Composite exhaust vent muffler

A muffler and sound absorption technology, applied in the direction of pipes/pipe joints/fittings, general water supply saving, mechanical equipment, etc., to achieve the effect of eliminating high noise, convenient installation, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

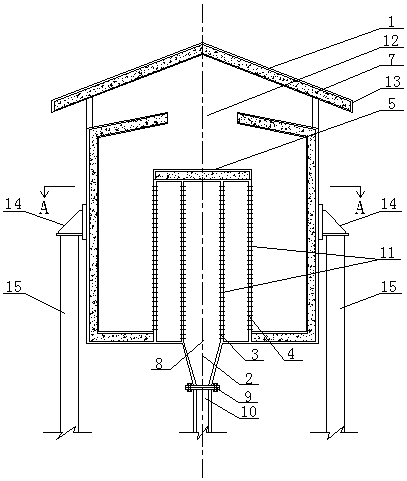

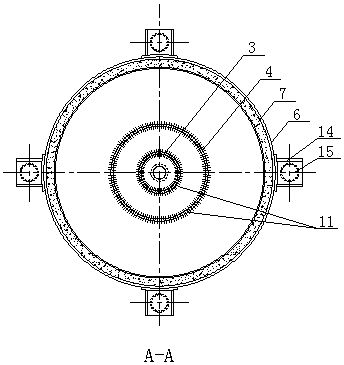

[0026] exist figure 1 , 2 In the shown embodiment, a composite exhaust and venting muffler is composed of a rainproof sound-absorbing umbrella cap (1), an expansion gradient tube (2), a first-stage throttling and pressure-reducing tube (3), a second-stage throttling and pressure-reducing tube (4), the top plate of the throttling and pressure-reducing tube (5), the muffler cylinder (6), the resistive sound-absorbing layer (7), and the installation load-bearing structure. The bottom port (8) of the expansion gradient tube (2) is connected to the top (10) of the vent tube through the flange (9), and the upper port (8) is connected to the first-stage throttle step-down tube (3), and the expansion gradient The area of the upper port (8) of the tube (2) is ≥ twice the area of the bottom port (8), and the wall slope of the expansion gradient tube (2) is 6-10º; the first-stage throttling and step-down tube (3) The pipe wall is provided with a first-stage injection hole (11), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com