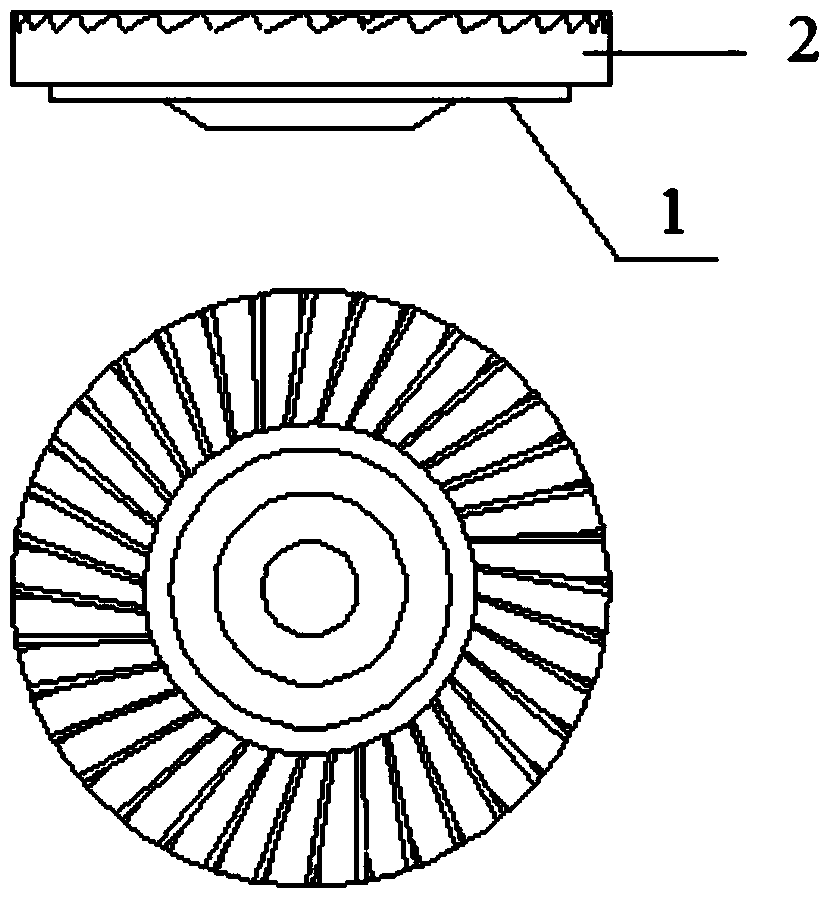

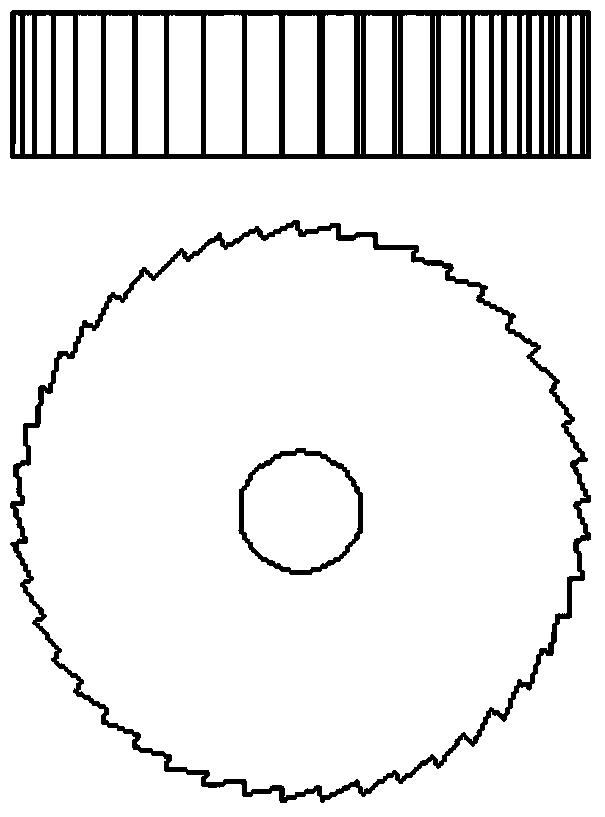

Grinding wheel containing grinding materials and thermal expansion resin hollow microspheres

A hollow microsphere, thermal expansion technology, used in abrasives, bonded grinding wheels, metal processing equipment, etc., can solve problems such as poor heat dissipation, natural fiber carbonization, failure, etc., to improve service life, avoid breakage and drop, improve structure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

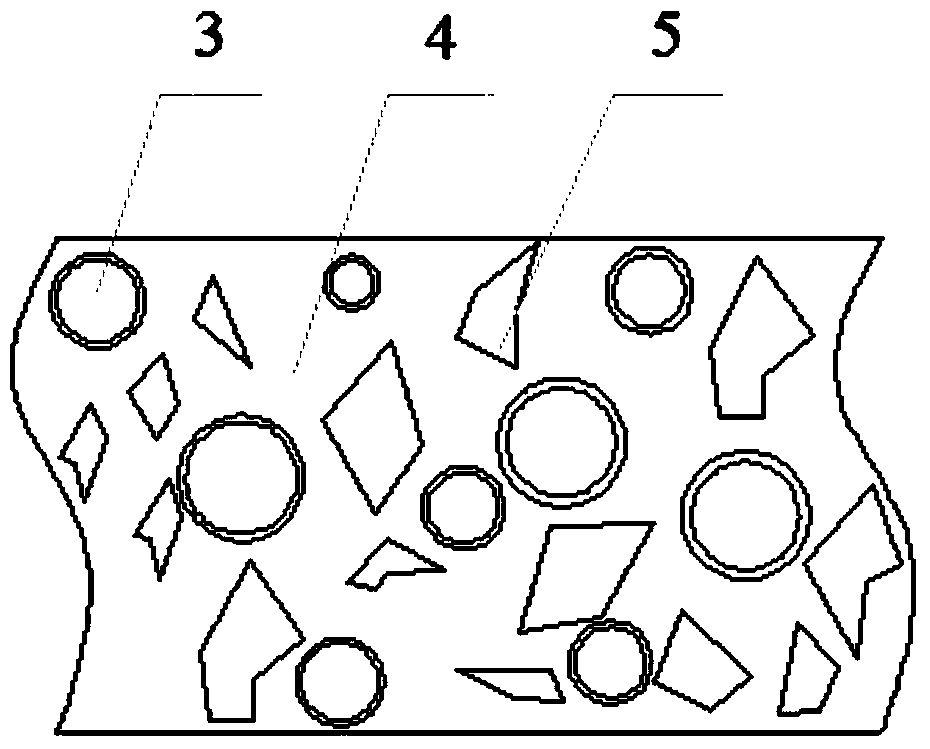

[0030] Example 1 (exploring the relationship between the addition of thermally expandable resin hollow microspheres and the polishing effect)

[0031] Explanation: The proportion of binder and abrasive in this formula is determined by mixing the binder and abrasive in different proportions and making splines for curing, then testing the mechanical performance indicators such as elastic modulus, tensile strength, elongation at break, etc. It is determined by screening out a large number of experimental data.

[0032] Proportion:

[0033]

[0034] 1 sample production

[0035] 1. Sample making

[0036] 1.1 Mixing: according to the ratio of each style formula in formula 1, weigh the natural fibers in turn, (such as making a plane polishing wheel for flat polishing, use a fine number, and make a circumferential polishing wheel for circumferential polishing, then use a thick number), in the stirring state Add the heat-expandable resin hollow microspheres to ensure uniform stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com