High-precision aluminum alloy bending machine

A technology of aluminum alloy and bending machine, which is applied in the field of mechanical bending equipment design, can solve the problems of inability to achieve multi-angle bending and high angle accuracy, and achieve the effect of improving bending efficiency, improving bending accuracy, and smoothing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

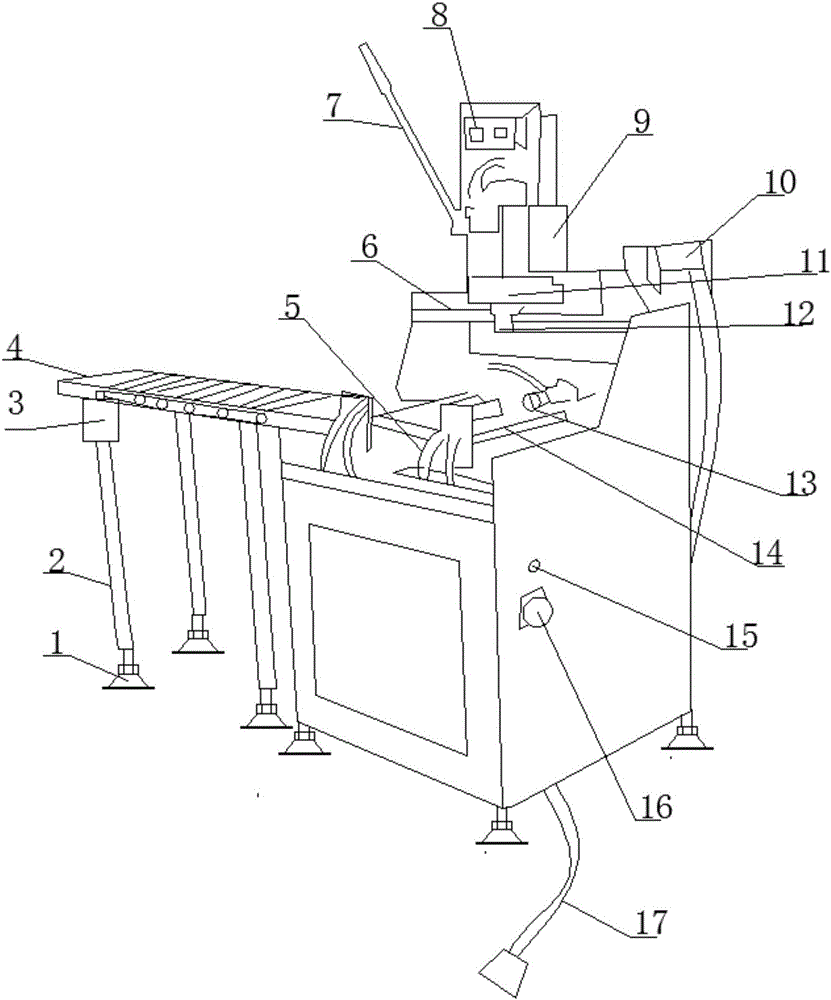

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, a high-precision aluminum alloy bending machine includes a bottom fixed suction cup 1, a transmission table 4, a cylinder 9, a moving frame 6, and a workbench 14. A support frame 2 is arranged above the bottom fixed suction cup 1, and a There is a drag motor 3, and the drag motor 3 is used to provide power to the transfer table 4, and a transfer table 4 is arranged above the drag motor 3, and the transfer table 4 is used to transfer aluminum alloy plates, and a gas pipe 5 is arranged on the side of the transfer table 4, Trachea 5 below is provided with pedal valve 17, and pedal valve 17 effect is equivalent to switch, and pedal valve 17 top is provided with emergency stop button 16, and emergency stop button 16 takes this button during emergency, and emergency stop button 16 top is provided with Work indicator light 15, workbench 14 is arr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap