Electronic cigarette atomizer using vertical ceramic atomizing units

An electronic cigarette atomizer, vertical technology, applied in the field of electronic cigarettes, can solve problems such as bad smoking experience, deformation of atomizing rods, reducing atomization effect, etc., so as to improve smoking taste, ensure atomization effect, and avoid burning smell. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

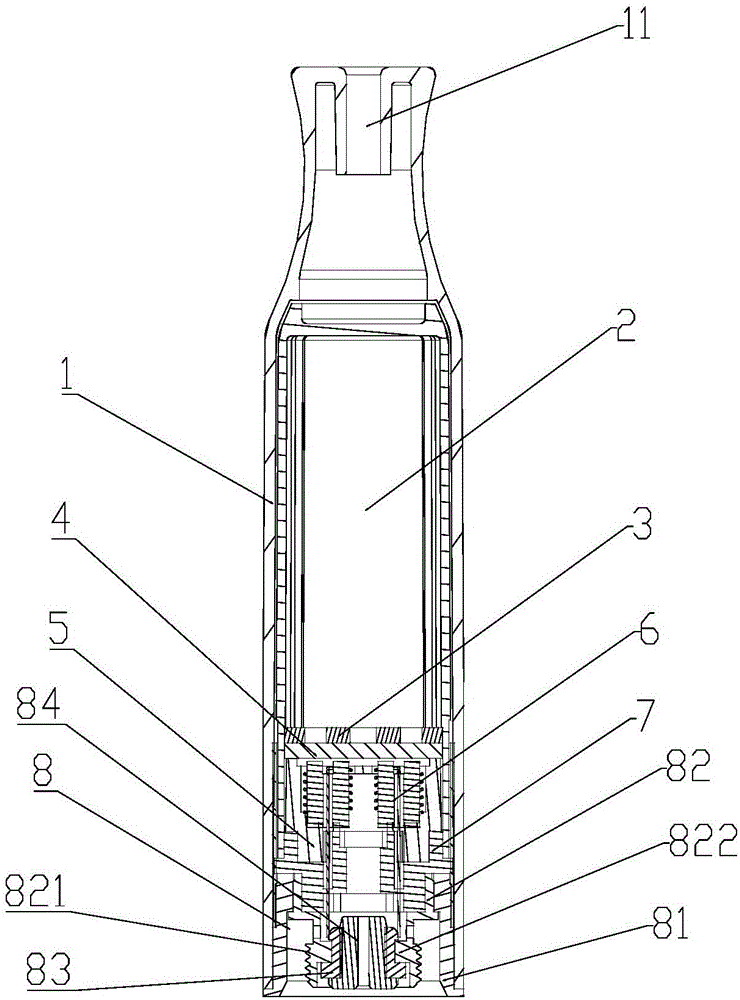

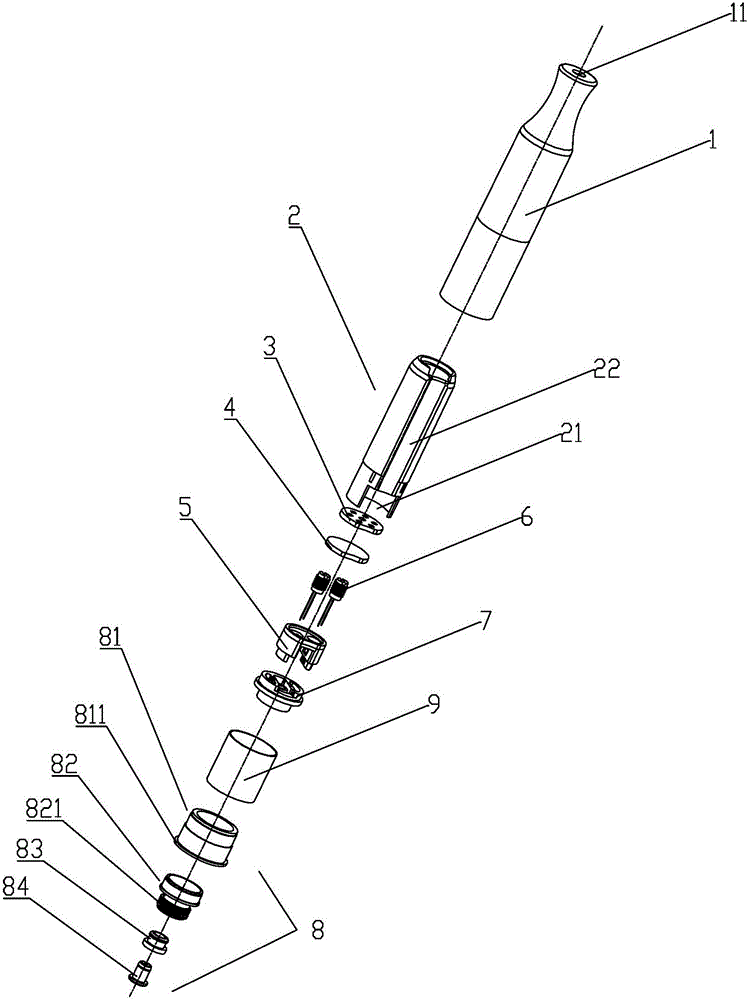

[0033] Such as figure 1 , figure 2 As shown, the present invention uses an upright ceramic atomization unit for an electronic cigarette atomizer, which includes an outer tube 1 with a suction hole 11 at the upper end and an open lower end, a liquid storage cup 2 that is set in the outer tube 1 from top to bottom in sequence, Porous supporting sheet 3 , e-liquid penetration sheet 4 , atomization seat 5 , atomization unit 6 , sealing connection seat 7 , power supply connection seat 8 . The liquid storage cup 2 is used for storing e-cigarette liquid. The porous support sheet 3 is fixed horizontally on the inner wall of the lower end of the liquid storage cup 2, and the porous support sheet 3 is plugged into the opening of the liquid storage cup 2, and there are several small holes on it to allow the e-cigarette liquid to flow out slowly from the liquid storage cup 2. The sheet 3 also acts as a fixed support for the e-liquid penetration sheet 4 . The e-liquid penetration sheet...

Embodiment 2

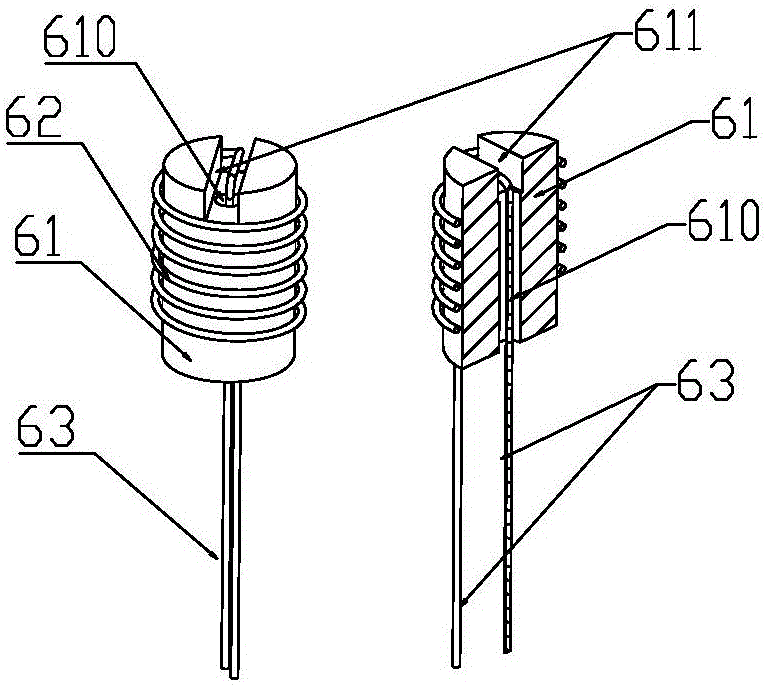

[0041] On the basis of the first embodiment above, the atomization unit 6 is modified, the heating wire 62 is changed from being wound on the outer wall of the ceramic atomizing rod 61 to being arranged inside the ceramic atomizing rod 61, and the rest of the structure remains unchanged.

[0042] Such as Figure 4 As shown, the ceramic atomizing rod 61 is a cylinder, and an atomizing rod through hole 610 is provided on its central axis, and a groove 611 is provided along the diameter on its upper end surface, and the heating wire 62 is wound around the ceramic atomizing rod 61 The inside is integrated with it, and the lead wire 63 of the heating wire 62 is exposed to the atomizing rod 61 and drawn out downwards. The aforementioned atomizing rod through hole 610 and groove 611 are not used for threading the wire 63 , but are used for ventilation and circulation of e-liquid, so that the e-cigarette liquid can penetrate into the ceramic atomizing rod 61 more easily.

Embodiment 3

[0044] On the basis of the first embodiment above, the atomization seat is modified, the two supporting vertical slots are increased to three, and the atomization unit is increased accordingly. The third embodiment designed in this way can further increase the The amount of smoke generated by atomization effectively improves the atomization effect.

[0045] Such as Figure 12-Figure 14 As shown, the upper end of the atomization seat 5 is respectively provided with a support vertical groove 52 on both sides of the smoke outlet 51 and the opposite inner wall, so that there are three support vertical grooves 52, and each support vertical groove 52 is equipped with a mist atomizing unit 6, so that there are three atomizing units 6, and the heating wire 62 of the three atomizing units 6 in the third embodiment is electrically connected to the power supply in parallel connection, so when the atomizer in the third embodiment works At the same time, the amount of smoke generated by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com