Cross-scale blood vessel and three-dimensional printing method thereof

A 3D printing, cross-scale technology, applied in the fields of medical science, prosthesis, additive processing, etc., can solve the problems such as the inability to realize the dynamic loading requirements of the vascular mechanism and the inability to meet the strength of the vascular cell mechanics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

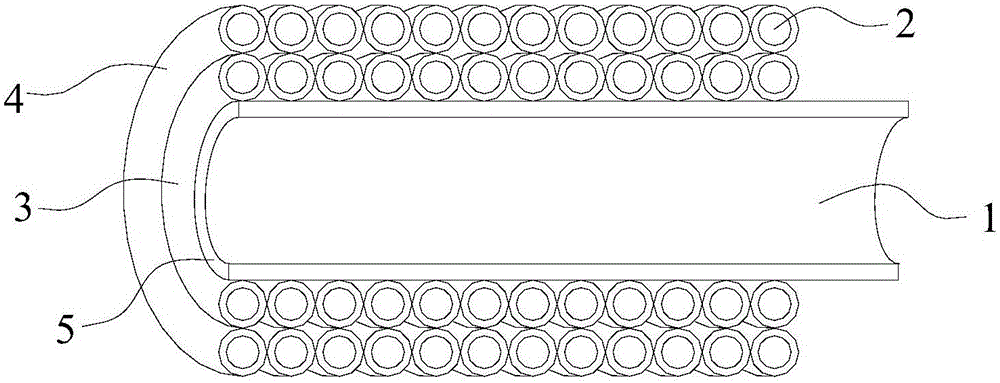

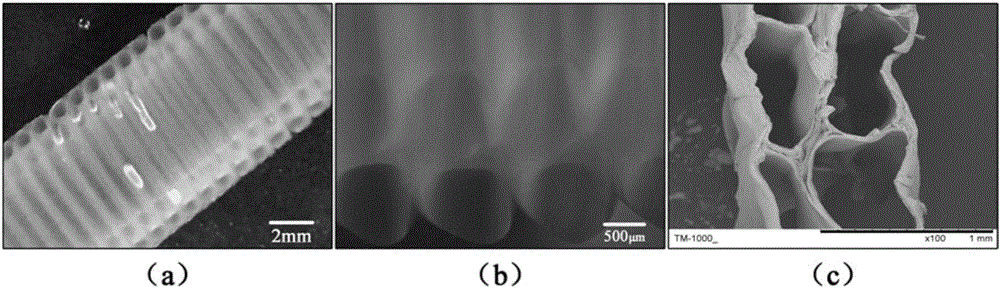

[0078] In the 3D printing method of this embodiment, mouse fibroblast L929 was selected as fibroblast, rat aortic smooth muscle cell A7r5 was selected as smooth muscle cell, and HUVEC was selected as human umbilical vein endothelial cell as vascular endothelial cell. The average outer diameter of the hollow fiber formed under this condition was 1113 μm, the inner diameter was 817 μm, and the wall thickness was 148 μm. The diameter of the rotor is 6 mm.

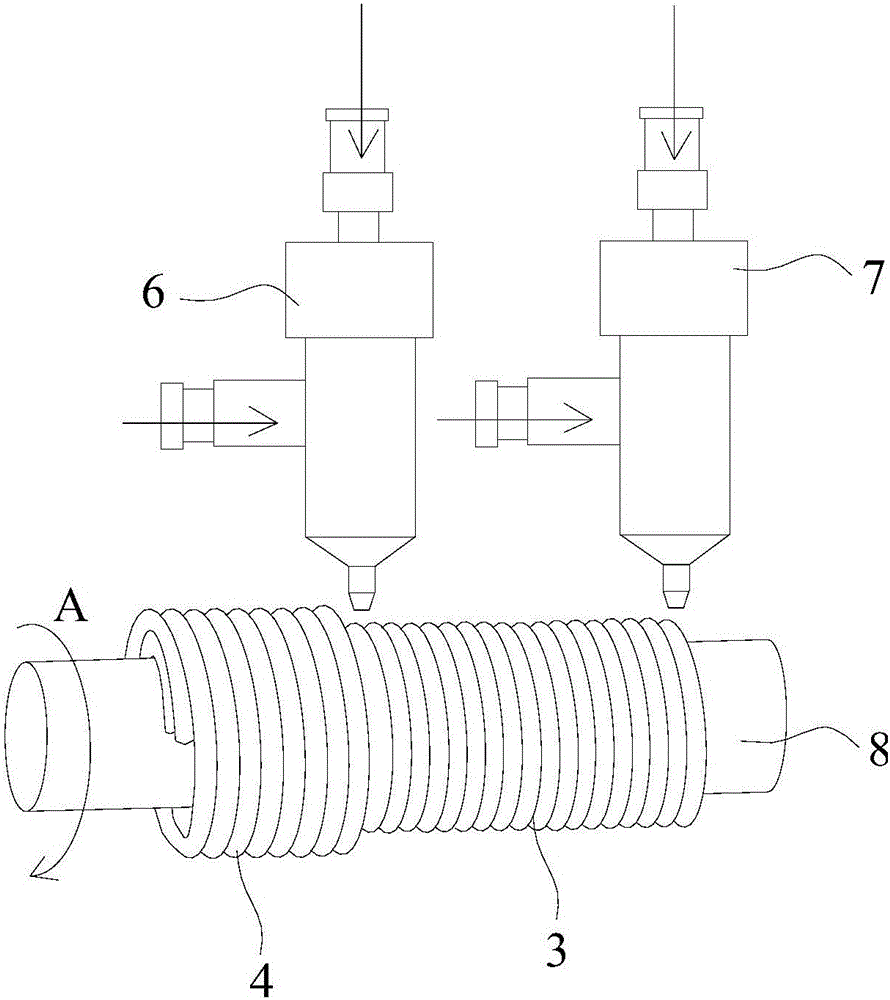

[0079] In order to print the blood vessels of the above structure, the specific implementation steps are as follows:

[0080] (1) Prepare a sodium alginate aqueous solution with a mass concentration of 8%: weigh a certain amount of biochemical grade sodium alginate powder, sterilize it under ultraviolet light for half an hour, and mix the sodium alginate powder and deionized water in proportion , a magnetic stirrer was stirred for 24 hours, the temperature was set at 60° C., and the rotation speed was 120 rpm. After being mi...

Embodiment 2

[0098] Such as Figure 5 As shown, the method of the present invention is used to print cross-scale vascular structures with different shapes. When printing these vascular structures, the difference lies in that the rotational speed of the rotator 7 and the translational speed of the spray head should be changed accordingly according to the shape of the vascular structures, and the rest of the steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap