Intelligent automatic sorting and weighing device

An automatic sorting and weighing device technology, applied in sorting, measuring devices, weighing and other directions, can solve problems such as low work efficiency and slow speed, and achieve the goal of saving personnel costs, improving work efficiency, and enhancing weighing functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

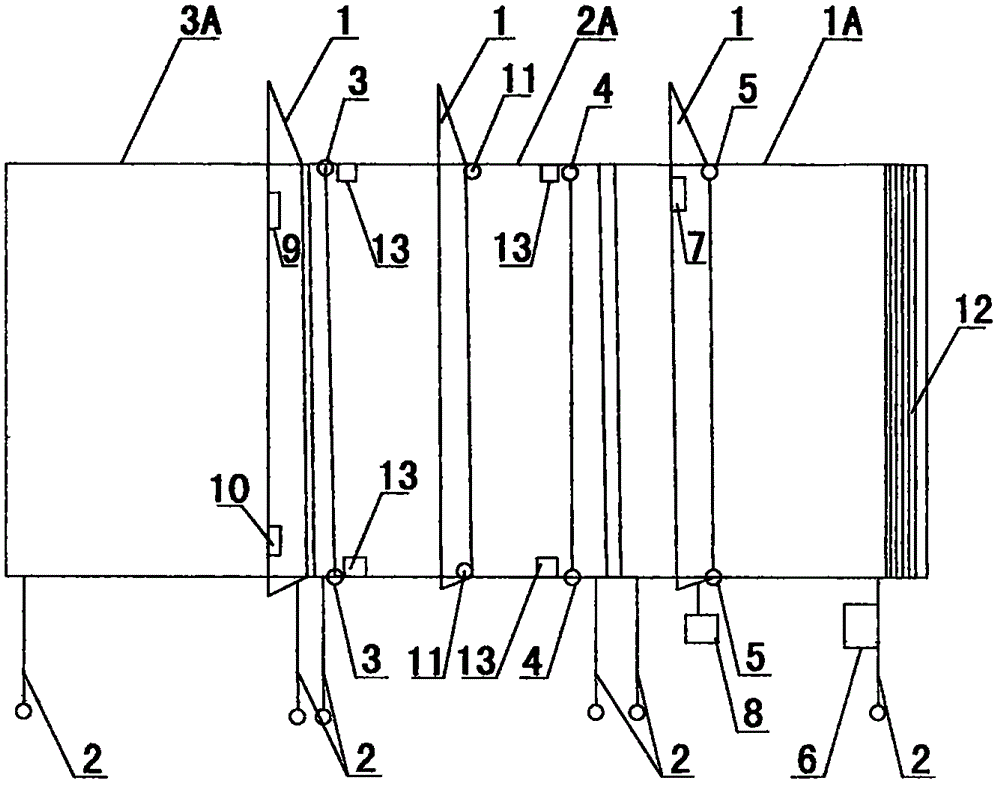

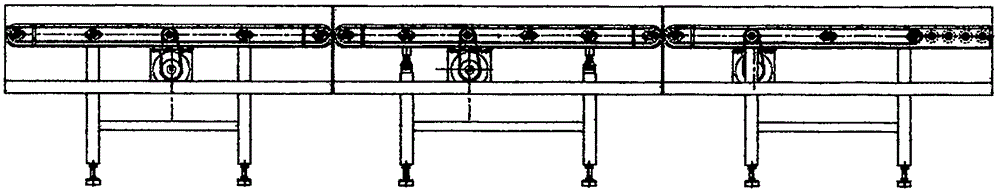

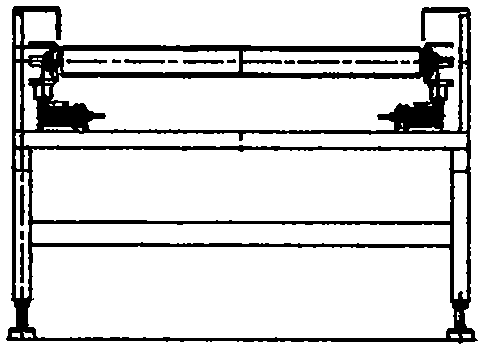

[0030] Such as Figure 1-5 As shown, the intelligent automatic sorting and weighing device described in the embodiment of the present invention is composed of the system sorting section 1A, the system weighing section 2A, and the system bag pulling section 3A spliced in sequence from right to left, and the system sorting section The junction of 1A and system weighing section 2A, the center of the outer edge of system weighing section 2A, and the right edge of system pulling section 3A are respectively provided with brackets 1 for placing and installing other instruments;

[0031] Correspondingly, six weighing feet 2 are arranged on both sides of the system sorting section 1A, the system weighing section 2A, and the system pulling section 3A, and there are photoelectric switch groups 13 at the edges of the system pulling section 3A. wherein the system weighing section 2A has photoelectric switch groups 4 for length measurement at the edges on both sides, and the system sortin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com