Memory element and manufacturing method thereof

A memory element and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems affecting the storage capacity and process yield of vertical-channel three-dimensional NAND flash memory components, memory cell defects, affecting components storage capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

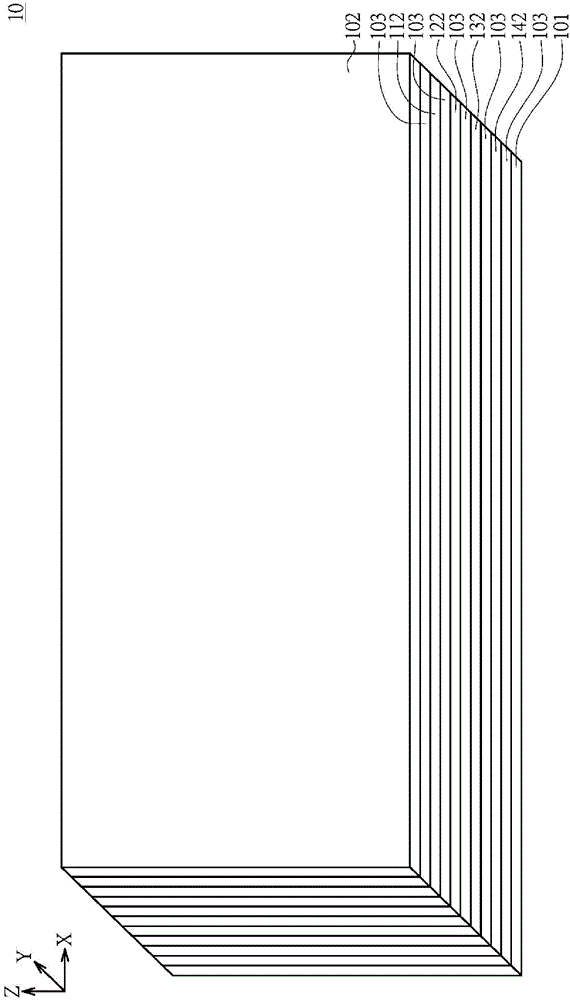

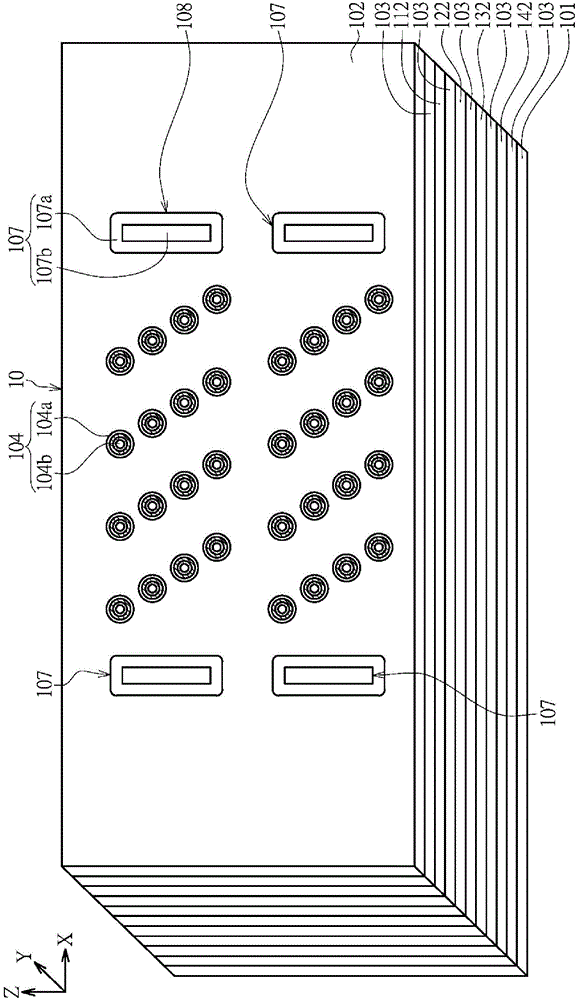

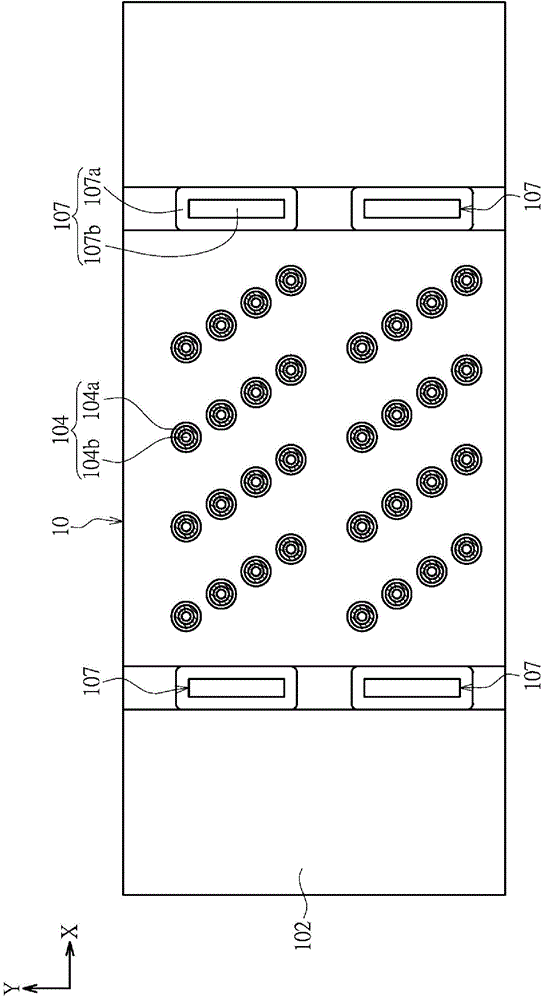

[0047] The present invention provides a memory element and a manufacturing method thereof, which can reduce the overall resistivity of the memory element to reduce signal transmission delay caused by resistance and capacitance. In order to make the above-mentioned embodiments and other objectives, features and advantages of the present invention more comprehensible, a vertical channel type three-dimensional NAND flash memory device 100 is specifically cited below as a preferred embodiment, and will be described in detail with the accompanying drawings.

[0048] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The present invention can still be implemented using other features, elements, methods and parameters. The preferred embodiments are only used to illustrate the technical features of the present invention, and not to limit the scope of the claims of the present invention. Those with ordinary know...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap