Puncher pin mechanism with buffer function

A punch and functional technology, applied in the field of die processing, can solve the problems of easy wear, shorten the service life of the punch, and not cooling down in time, so as to reduce wear, prolong the service life and facilitate cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

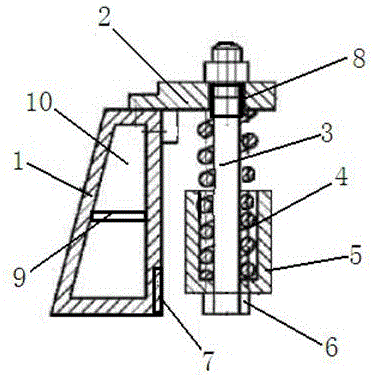

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] Such as figure 1 As shown, the punch mechanism with cushioning function of the present invention includes a support seat 1 with a right-angled trapezoidal cross section, a stamping plate 2 is fixed on the upper side of the support seat 1, and a stamping rod runs vertically downward on the stamping plate 2 3. The outer wall of the punching rod 3 located below the punching plate 2 is sleeved with a buffer spring 4 , the outer wall of the buffer spring 4 is sleeved with a spring protection sleeve 5 , and the lower end of the punching rod 3 is screwed with a punch 6 , the twisted punch 6 is easy to replace, and the right-angle side of the support seat 1 on the side of the punch 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com