Movable hammer type crushing station

A hammer crushing and hammer crusher technology, applied in grain processing, etc., can solve the problems of large occupied space, inability to move, large investment in crushing station infrastructure, etc., and achieve the effect of reducing the occupied area and moving flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

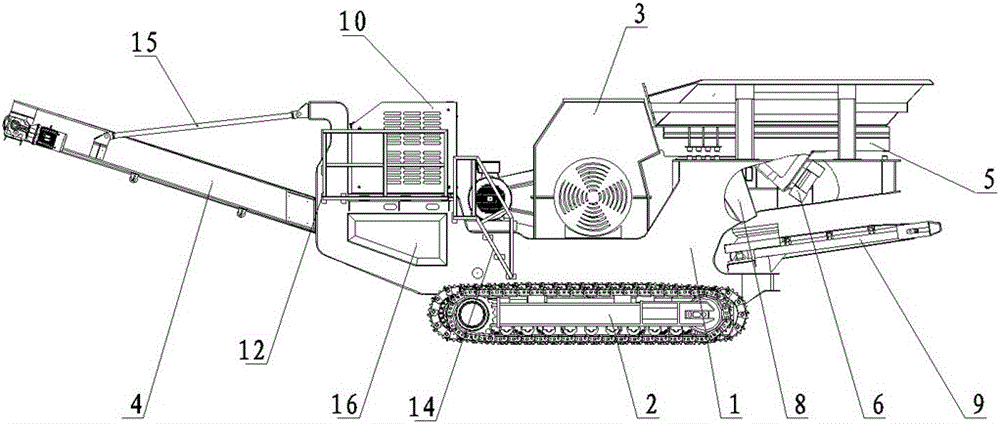

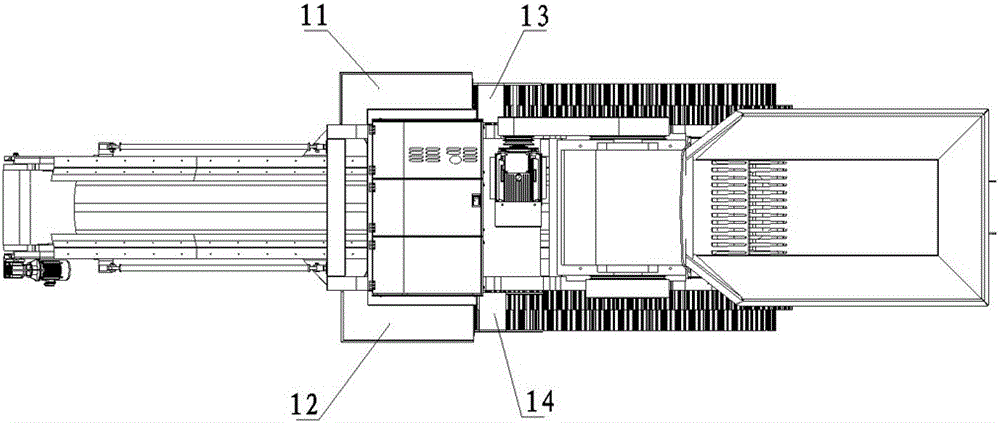

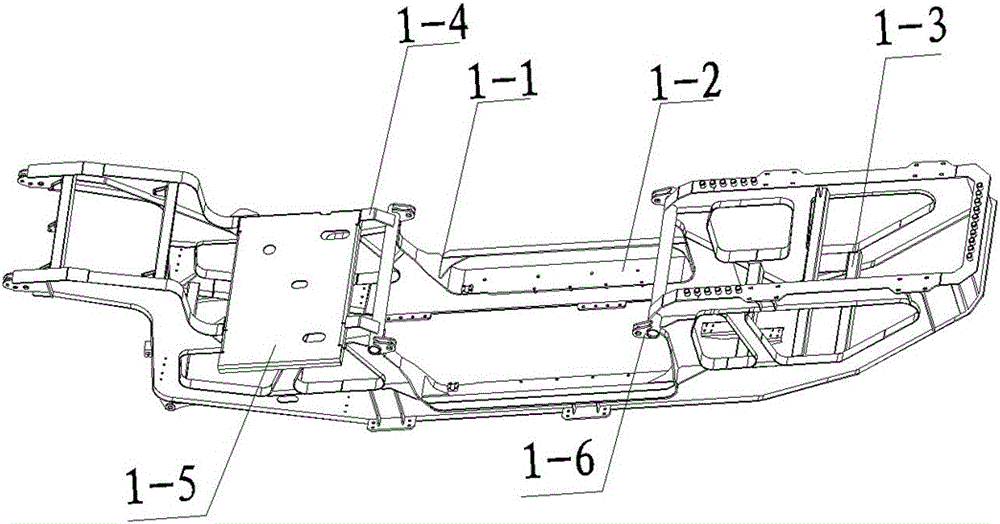

[0013] figure 1 and figure 2 The mobile hammer crushing station shown includes a hammer crusher 3, a front conveyor belt 4, a vibrating feeding screen 5 and a power box 10, the vibrating feeding screen 5 is arranged on one end of the vehicle frame 1, and the power box 10 is arranged on On the other end of the vehicle frame 1, a hammer crusher 3 is provided between the vibrating feed screen 5 and the power box 10 on the vehicle frame 1, and a front conveyor belt 4 is provided under the outlet of the hammer crusher 3 to vibrate. The bottom of the feeding screen 5 is provided with a transfer hopper 8, the outlet of the transfer hopper 8 is provided with a tail conveyor belt 9, and the lower end of the vehicle frame 1 is provided with a running device 2, which is a crawler belt running device; One side of 1 is provided with the electrical box 16 that is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com