A method for controlling deposition of gold atoms on silver nanostructures

A technology of atomic deposition and control method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of single deposition mode and no clear exploration of gold atom deposition mechanism, and achieve the control method Simple, excellent surface plasmon properties, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for controlling deposition of gold atoms on a silver nanostructure, comprising the following steps:

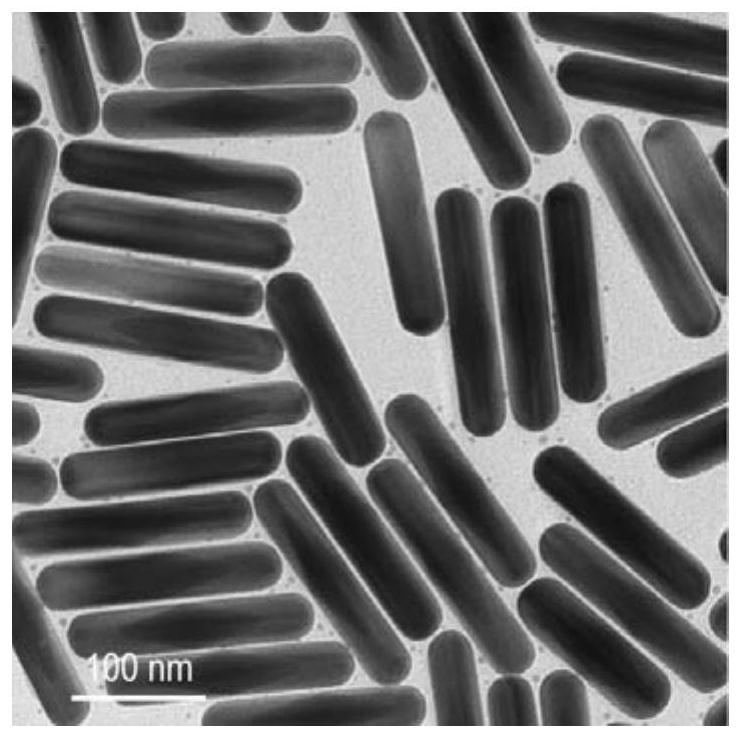

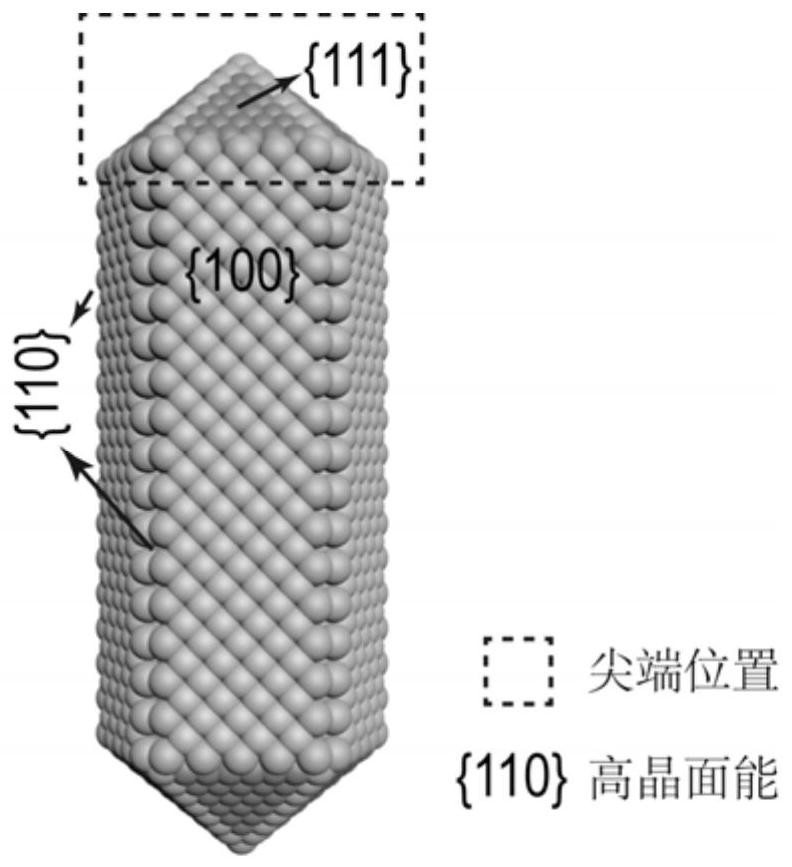

[0032] a. Add 5mL gold nano bipyramid solution to 20mL, 0.08mol / L cetyltrimethylammonium chloride solution, then add 500μL, 0.01mol / L silver nitrate solution and 250μL, 0.1mol / L silver nitrate solution Ascorbic acid solution, shake the obtained mixed solution and put it into a 65°C oven for 4.5 hours to obtain silver nanorods, such as Figures 1 to 2 As shown in the figure, the silver nanorod has a tip, a side and a side edge. The tip includes 10 {111} faces, the side includes 5 {100} faces, and the side edges include 5 {110} faces. The side edges are high surface energy surfaces. The surface energy surface and the tip position are ectopic distribution;

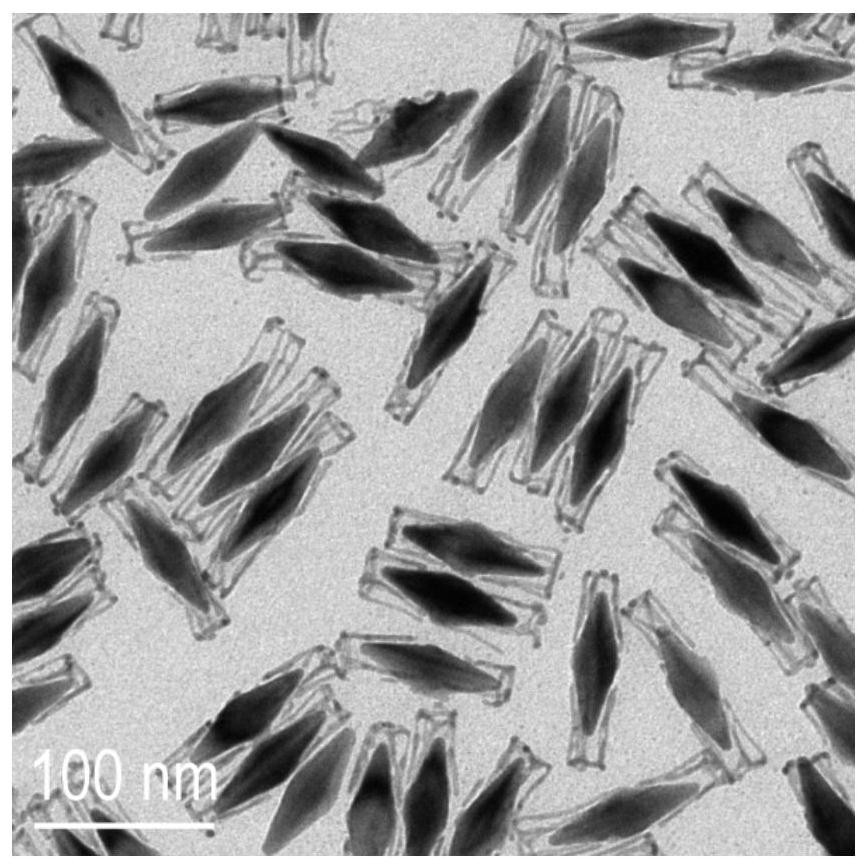

[0033] b, using the silver nanorods obtained in step a as a reaction template, centrifuge at 5000rpm for 10min, and disperse into 8mL, 0.05mol / L hexadecyltrimethylammonium bromide solution to obtain a silver ...

Embodiment 2

[0040] A method for controlling deposition of gold atoms on a silver nanostructure, comprising the following steps:

[0041] a. Add 5mL gold nano bipyramid solution to 20mL, 0.08mol / L cetyltrimethylammonium chloride solution, then add 500μL, 0.01mol / L silver nitrate solution and 250μL, 0.1mol / L silver nitrate solution Ascorbic acid solution, shake the obtained mixed solution and put it in a 65°C oven for 4.5 hours to obtain silver nanorods. The silver nanorods have a tip, a side and a side edge. The tip includes 10 {111} faces and the side includes 5 The {100} plane, the side edge includes 5 {110} planes, the side edge is a high surface energy surface, and the high surface energy surface and the tip position are ectopic distribution;

[0042]b, using the silver nanorods obtained in step a as a reaction template, centrifuge at 5000rpm for 10min, and disperse into 8mL, 0.05mol / L hexadecyltrimethylammonium bromide solution to obtain a silver nanorod solution;

[0043] c. Take 4 ...

Embodiment 3

[0049] A method for controlling deposition of gold atoms on a silver nanostructure, comprising the following steps:

[0050] a. Add 5mL gold nano bipyramid solution to 20mL, 0.08mol / L cetyltrimethylammonium chloride solution, then add 500μL, 0.01mol / L silver nitrate solution and 250μL, 0.1mol / L silver nitrate solution Ascorbic acid solution, shake the obtained mixed solution and put it into a 65°C oven to react for 4.5 hours to obtain silver nanorods. The silver nanorods have a tip, a side and a side edge. The tip includes 10 {111} faces and the side includes 5 The {100} plane, the side edge includes 5 {110} planes, the side edge is a high surface energy surface, and the high surface energy surface and the tip position are ectopic distribution;

[0051] b, using the silver nanorods obtained in step a as a reaction template, centrifuge at 5000rpm for 10min, and disperse into 8mL, 0.05mol / L hexadecyltrimethylammonium bromide solution to obtain a silver nanorod solution;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com