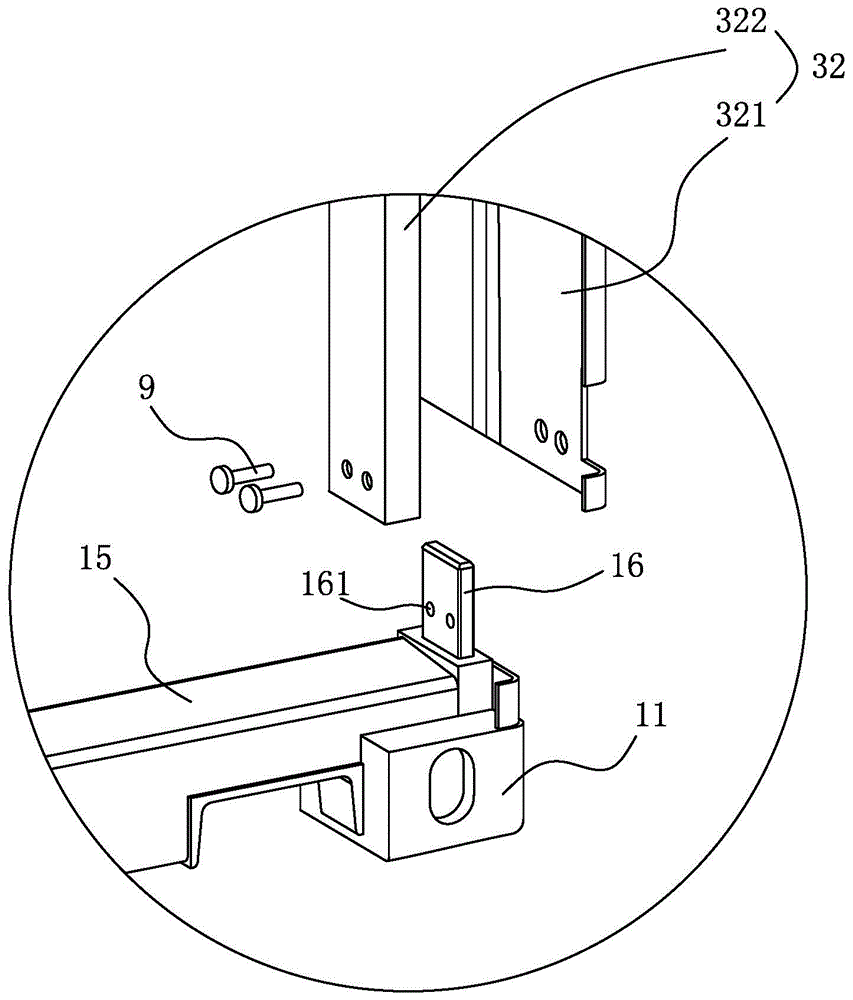

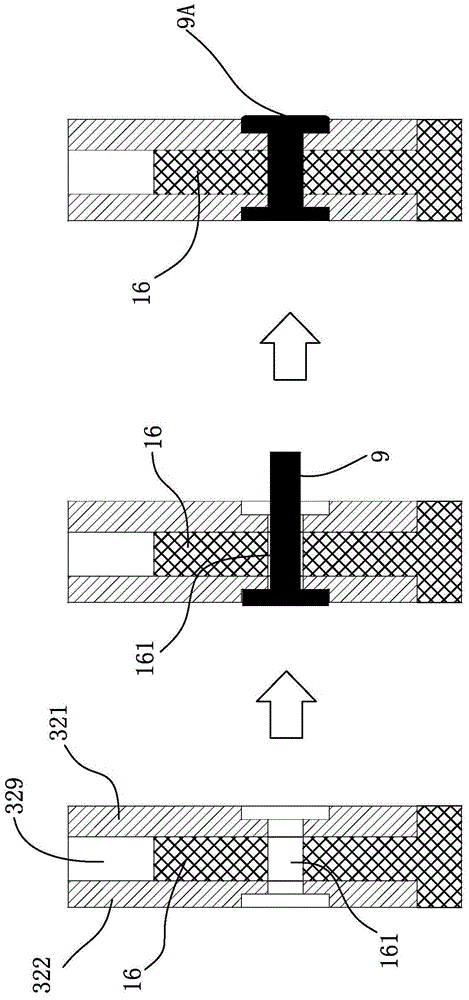

[0051] The present invention will be further elaborated below with reference to the drawings.

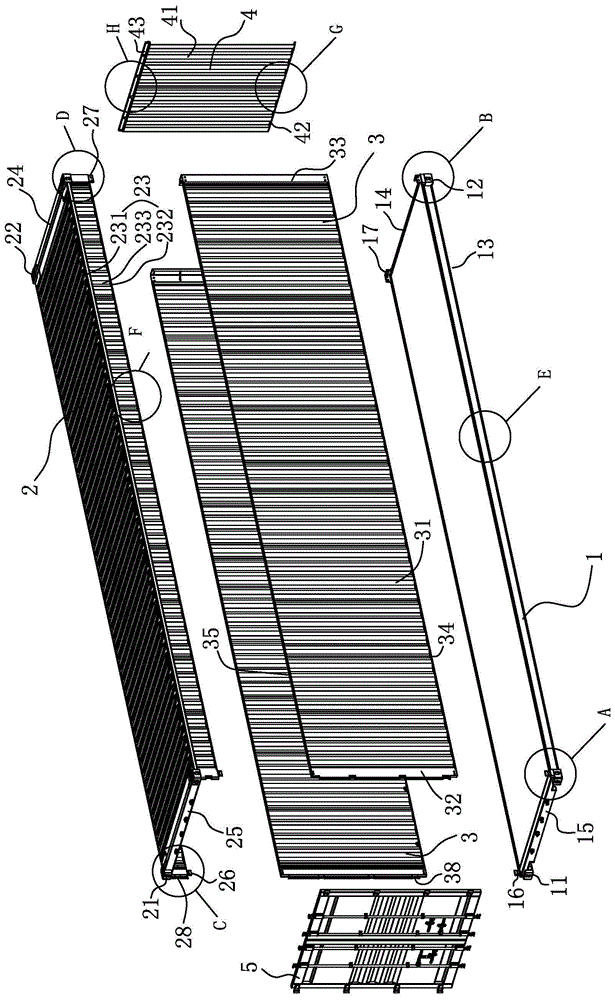

[0052] See Figure 1 to Figure 10 , The present invention proposes a preferred embodiment of the slicing assembled container is composed of a bottom finished module 1, a top finished module 2, two side finished modules 3, a front finished module 4, and a door finished module 5. A general cargo container conforming to ISO standards.

[0053] See Picture 10 Before being assembled into a container, these finished modules 1, 2, 3, 4, and 5 can be combined into a stacking and transportation assembly 10; then, multiple stacking and transportation assemblies 10 can be stacked together for storage and transportation; and finally , Complete the assembly of the container at a location close to the customer. The split-assembled container of the present invention can greatly reduce the costs of storing and transporting newly manufactured empty containers before they are delivered to customers.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com