Horizontal breaking machine

A horizontal and frame technology, applied in the field of horizontal breaking machines, can solve the problems of glass surface scratches and broken section quality, reduce the flatness of glass broken sections, affect the working environment, etc., and achieve a wide range of glass thickness and power The transmission system is stable and reliable, and the effect of eliminating high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

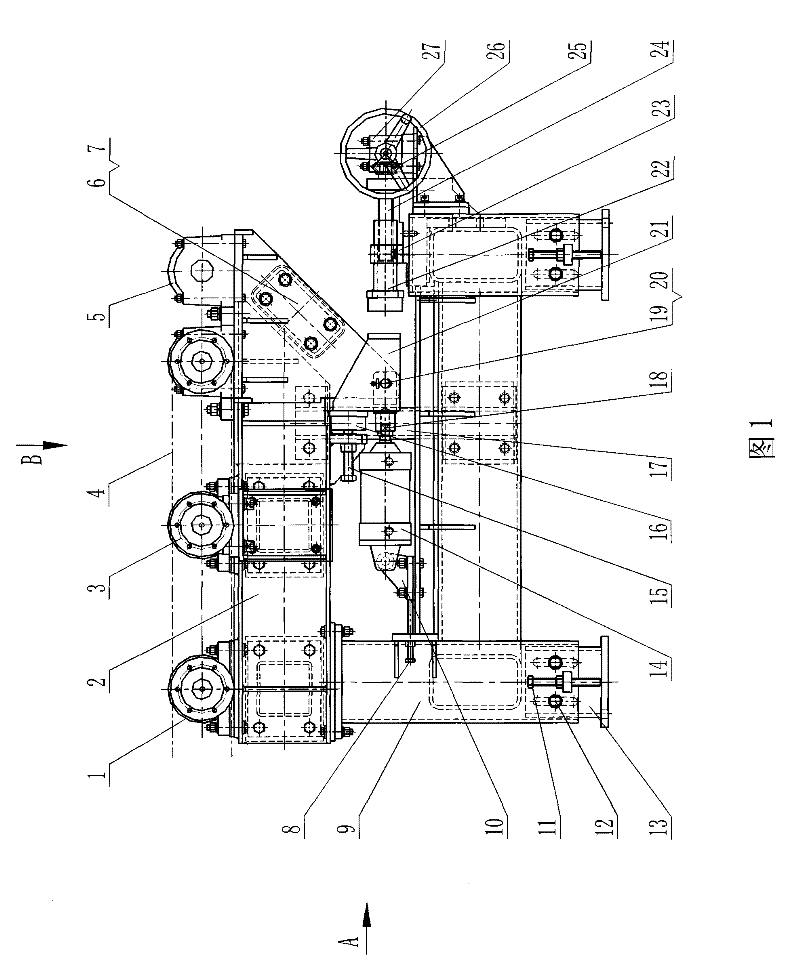

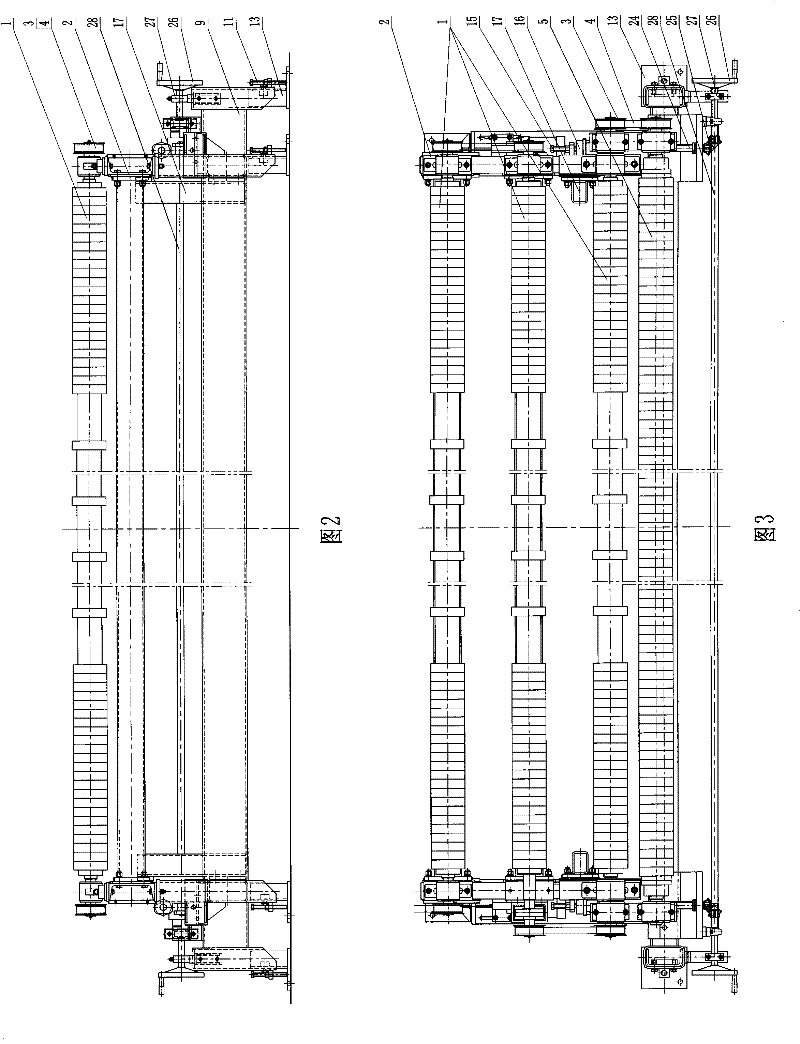

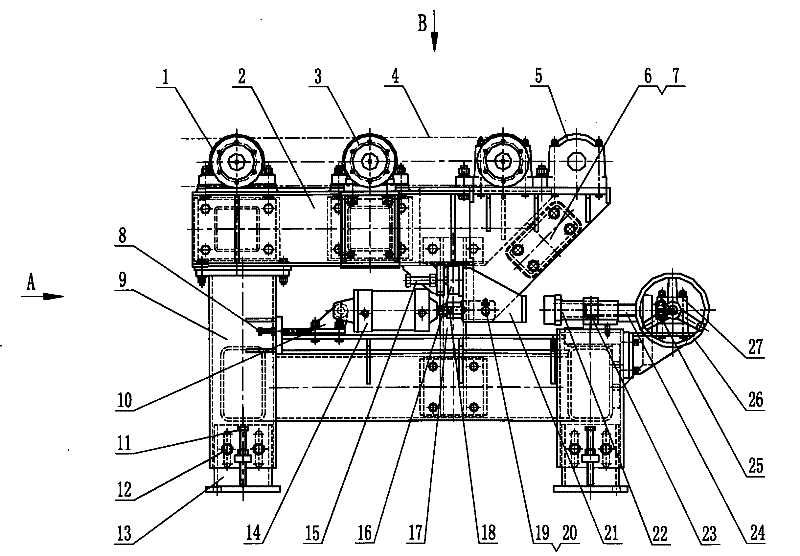

[0014] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0015] Such as figure 1 , 2 , shown in 3: it includes longitudinal beams 2 parallel to both sides of the glass advancing direction, three synchronous transmission rollers 1 for conveying glass are arranged on the longitudinal beams 2, and breaking rollers synchronized with the transmission rollers 1 are arranged at the rear end of the transmission rollers 1 5. There are synchronous pulley 3 and synchronous belt 4 for transmitting motion and power on the roller. One end of the longitudinal beam 2 is fixed on the frame 9, and the other end is fixed on the column 17. A cylinder 14 is respectively arranged on the lower frame 9 of the longitudinal beam 2 on both sides. The piston rod of the cylinder 14 is connected with the connecting plate 6 through the fork rod 18, the connection box 21 and the pin shaft 19, and the cotter pin 20 connects the connection box 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com