New high-dump pitchforks for quick change

A high unloading and pitchfork technology, applied in agriculture, application, agricultural machinery and implements, etc., can solve the problems of smaller use range of unloading devices, large lifting weight, low work efficiency, etc., and achieve fast and powerful unloading action. , The effect of large material capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

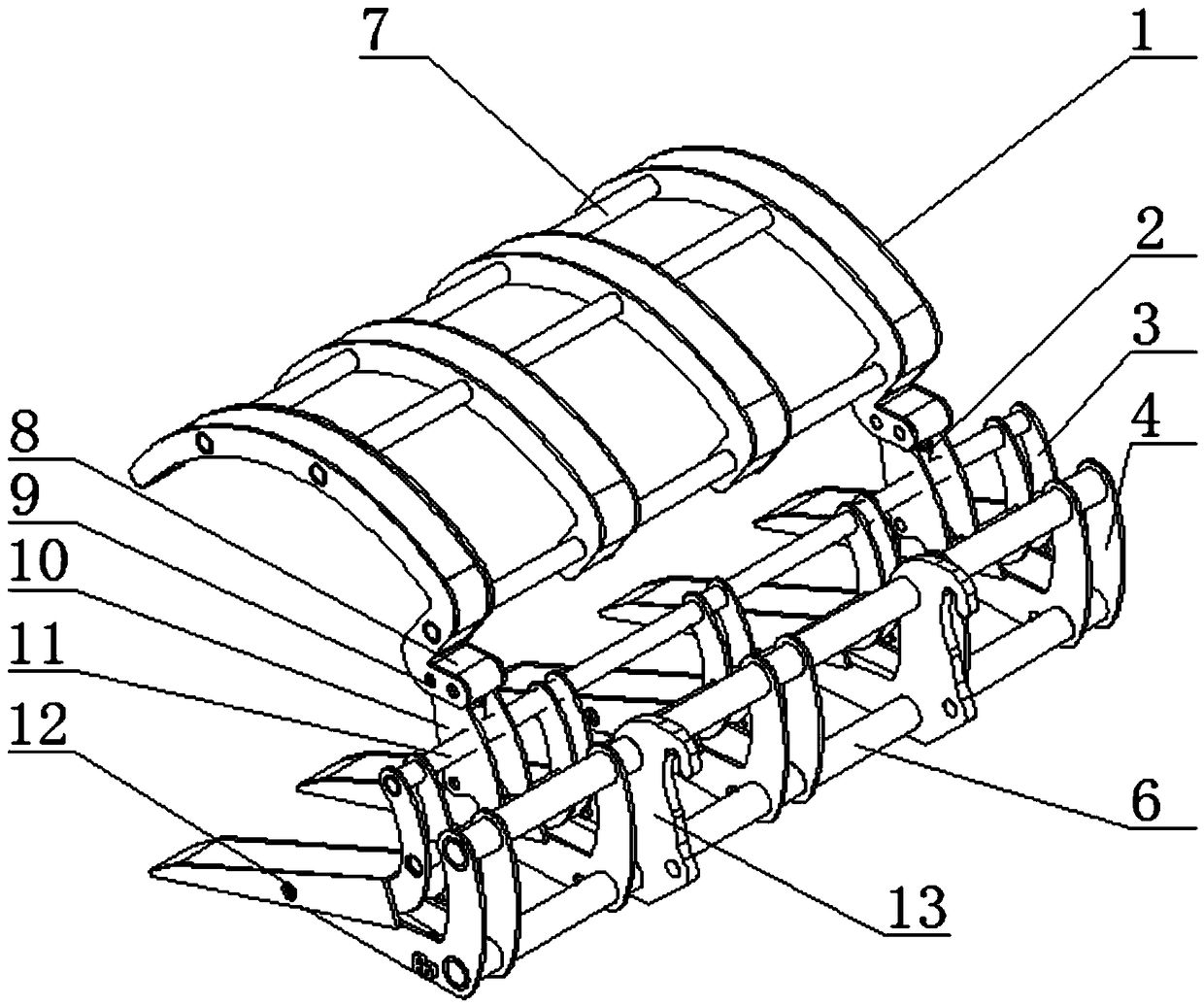

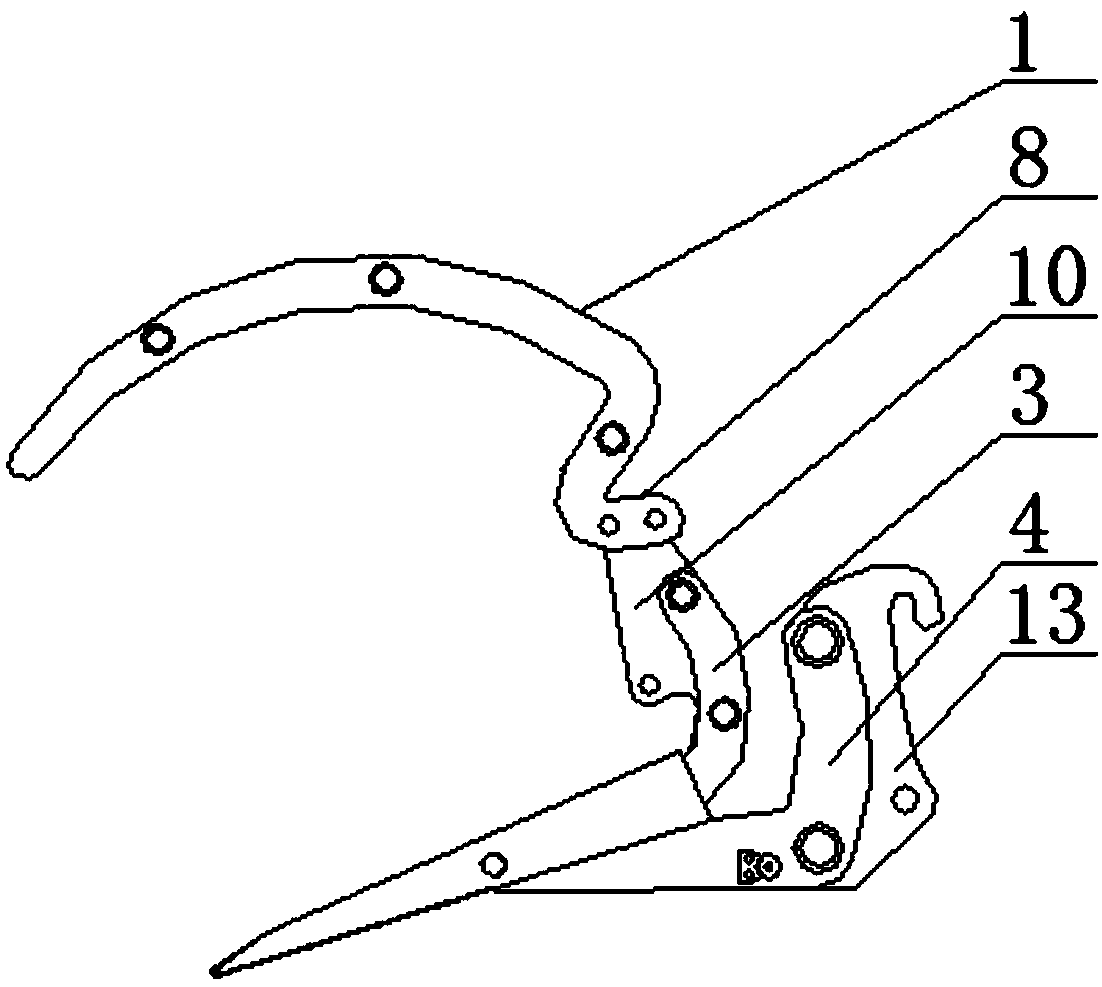

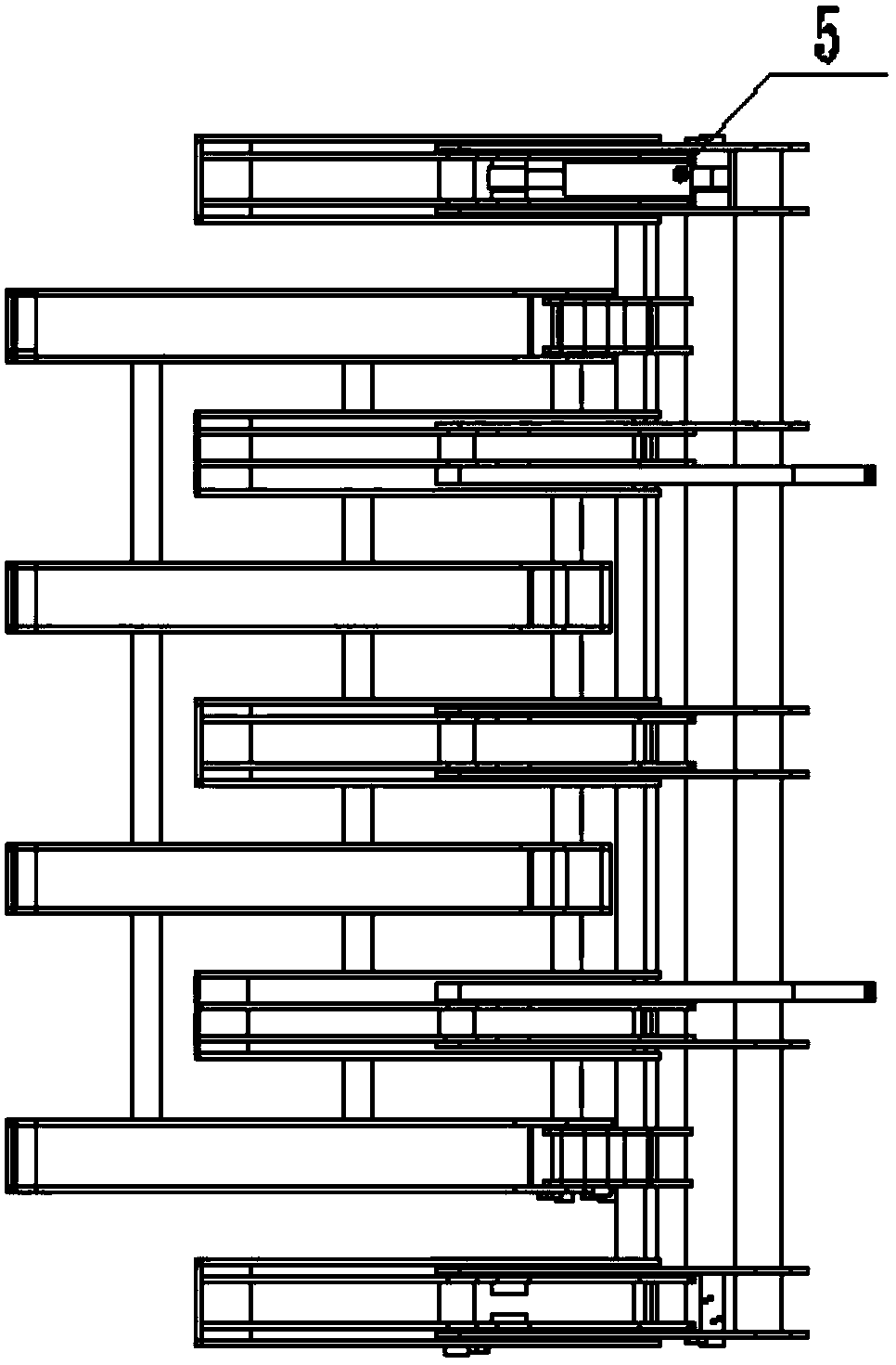

[0023] Such as Figure 1 to Figure 3 As shown, the new high-discharge pitchforks that are quickly replaced, the high-discharge pitchforks I 1, the high-discharge pitchforks II 3 and the high-discharge pitchforks III 4 are all made of criss-cross ribs, and the high-discharge pitchforks I 1 are respectively It is oppositely arranged with the high-discharge pitchfork II 3 and the high-discharge pitchfork III 4, and the high-discharge pitchfork I 1 is connected with the high-discharge oil cylinder I 2 below, and the high-discharge pitchfork I 1 passes through the pin shaft I 9 and the high-discharge pitchfork II 3 Connection, the middle part of the fork body of the high-discharge pitchfork II 3 and the fork body end of the high-discharge pitchfork III 4 are hinged through the pin II 12, and the high-discharge pitchfork II 3 and the high-discharge pitchfork III 4 are mutually along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com