Centralized control type electric heating pot

A technology of centralized control and centralized controller, which is applied in the direction of utensils with integral electric heating devices, heating devices, cooking utensils, etc., can solve the problems of inability to seal and waterproof, scattered connection lines, and easy to leak electricity, etc., and achieves convenient installation. , centralized control is convenient, the effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

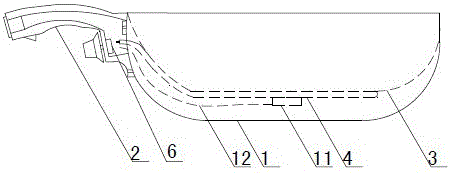

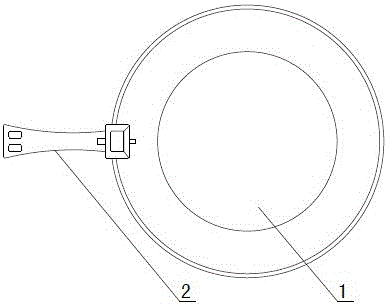

[0065] Figure 1~2 As shown, a centralized control type electric heating pot includes a pot body composed of an inner pot body 3 and an outer pot body 1. The outer pot body 1 is wrapped and fixed at the bottom of the inner pot body 3. In this embodiment, the outer pot body 1 adopts The fully wrapped structure, that is, the upper edge circumference of the outer pot body 1 and the upper edge circumference of the inner pot body 3 are flush and fixed. The outer pot body 1 forms the shell of the centralized control type electric heating pot, the upper surface of the inner pot body 3 is the cooking surface of the centralized control type electric heating pot, and the heating plate 4 is fixed on the lower surface of the inner pot body 3, and the heating plate 4 Located between the outer pot body 1 and the inner pot body 3, the heating plate 4 heats the inner pot body 3 after being energized.

[0066] A control handle 2 is fixed on one side of the outer pot body 1, and a control elem...

Embodiment 2

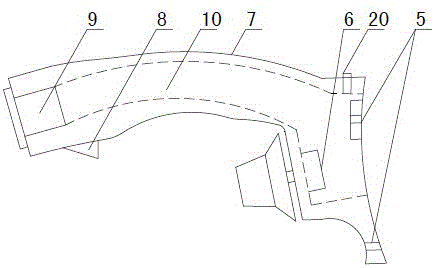

[0081] The difference between embodiment 2 and embodiment 1 is: in embodiment 2, no fully wrapped structure is adopted between the outer pot body 1 and the inner pot body 3, such as Figure 10 As shown, in this embodiment, the upper edge circumference of the outer pot body 1 is not flush with the upper edge circumference of the inner pot body 3, and the upper edge front end of the outer pot body 1 is fixed at the middle and lower part of the inner pot body 3 , that is, a half-wrapped structure is adopted. The electric heating tube 402 in the heating plate 4 extends out of the outer pot body 1, or extends into the handle cavity 10 of the control handle 2, and an outer cover 13 is arranged between the control handle 2 and the outer pot body 1, and the electric heating tube 402 and the pressure guiding tube 12 cover. Other technical means of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0083] The difference between embodiment 3 and embodiment 1 is: in embodiment 3, a pot ear 16 is arranged on the outer pot body 1, and the pot ear 16 is arranged on the other end of the outer pot body 1 opposite to the control handle 2, so it is more beneficial to The movement of the pot body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com