Patents

Literature

59results about How to "Reduce manual work time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for positioning Ethernet loop

InactiveCN101931573AControl SweepstakesImprove maintenance efficiencyData switching networksBroadcast radiationEthernet

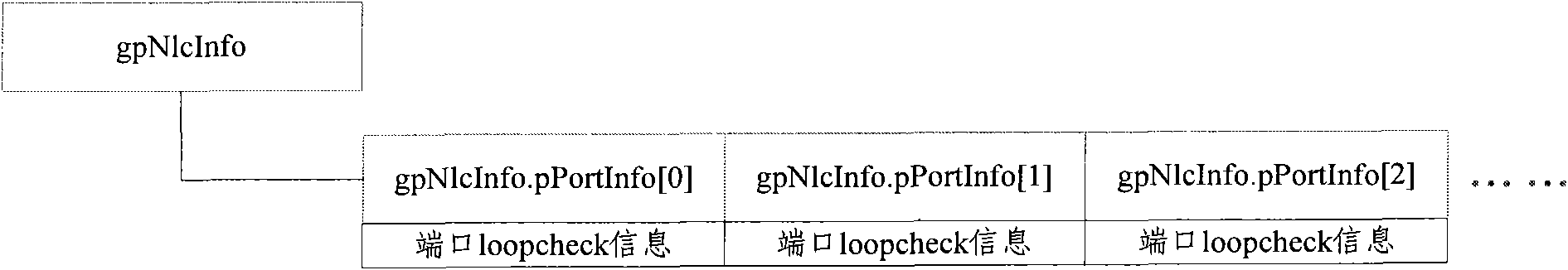

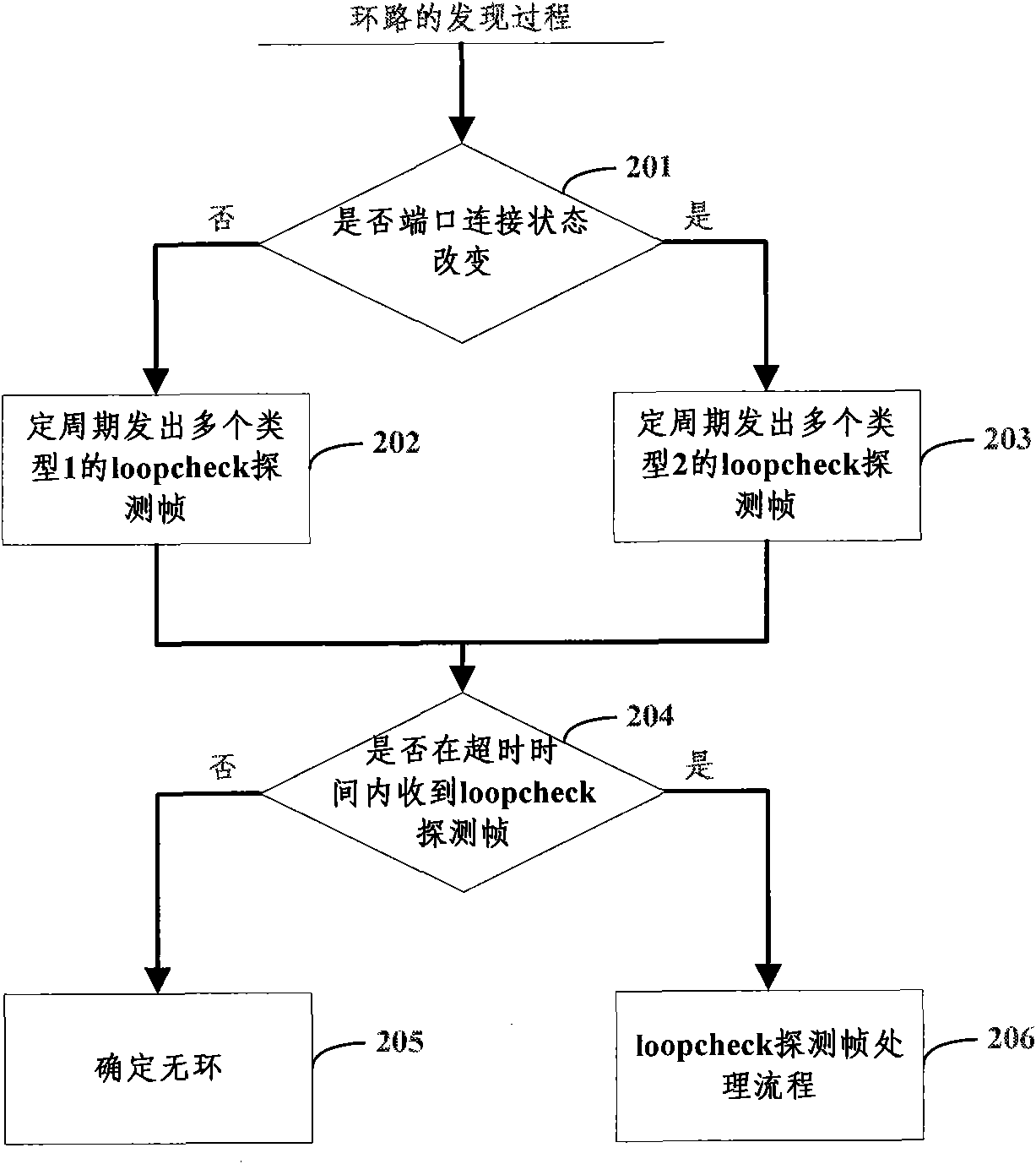

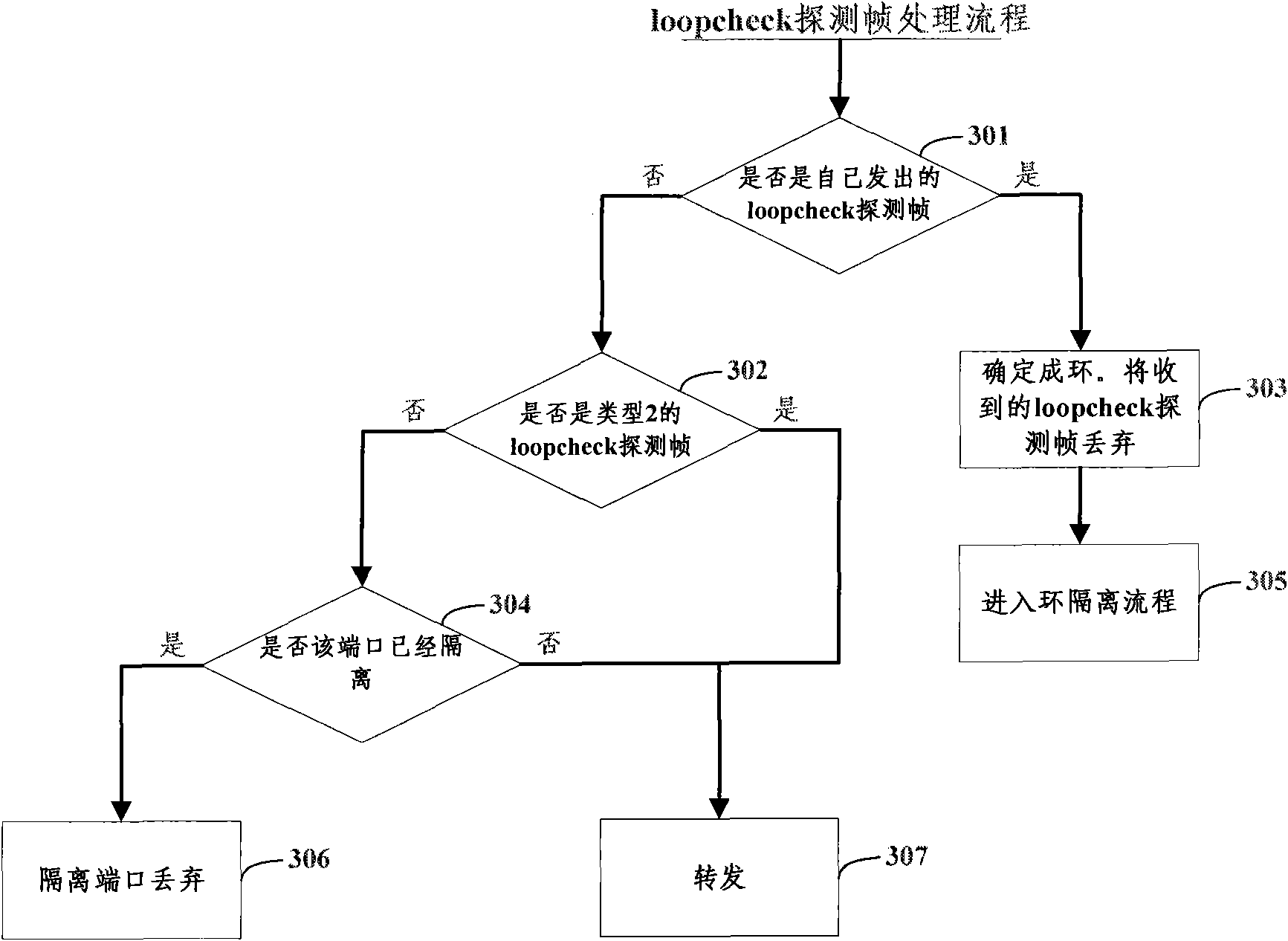

The invention discloses a method for positioning an Ethernet loop. The method comprises the following steps of: A, finding the loop in a loopcheck software module; B, processing when a port receives a loopcheck explorer frame; and C, when determining that the loop exists in a network, isolating the port where the loop is. A network logical entity uses the method for positioning the Ethernet loop, such as network nodes of a transparent network bridge, an Ethernet switch or a router; and when the loop or a broadcast storm caused by the loop occurs, a network looping failure can be removed by the method and loop points are positioned by adopting corresponding measures, so that the range which the broadcast storm is spread to can be controlled and the efficiency of network maintenance can be greatly improved.

Owner:FENGHUO COMM SCI & TECH CO LTD

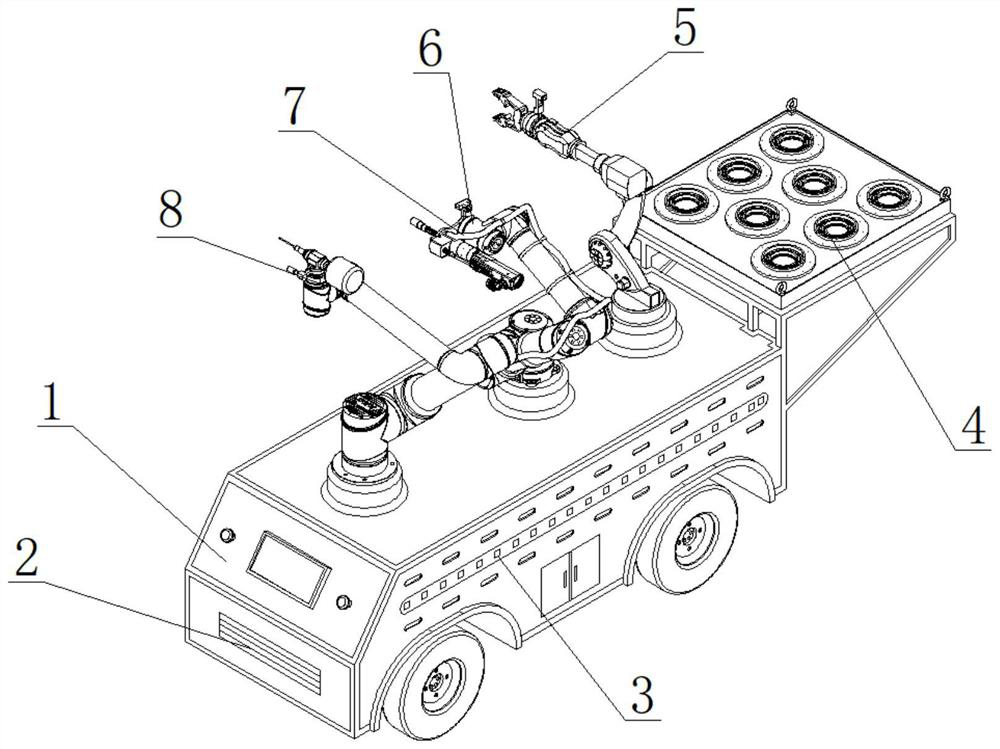

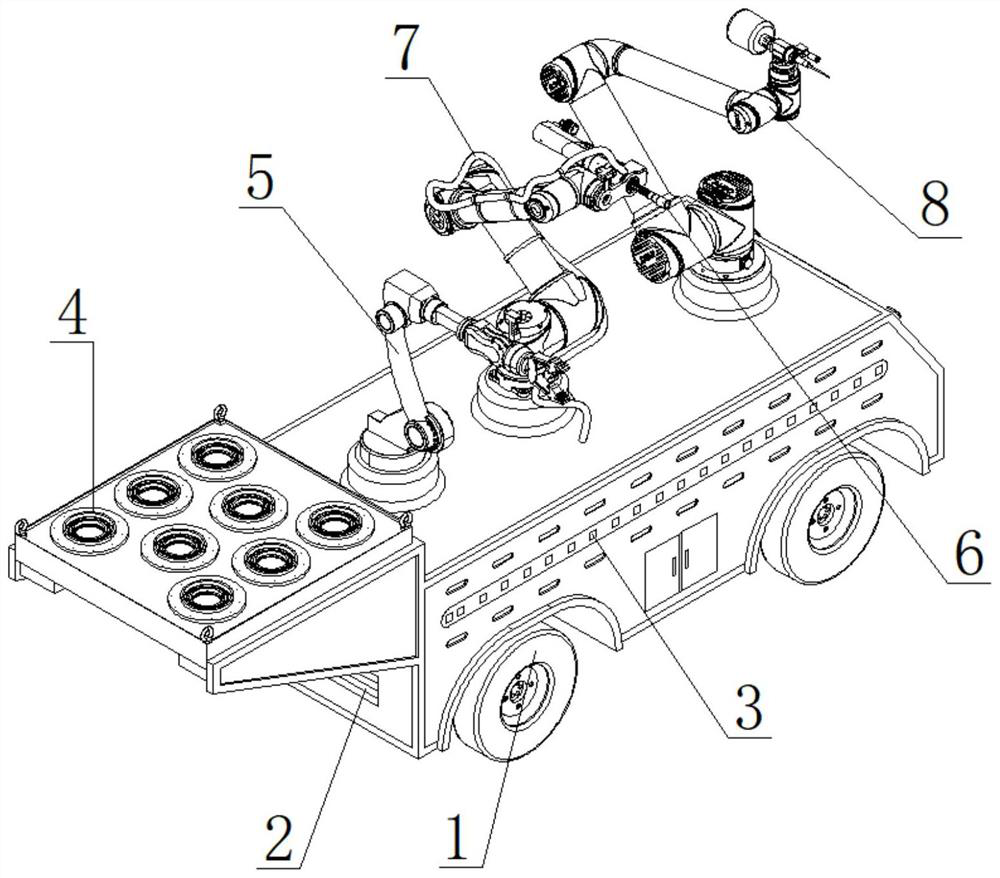

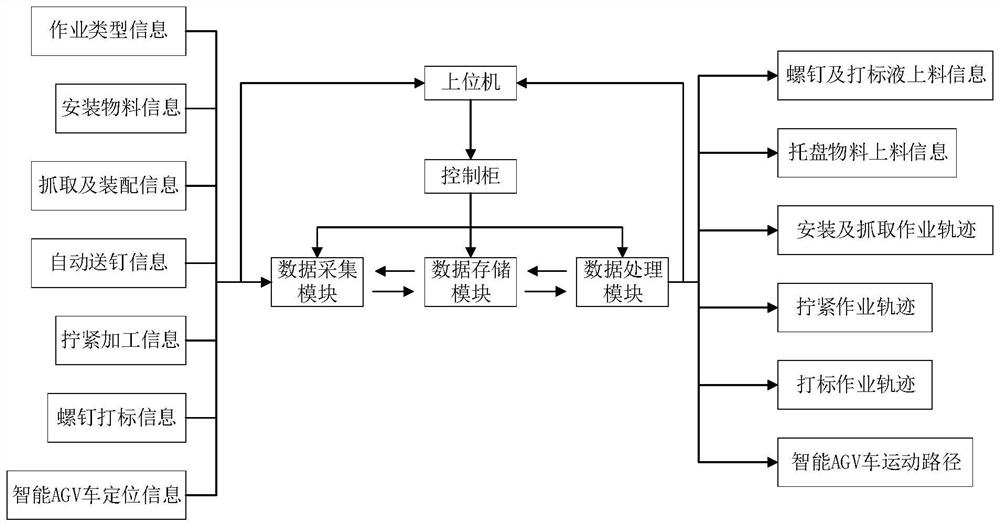

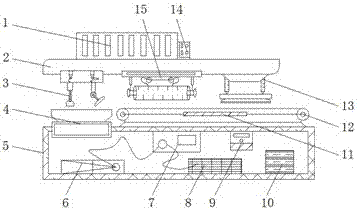

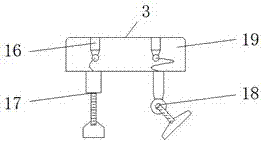

Intelligent assembly system and intelligent assembly method using repair workshop robot

ActiveCN111761347ALabor savingImprove work efficiencyProgramme-controlled manipulatorGripping headsRobot controlFastener

The invention belongs to the field of assembly using a repair workshop, and particularly discloses an intelligent assembly system and intelligent assembly method using a repair workshop robot. The system comprises an intelligent AGV, an integrated operation module, a tray material module, a material port and a control module, wherein the integrated operation module comprises a grabbing and assembling robot, an automatic nail feeding device, a tightening robot and a fastening bolt marking robot; and the control module is used for planning an operation track according to the operation type, andcontrolling the intelligent AGV, the integrated operation module, the tray material module and the material port to work cooperatively according to the operation track. The method comprises the following steps of planning a movement path of the intelligent AGV, grabbing mounting materials, mounting fasteners on fastening holes of the mounting materials and fastening, and marking the fastened fasteners. According to the intelligent assembly system and intelligent assembly method using the repair workshop robot, an automatic assembly process of parts, an automatic screwing process of screws andan automatic anti-loose marking process of the fastened screws are combined, so that the labor is reduced, and the operation efficiency is improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

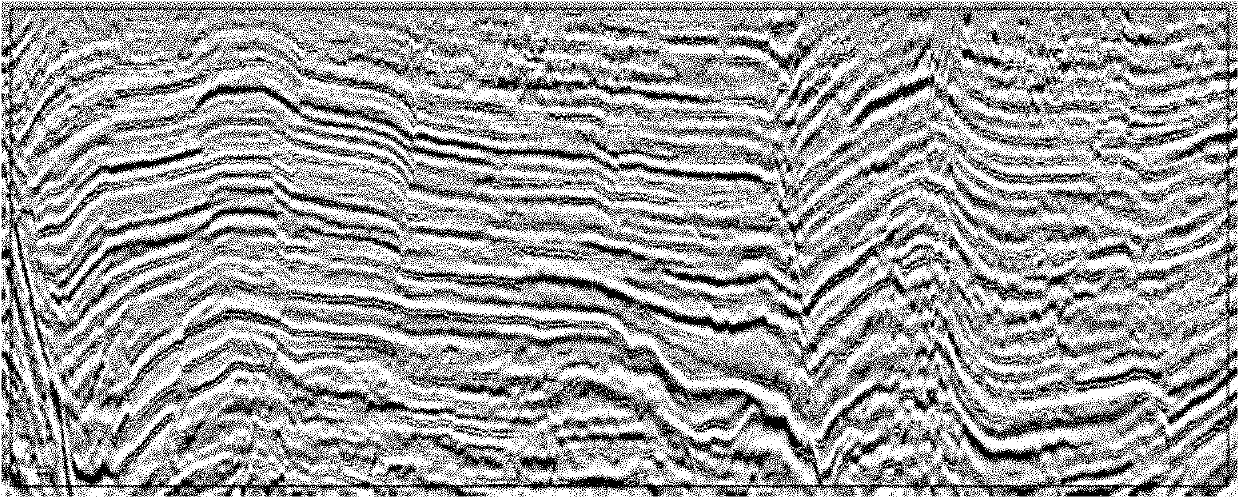

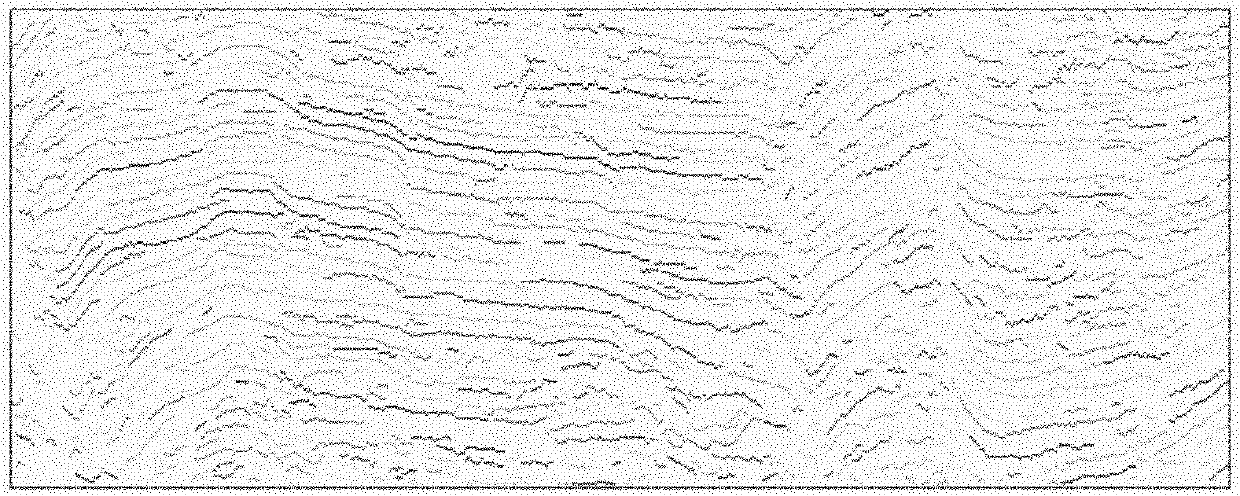

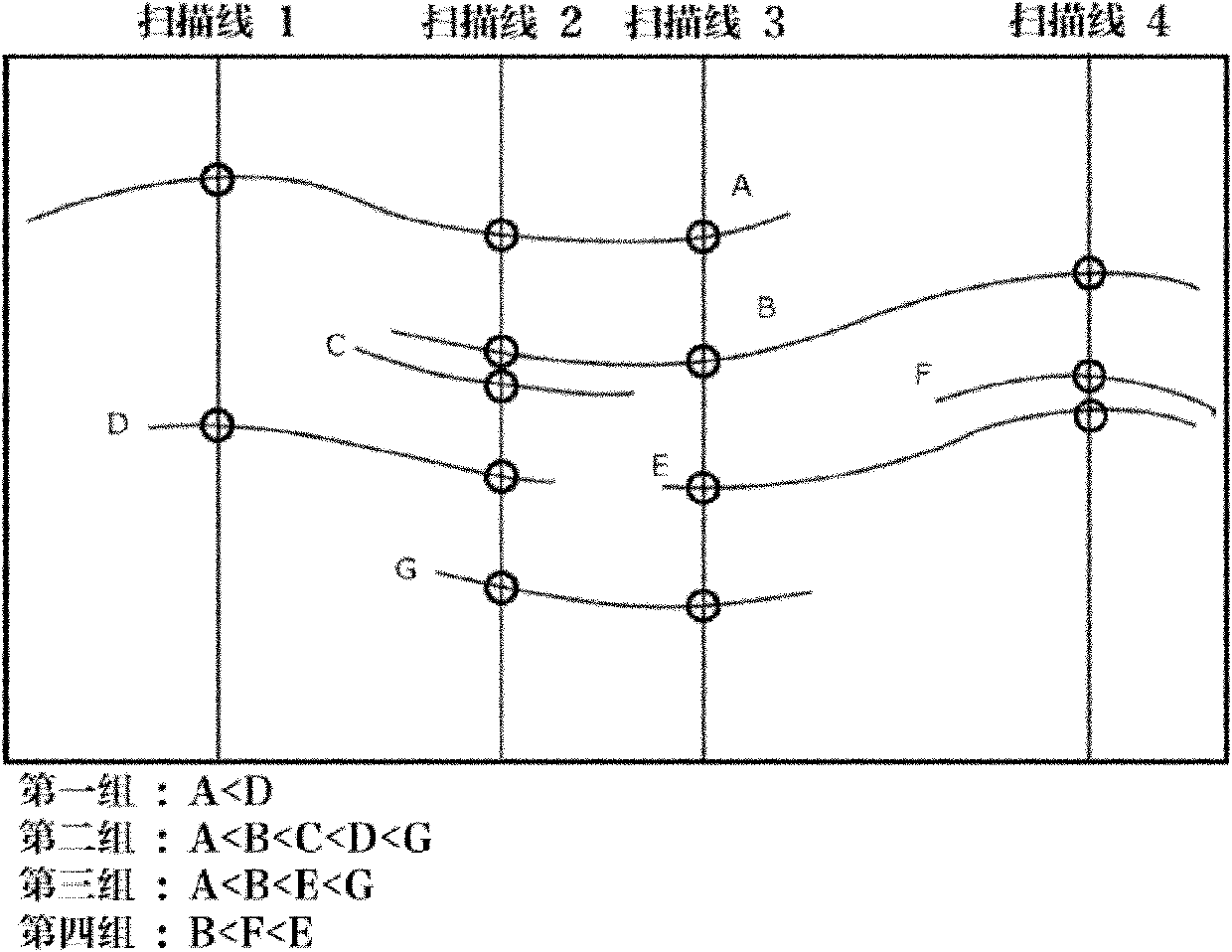

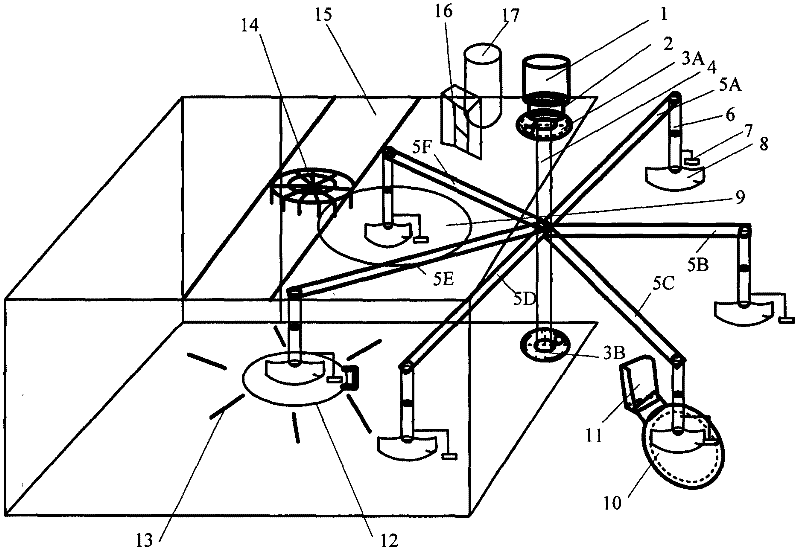

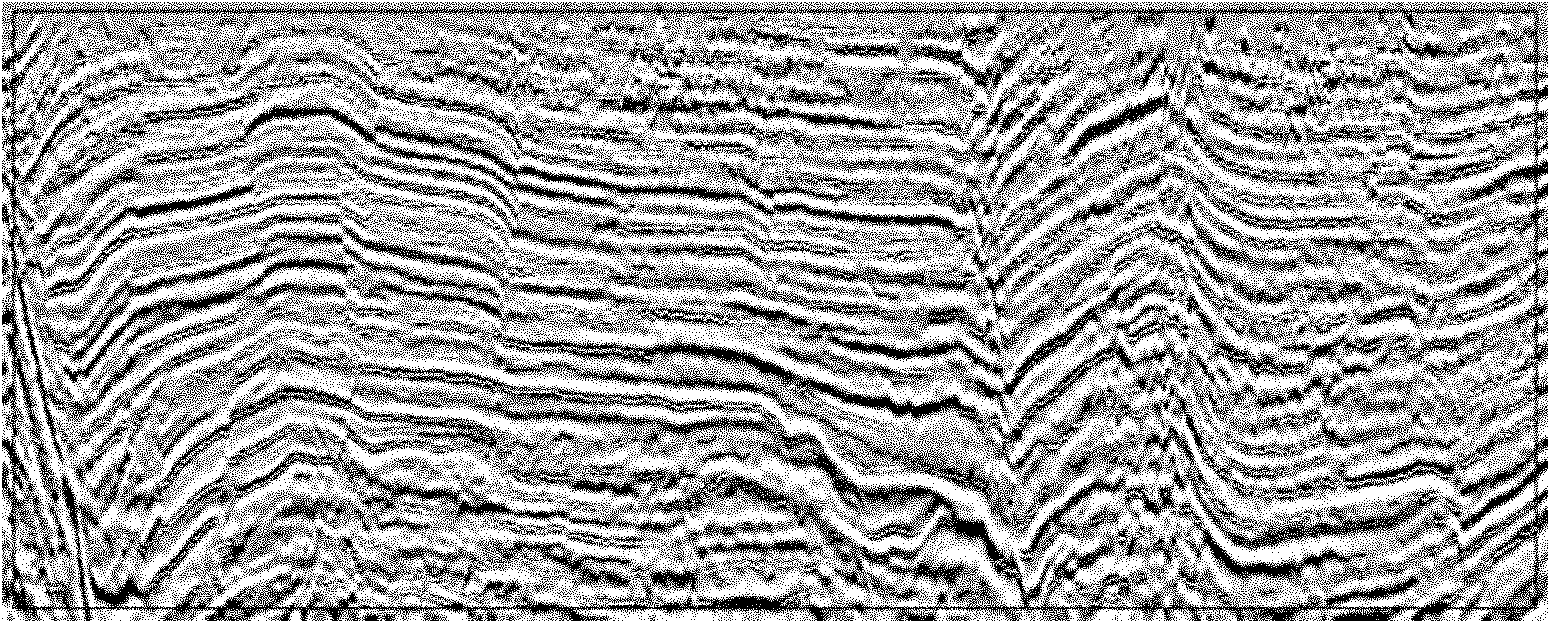

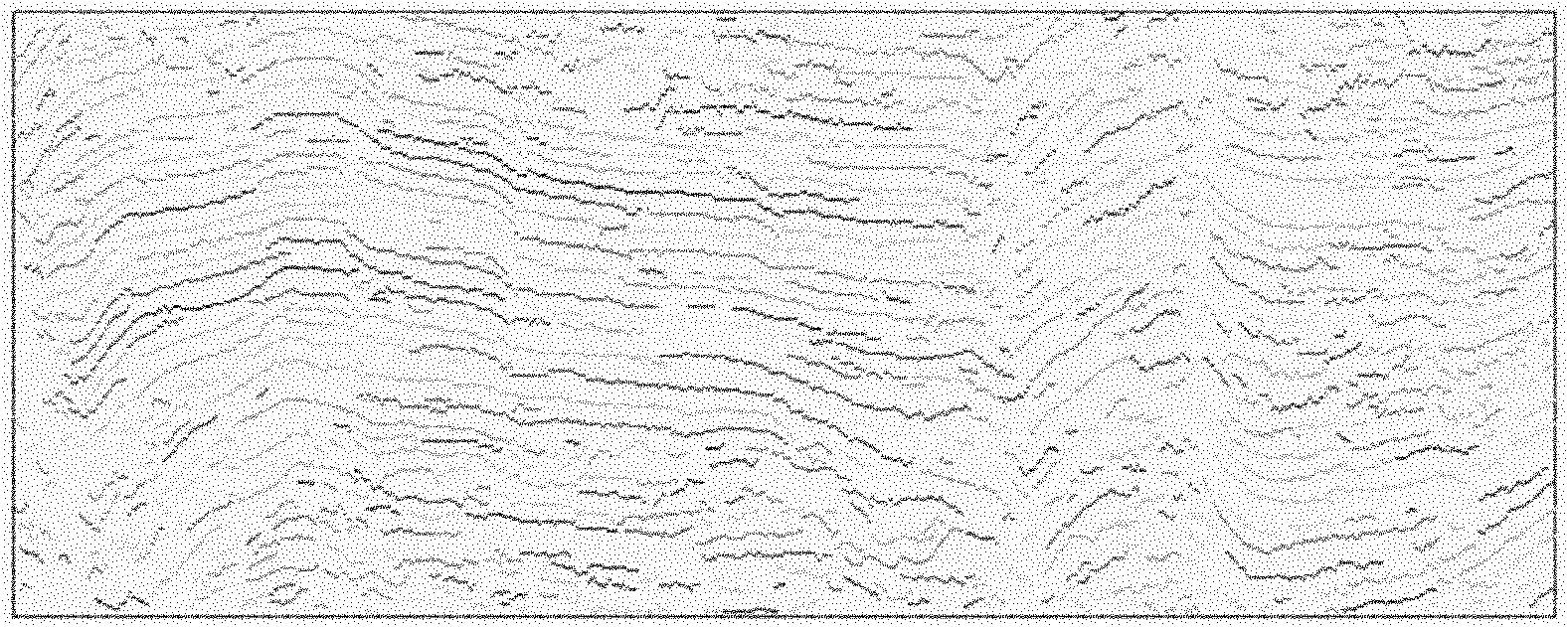

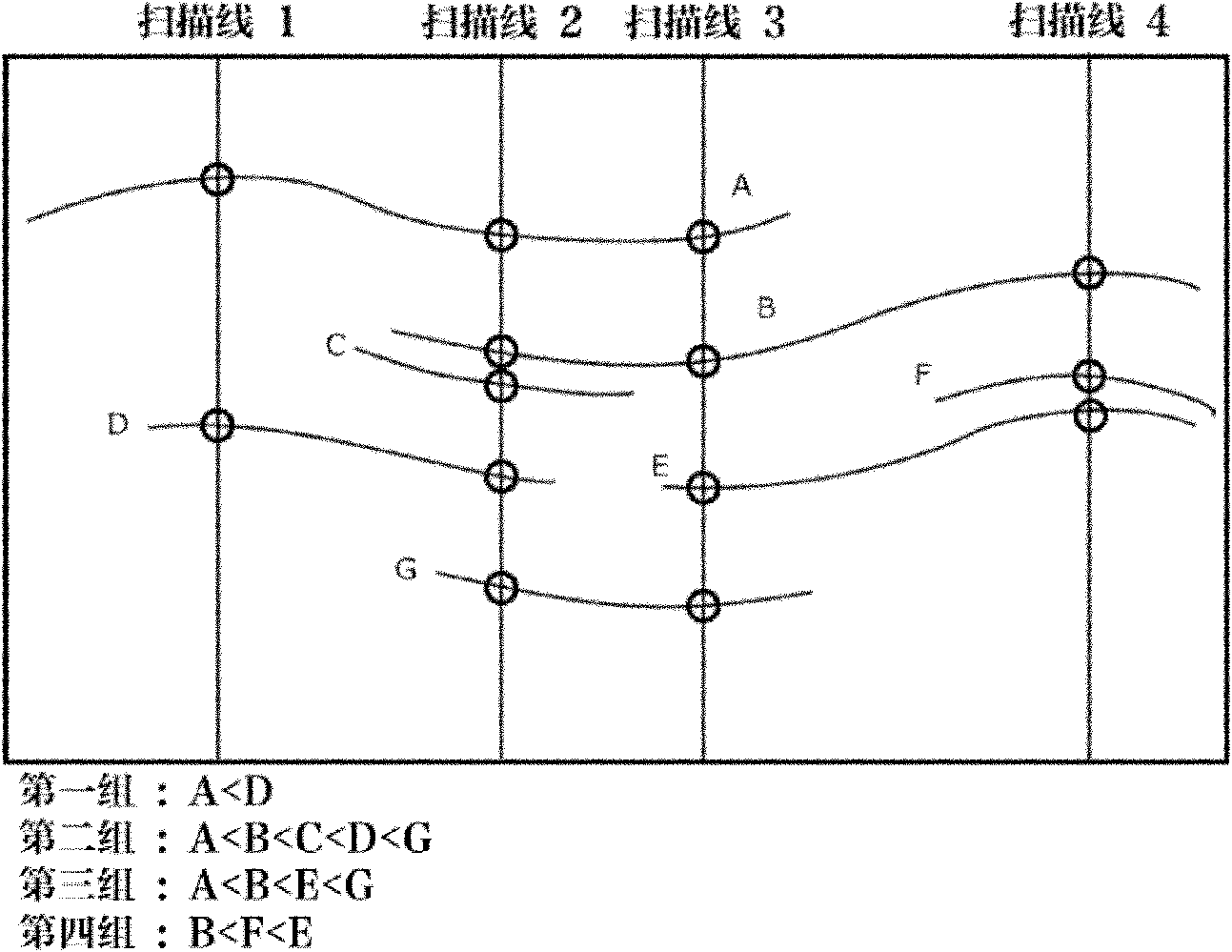

Hierarchical sequence analysis method oriented to generation of three-dimensional hierarchical grids

ActiveCN102176052AFully automatedImprove processing efficiencySeismic signal processingSequence analysisStructure analysis

The invention discloses a hierarchical sequence analysis method oriented to the generation of three-dimensional hierarchical grids, which is used for geologic stratum modeling and underground structure analysis, and is characterized by comprising the following steps of: scanning surface patches consisting of discrete points; establishing a target function according to the scanned result; solving the solution of the target function in case of a minimum value, and considering the solution as a sequence value of the surface patches; and classifying the surface patches by using the sequence value, and considering classified surface patches as data of the generation of the hierarchical grids. When the method disclosed by the invention is adopted, the automatic classification of automatic tracking results of axes in the same direction can be realized, and therefore, automatic explanation can be completed, and heavy manual classification and pickup can be eliminated; moreover, efficiency of the explanation process from a seismic data body to a hierarchical grid modeling is effectively improved.

Owner:北京网格天地软件技术股份有限公司

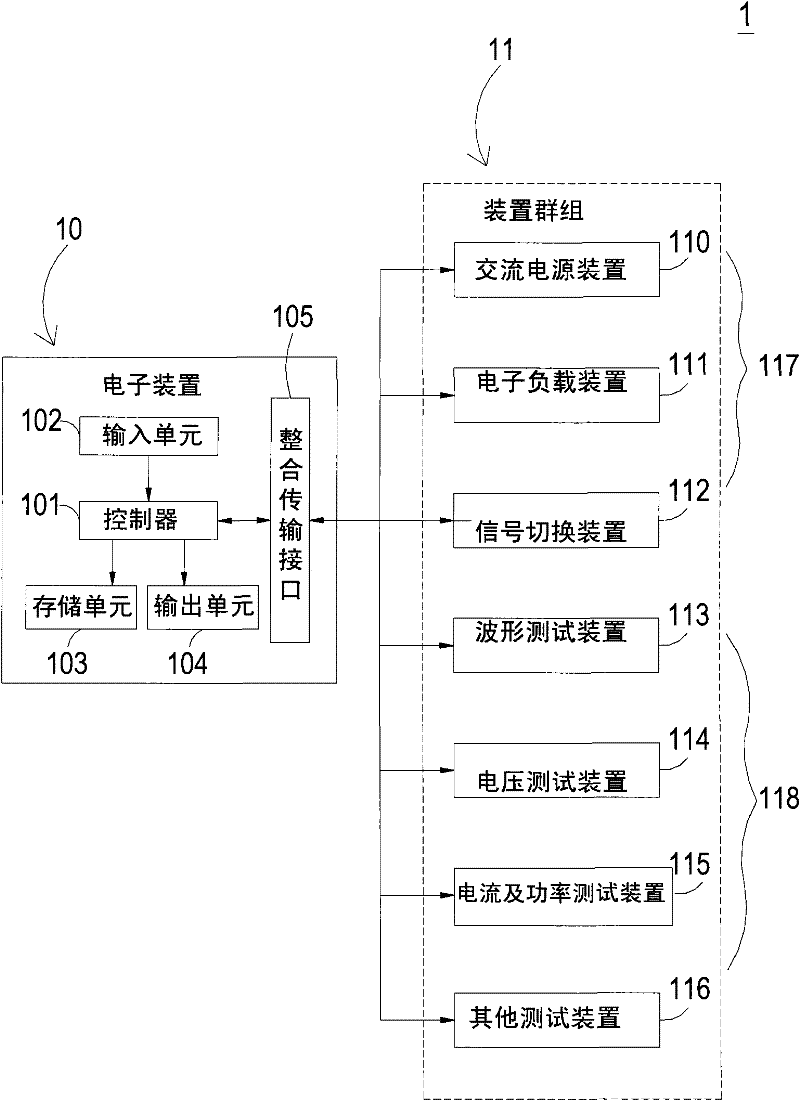

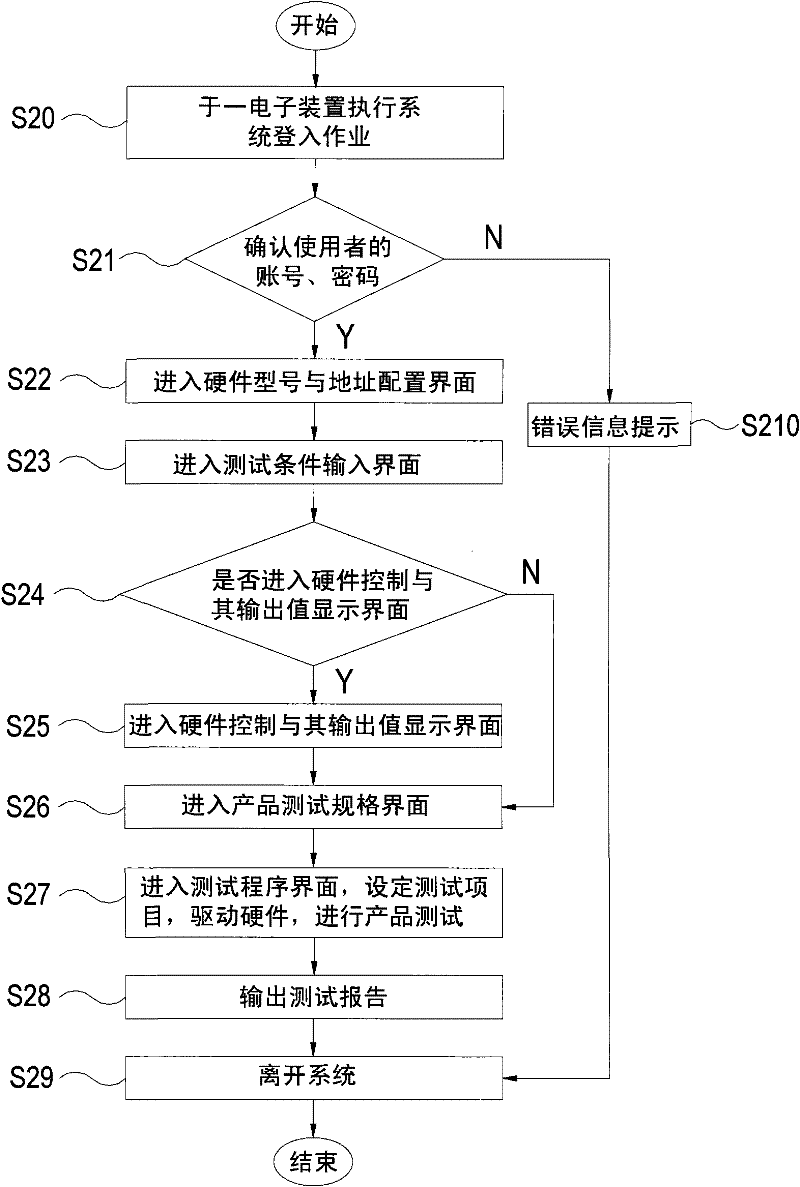

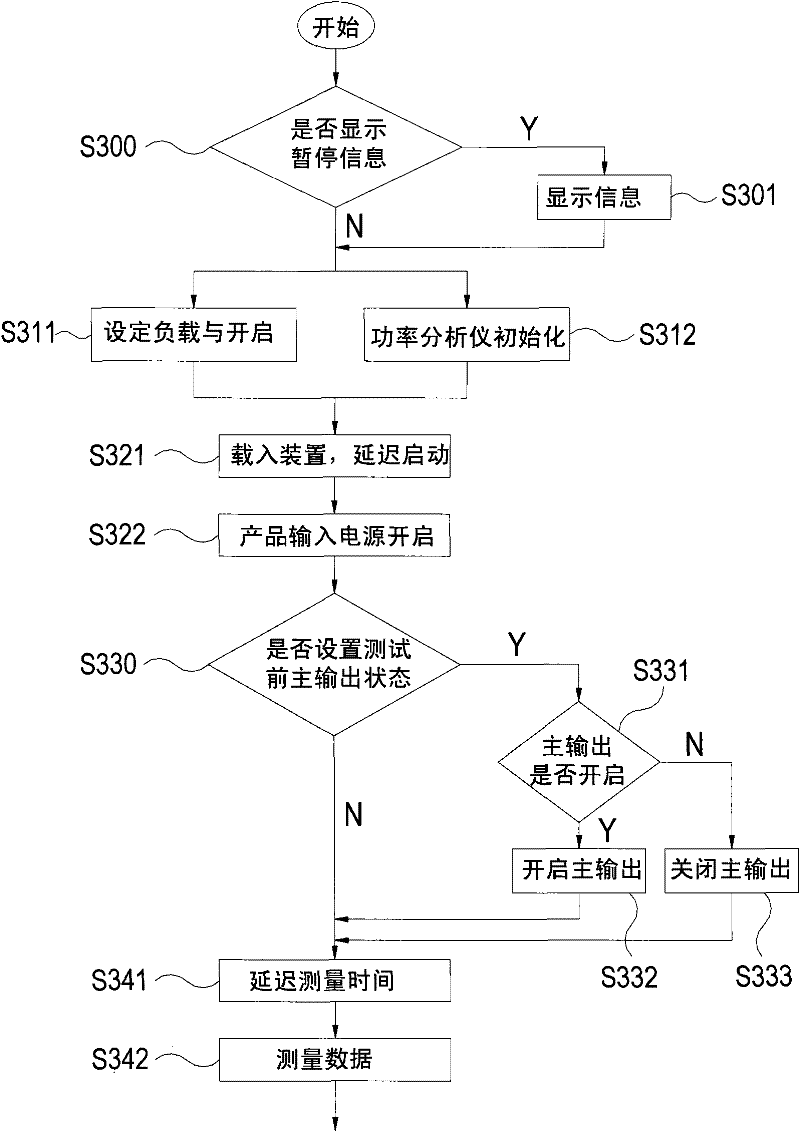

Automatic test system and method thereof

InactiveCN102455414AHigh precisionImprove test efficiencyPower supply testingProgramme control in sequence/logic controllersTest efficiencyTested time

Owner:DELTA ELECTRONICS INC

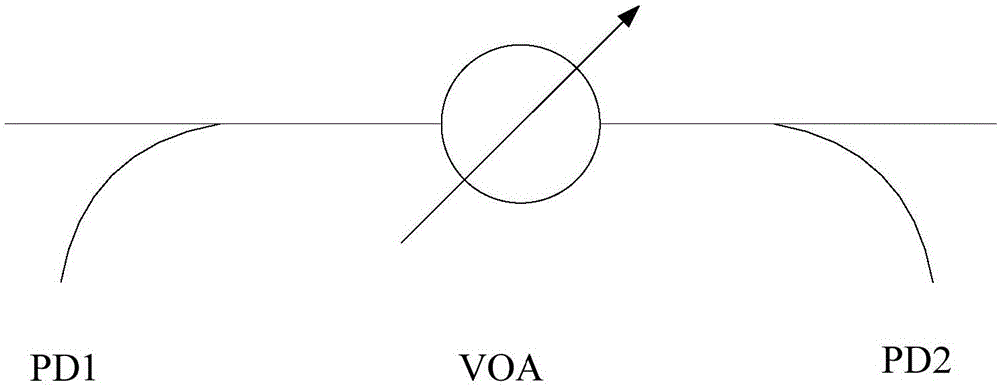

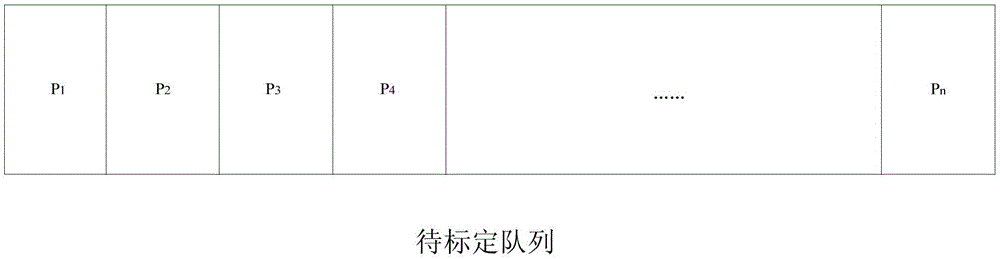

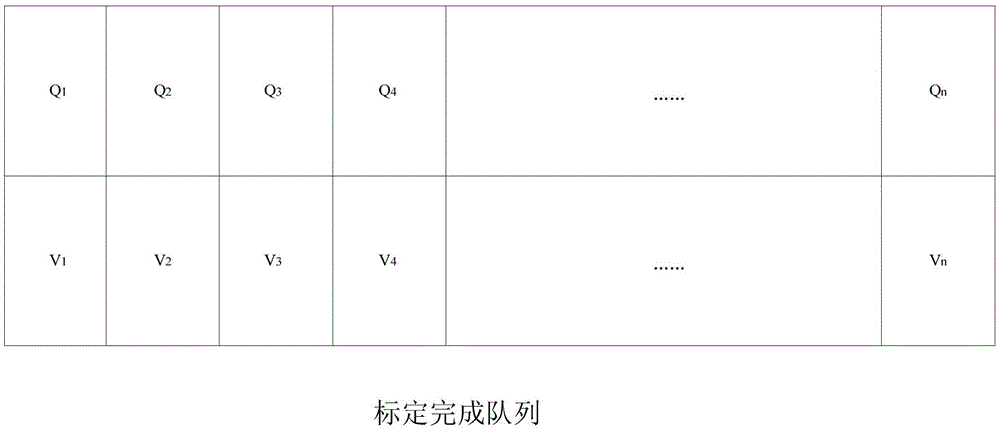

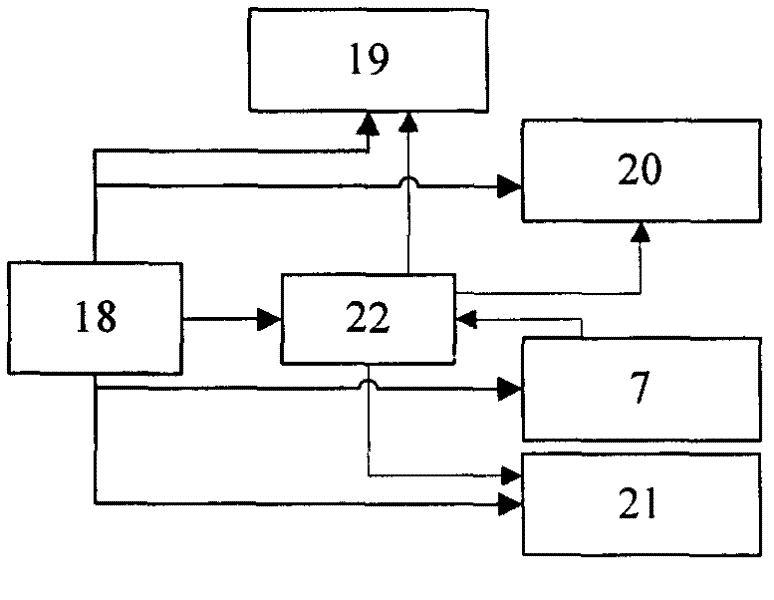

Variable optical attenuator control method and system based on automatic calibration and intelligent learning

ActiveCN105159080AReduce manual work timeLow costCoupling light guidesAdaptive controlUltrasound attenuationControl engineering

The invention provides a variable optical attenuator control method and system based on automatic calibration and intelligent learning. The control method comprises an automatic attenuation calibration process, a rapid attenuation control process and an intelligent self-learning process. During the automatic attenuation calibration process, a to-be-calibrated queue is determined, an attenuation value of a variable optical attenuator is set to be a minimum value, a parameter setting value of the variable optical attenuator is increased gradually by a minimum step size, and a corresponding calibration parameter value of the to-be-calibrated attenuation value is obtained. During the rapid attenuation control process, a position of a target attenuation value in a calibrated queue is searched and confirmed, a corresponding target setting parameter value of a target attenuation value is calculated, and setting and fine tuning are carried out based on a result. And during the intelligent self-learning process, a current actual light attenuation value is obtained based on sampling and correction is carried out when determination is needed. According to the invention, an automatic attenuation calibration way without manual intervention is provided; long-term influences caused by factors of an environment and device aging and the like can be eliminated based on intelligent self-learning control; and the control precision is guaranteed.

Owner:GUANGXUN SCI & TECH WUHAN

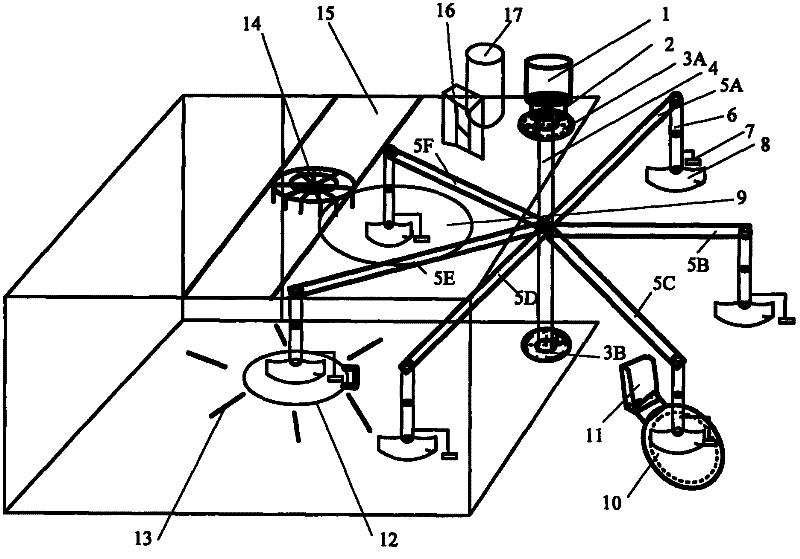

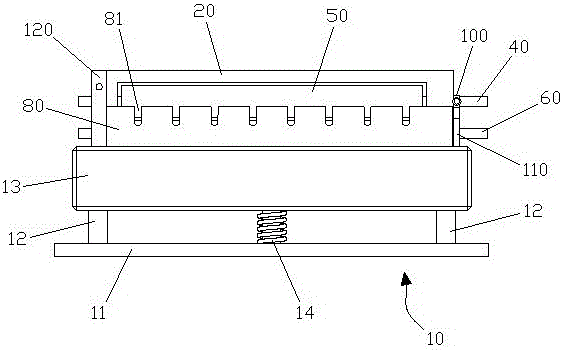

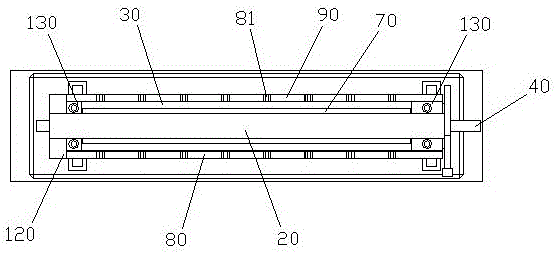

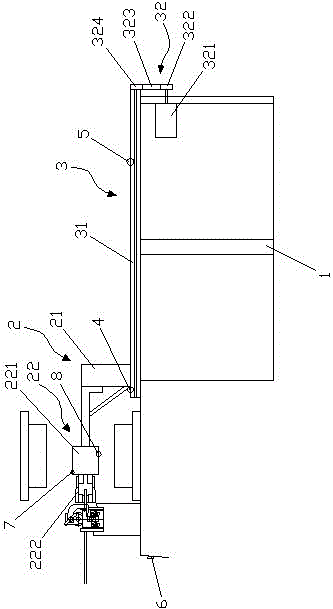

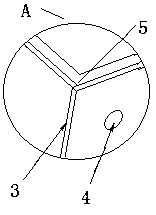

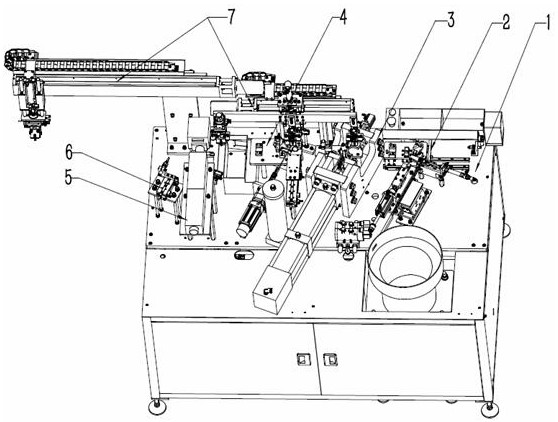

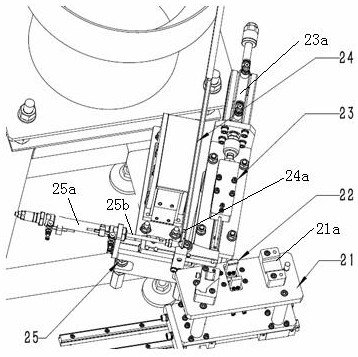

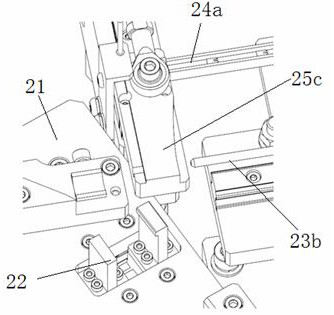

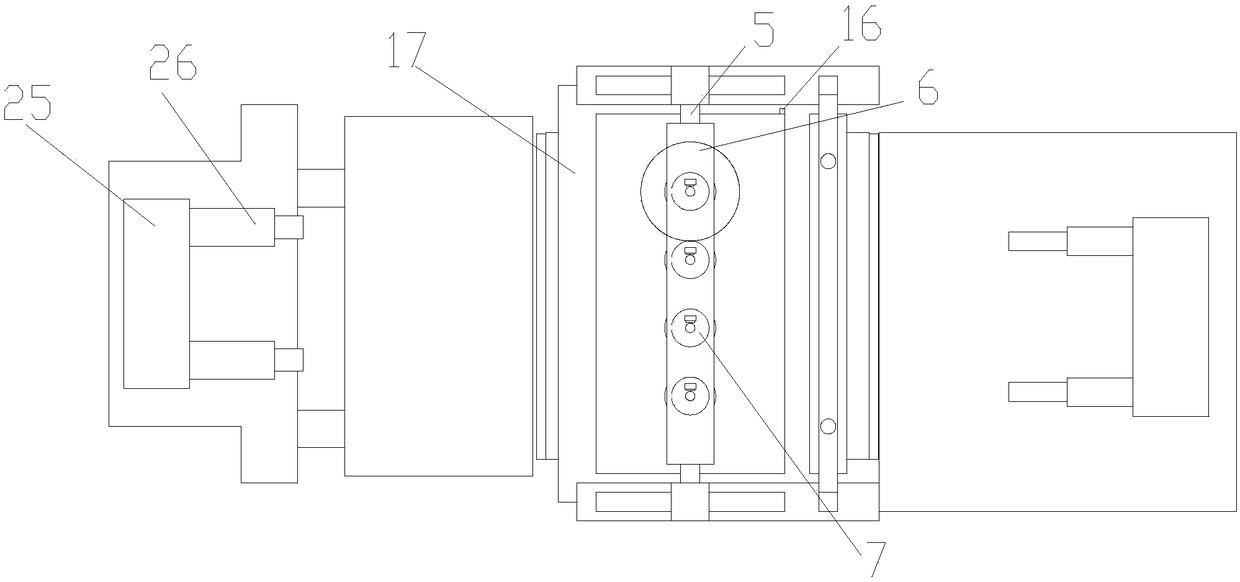

Intelligent rotary adsorption feeding and discharging device for anti-overflow cover plates of electric rice cooker covers

InactiveCN102581160AReduce manual work timeImprove loading and unloading efficiencyMetal-working feeding devicesPositioning devicesDischarge efficiencyPunching

The invention belongs to the technical field of automatic feeding and discharging devices, and relates to an intelligent rotary adsorption feeding and discharging device for anti-overflow cover plates of electric rice cooker covers. The intelligent rotary adsorption feeding and discharging device comprises six mechanical arms driven by a stepping motor, a telescopic cylinder, a limit contact switch and a sucker are mounted on each mechanical arm, and the six mechanical arms are connected with a controller and an air source. The intelligent rotary adsorption feeding and discharging device has the advantages that semi-finished products can be automatically placed into a punching machine, finished products are automatically placed into a finished product area, labor time is shortened, feeding and discharging efficiency is improved, space is saved and idle running is avoided by means of rotary operation, the height of a workpiece can be sensed by the limit contact switches so that a plurality of semi-finished products can be stacked together, and the intelligent rotary adsorption feeding and discharging device is simple and efficient by using the suckers for adsorption and U-shaped clamp grooves for clamping, and can adapt to the anti-overflow cover plates in different specifications only by adjusting the sizes of the U-shaped clamp grooves and the suckers, so that high universality is achieved.

Owner:CHINA JILIANG UNIV

Side polishing process for LCD planar target material

PendingCN111775030AImprove turnover rateReduce manual work timePolishing machinesGrinding machinesForeign matterEngineering

The invention discloses a side polishing process for an LCD planar target material. According to the side polishing process for the LCD planar target material, an IPA solution is applied to a scouringpad, and the side of the LCD planar target material is polished. The IPA solution is applied to the scouring pad and the side of the LCD planar target material is polished, so that the foreign matter, the copper rust and the non-target integrated substance on the side of the LCD planar target material are removed, the turnover rate of the target material polishing is improved, the manual operation time is reduced, the defective product is reduced, the roughness after polishing is stable, and the one-time pass rate is improved.

Owner:合肥江丰电子材料有限公司

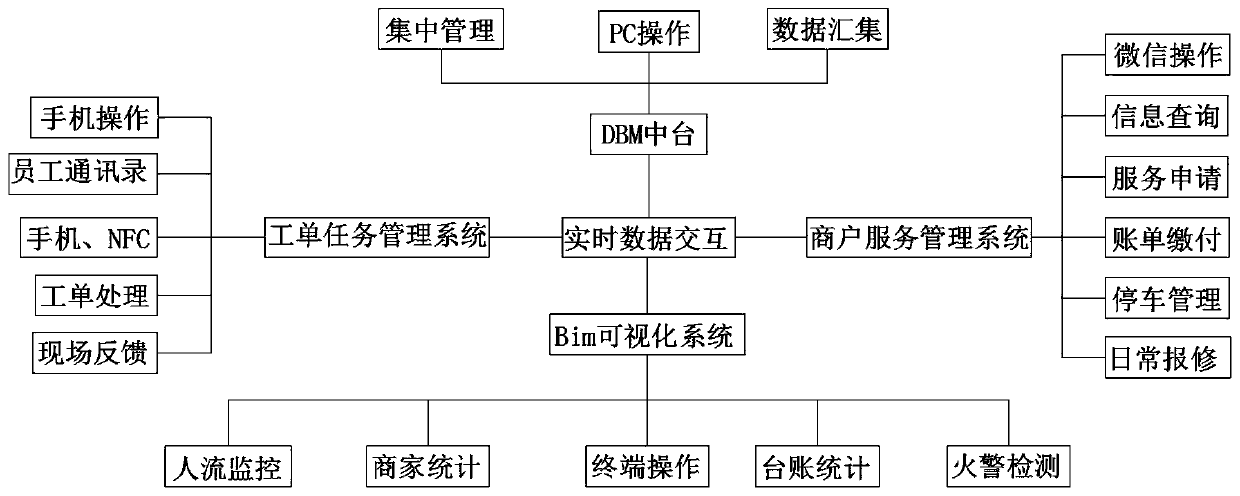

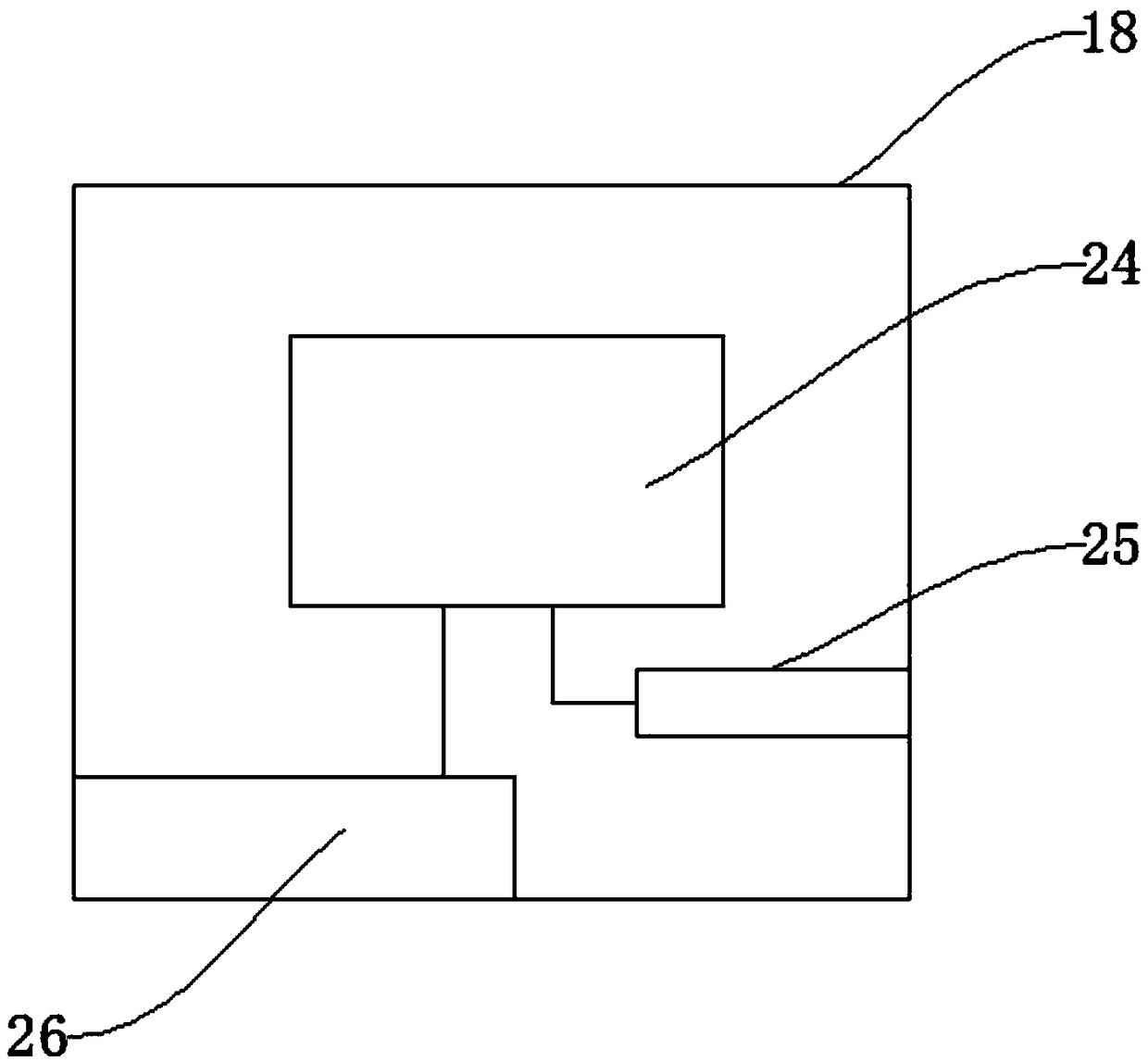

DBM intelligent building management tool

PendingCN110599368AEasy to viewSimple working processOffice automationResourcesManagement toolWork flow

The invention discloses a DBM intelligent building management tool which comprises the real-time data interaction, a DBM middle station, the PC operation, the centralized management, the data collection, a Bim visualization system, the terminal operation, the people flow monitoring, the merchant statistics, the standing book statistics and the fire alarm detection. According to the DBM intelligentbuilding management tool, the overall control is carried out through the real-time data interaction, and the intelligence is increased; the interconnection between the data and a building 3D model isestablished through the Bim visualization system, so that the related monitoring data can be checked more visually; the data transmission and analysis are carried out through the real-time data interaction; a work order task management system manages and publishes the work state of the employee in real time, so that the work flow of a property management layer is simplified, and the operation cost of enterprises is reduced; the merchants can perform relevant property query, payment projects and daily repair by themselves through a merchant service management system, so that the daily life ofthe merchants is facilitated; the work orders can be called at any time through the DBM middle platform, so that a large amount of manual work time is saved.

Owner:上海介谷科技有限公司

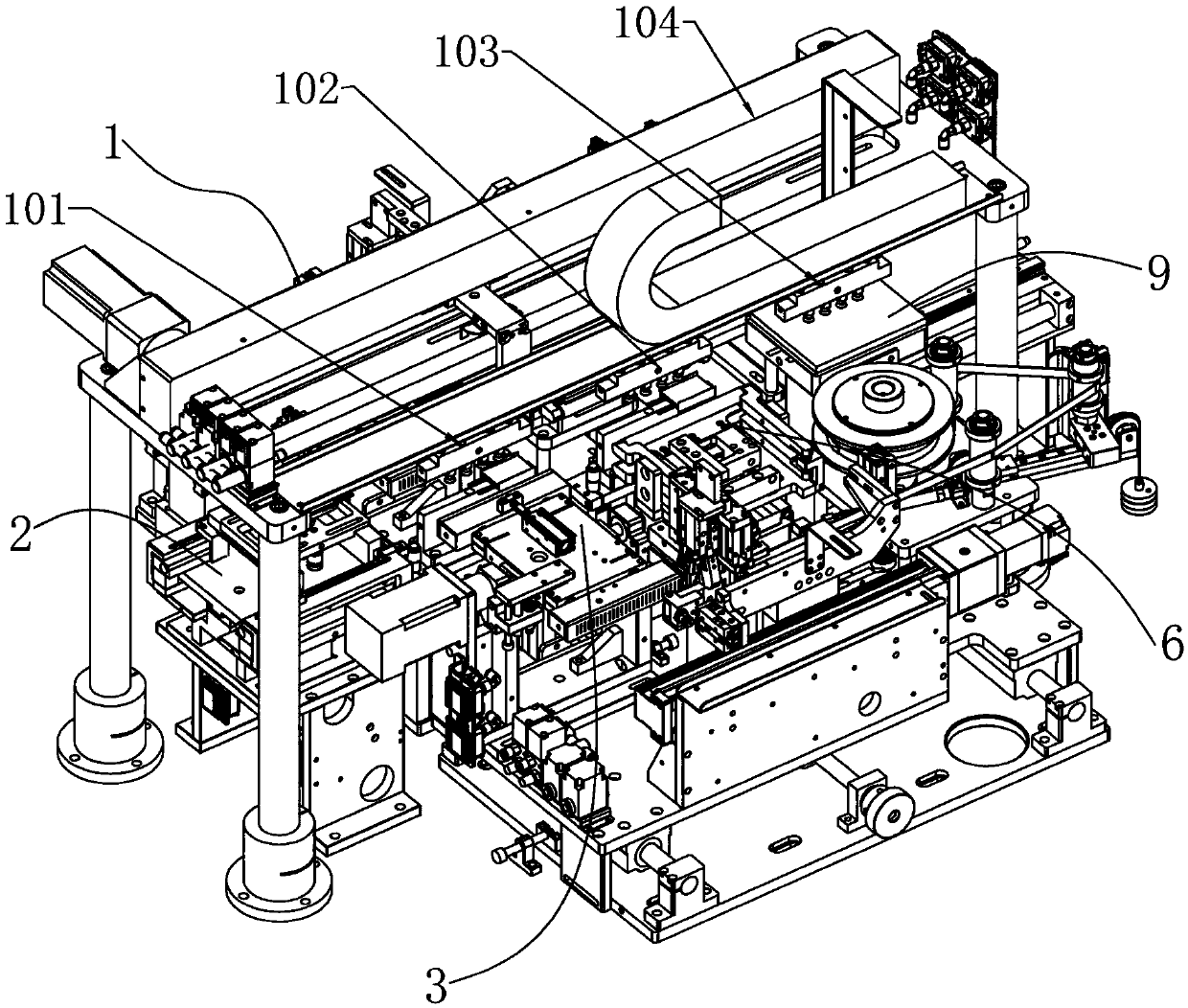

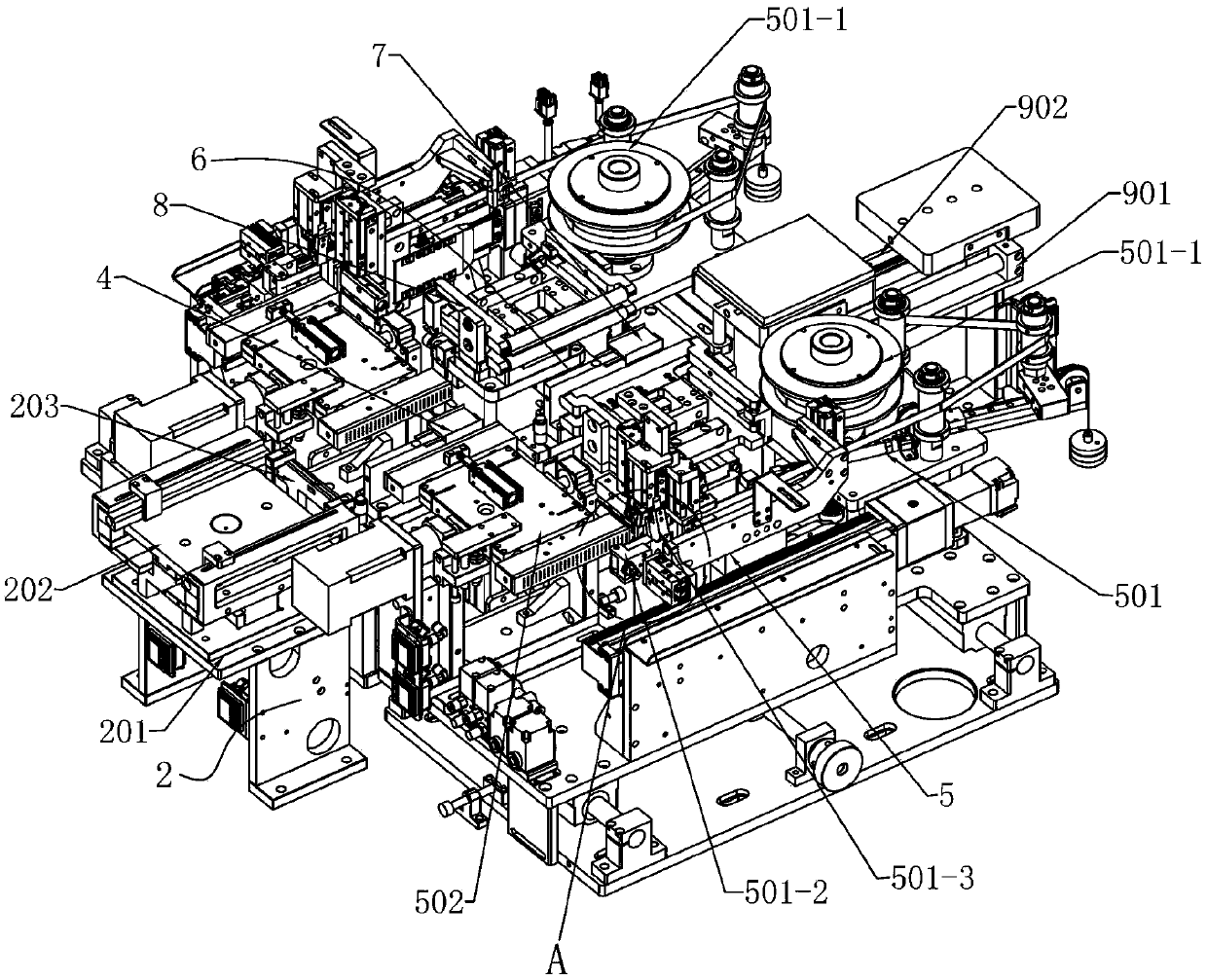

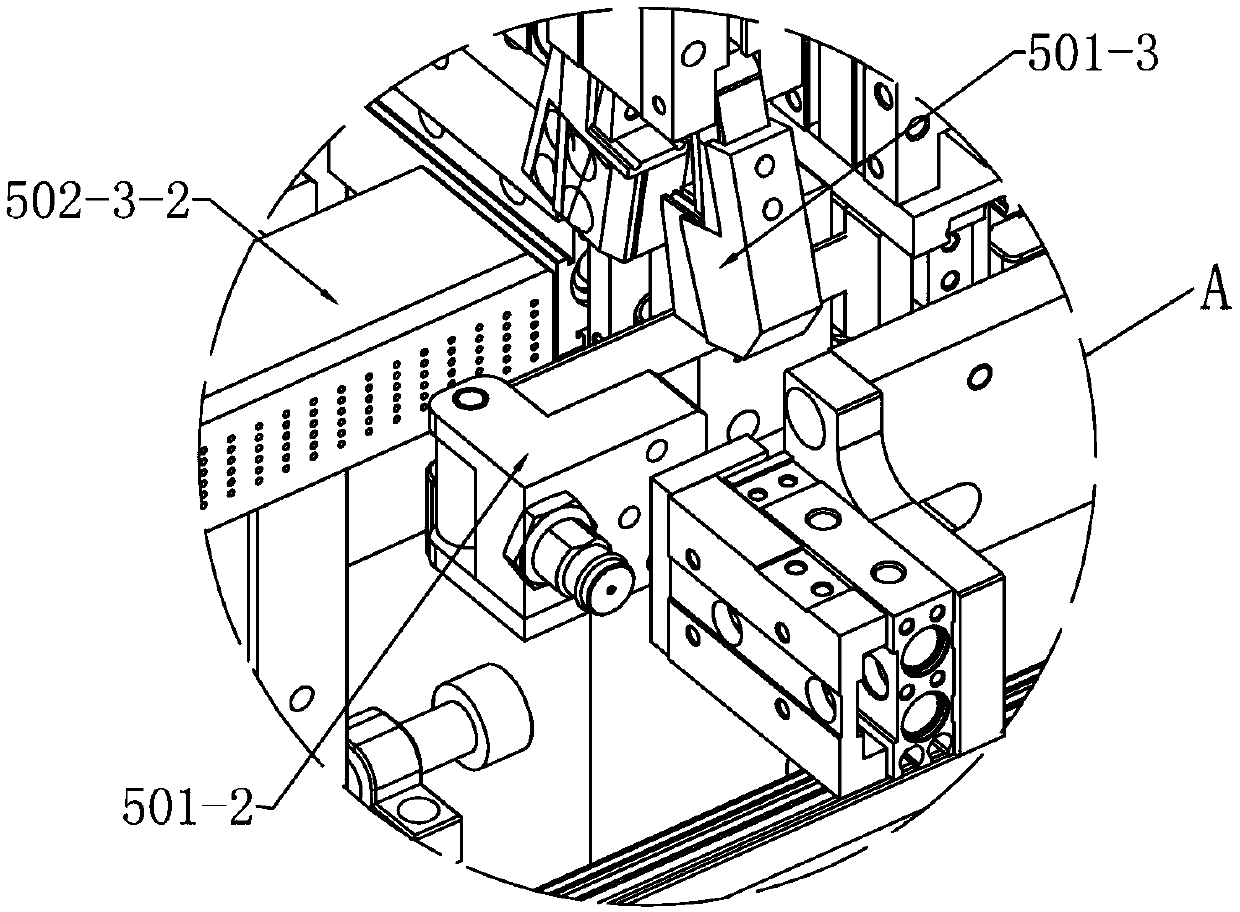

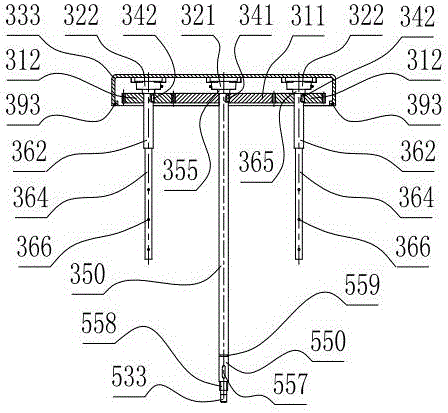

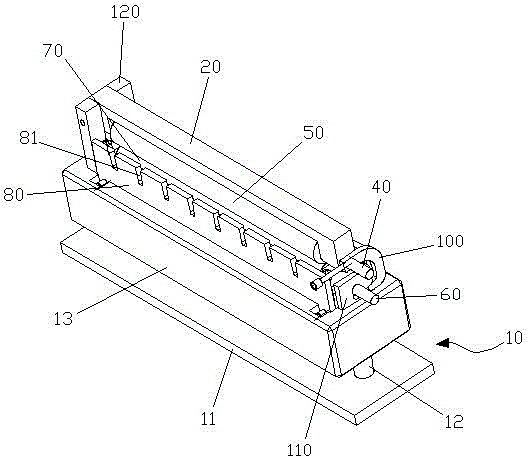

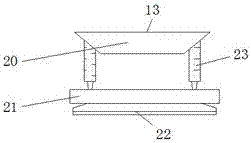

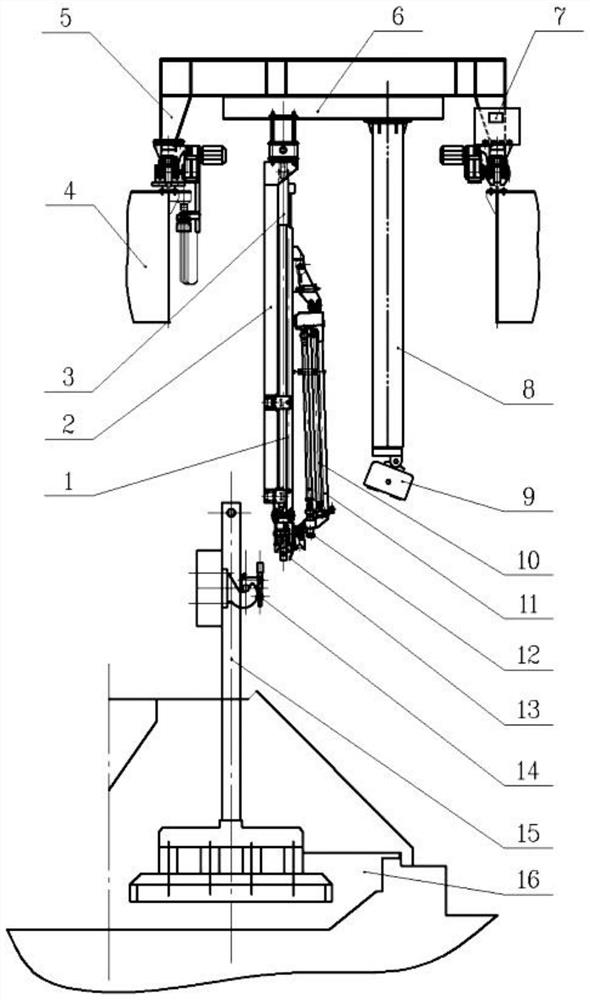

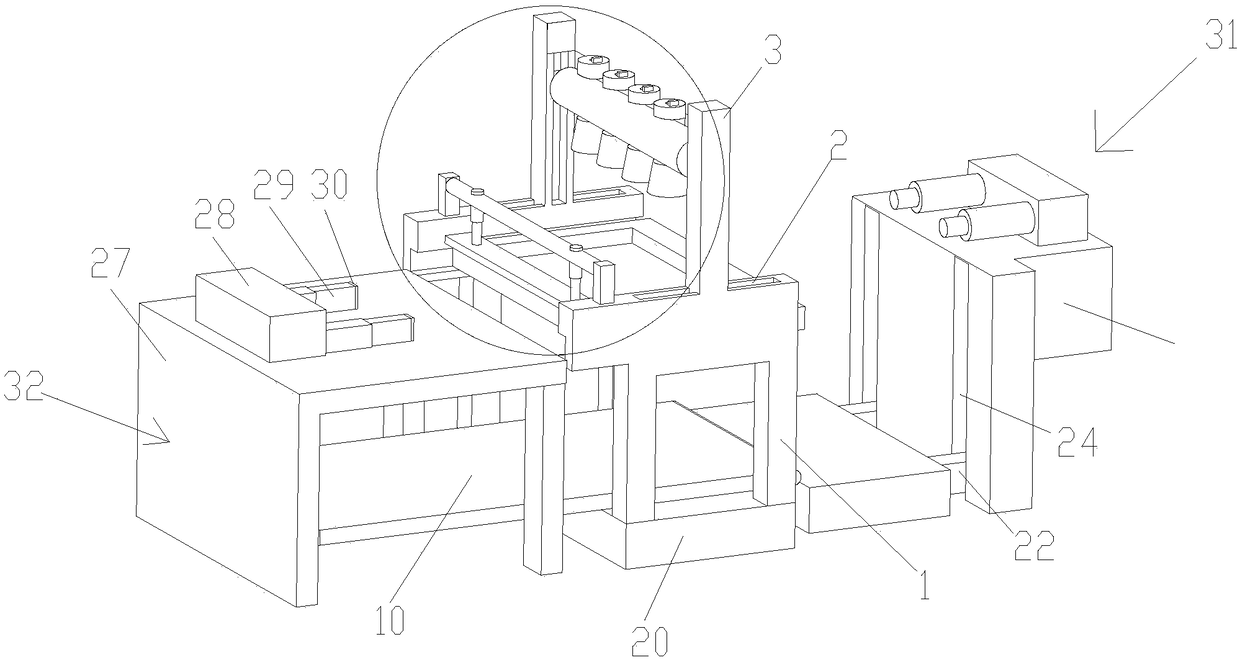

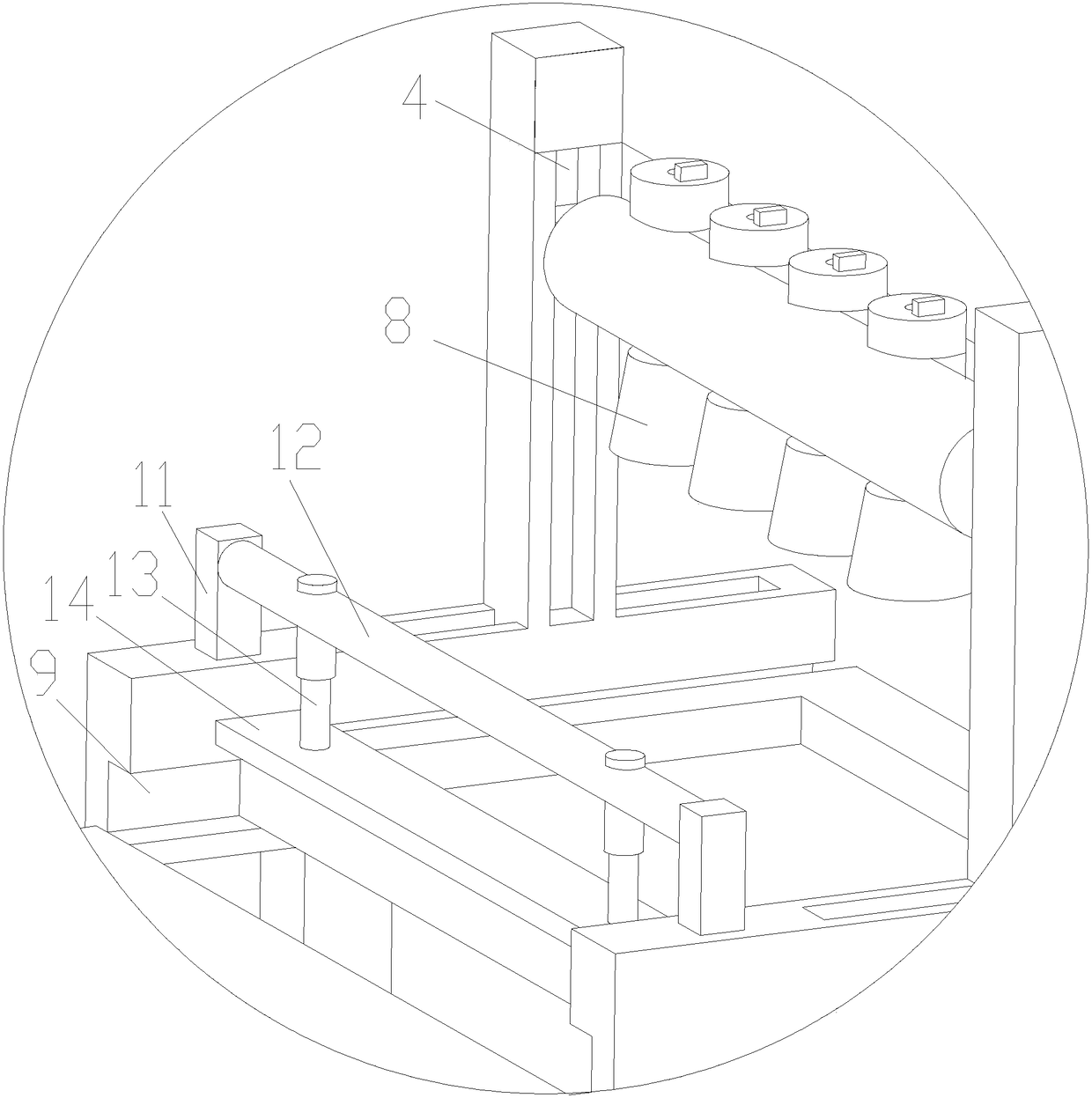

A double-side glue sticking device

PendingCN109103506ANovel structureHigh degree of automationFinal product manufactureElectrolyte accumulators manufactureEngineeringManipulator

The invention discloses a double-side glue sticking device, which comprises a moving unit, a shaping unit, a glue sticking unit, a pressing unit and a blanking unit. The shaping unit, the glue applying unit, the pressing unit and the blanking unit are arranged side by side in sequence, and the moving unit spans the shaping unit, the glue applying unit, the pressing unit and the blanking unit and is above the shaping unit, the glue applying unit and the blanking unit; The moving unit comprises a support frame, a first manipulator, a second manipulator and a third manipulator, the first manipulator, the second manipulator and the third manipulator being arranged side by side on the support frame in this order, the support frame spanning the shaping unit, the glue applying unit, the pressingunit and the blanking unit. Compared with the prior art, the double-side glue sticking device provided by the invention has the advantages of novel structure, high automation degree, simultaneously carrying out the double-side glue sticking and pressing, reducing the manual operation time, reducing the labor intensity of workers, high stability, improving the production efficiency and ensuring theproduct quality.

Owner:东莞市爱康智能技术有限公司

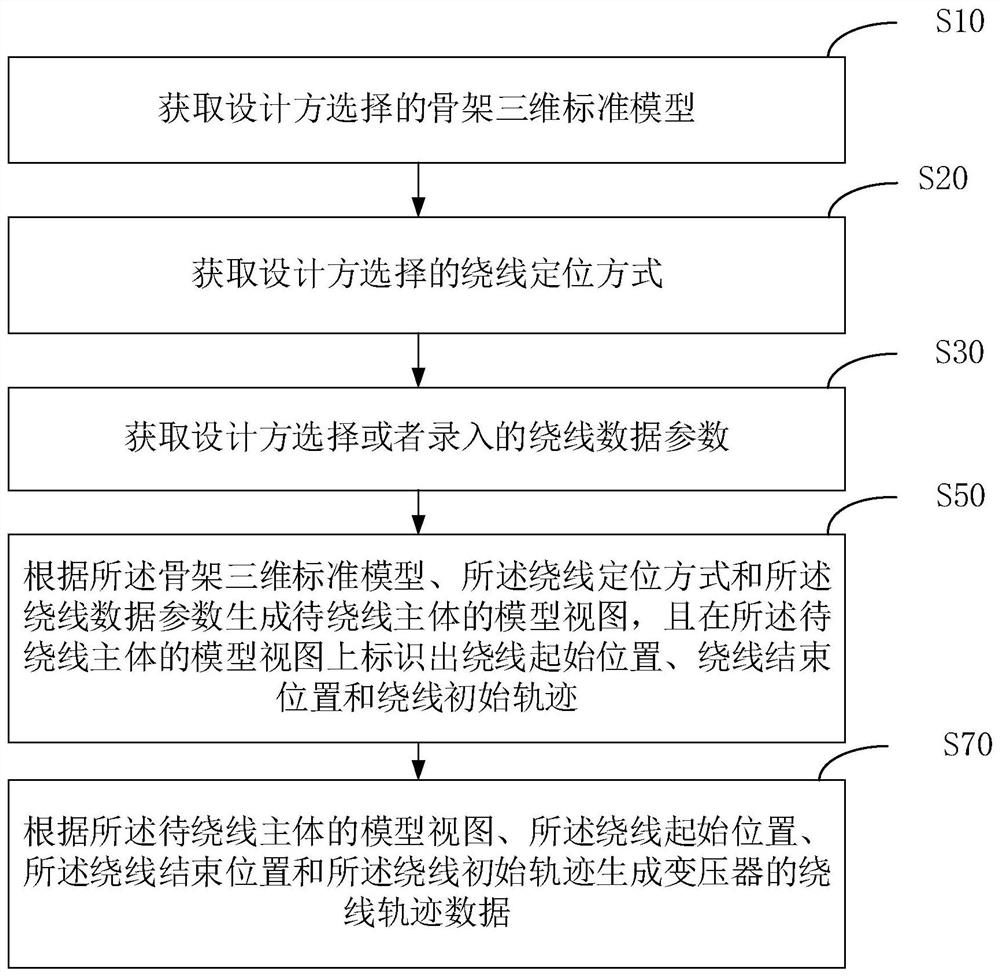

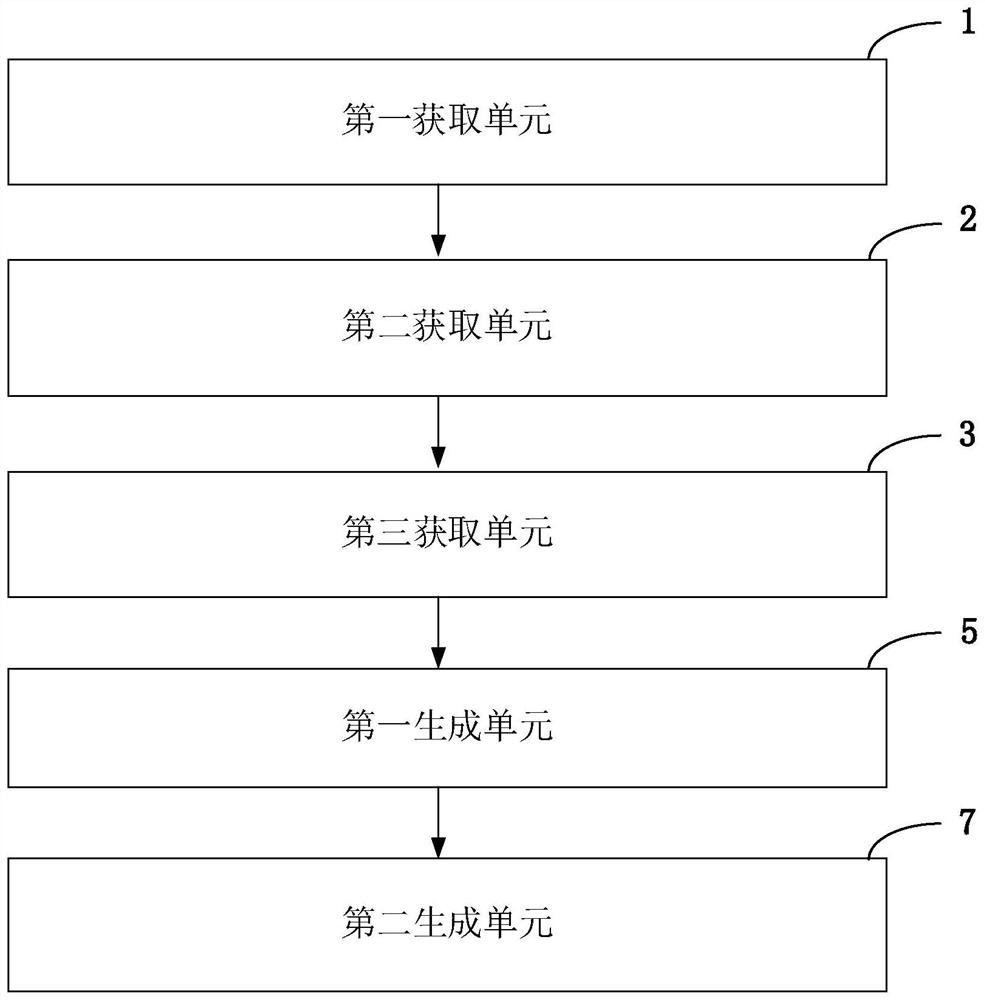

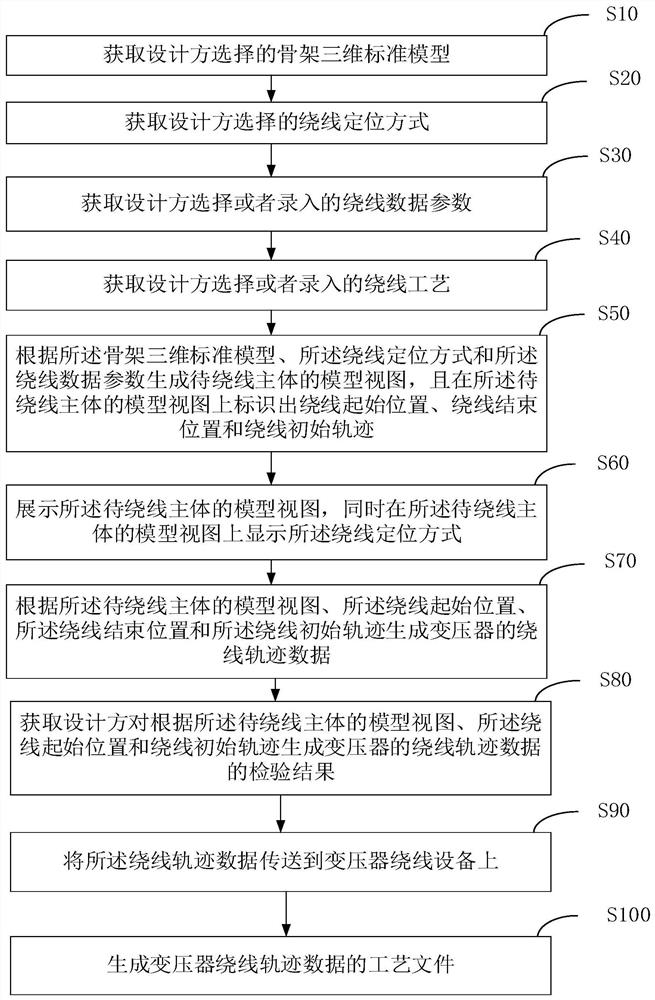

Design method for winding track of transformer

PendingCN113593892AImprove the efficiency of winding workAutomate operationsGeometric CADDesign optimisation/simulationWinding machineControl engineering

The invention relates to the technical field of transformer design, and in particular relates to a design method for a winding track of a transformer. The method comprises the following steps: acquiring a skeleton three-dimensional standard model selected by a designer; obtaining a winding positioning mode selected by the designer; obtaining winding data parameters selected or input by the designer; generating a model view of a to-be-wound main body according to the skeleton three-dimensional standard model, the winding positioning mode and the winding data parameters, and marking a winding starting position, a winding ending position and a winding initial track on the model view of the to-be-wound main body; according to the model view of the to-be-wound main body, the winding starting position, the winding ending position and the winding initial track, generating winding track data of the transformer, and inputting the winding track data into a winding machine, so that automatic operation of the transformer winding machine can be realized, the manual operation time is shortened, and the winding operation efficiency of the transformer is greatly improved.

Owner:SHENZHEN DABO IND CO LTD

Method for improving plane smooth degree of wood mold

The invention relates to the field of wood mold casting, in particular to a method for improving the plane smooth degree of a wood mold. The method comprises the following steps that 1, the mold is designed, wherein software is used for designing a wood mold structure, the size of all plane portions of the wood mold is reduced by 1 mm, and all the plane portions are used for installing aluminum plates; 2, the mold is manufactured, wherein according to the wood mold structure, wood is used for machining and manufacturing the mold; 3, the aluminum plates are bonded, wherein a plate shearing machine is used for shearing the aluminum plates, and the aluminum plates are bonded to all the planes of the wood mold; 4, the edges of the aluminum plates are reinforced, wherein the edge portions of the aluminum plates are reinforced by riveting rivets, and cracking is prevented; and 5 the surface of the mold is treated, wherein the connecting portions of the aluminum plates and other faces are sanded and polished. By installing the aluminum plates on all the surfaces of the wood mold, the wood mold plane smooth degree is improved, the situation that due to the fact that sand adheres to the wood mold, the wood mold is damaged is prevented, drawing performance of the wood mold can be reinforced, the surface quality of sand cores is improved, few mold releasing agents are used, manual operation time can be shortened, and the working efficiency is improved.

Owner:KOCEL EQUIP

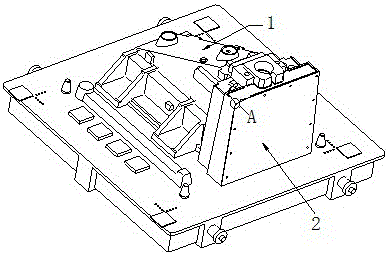

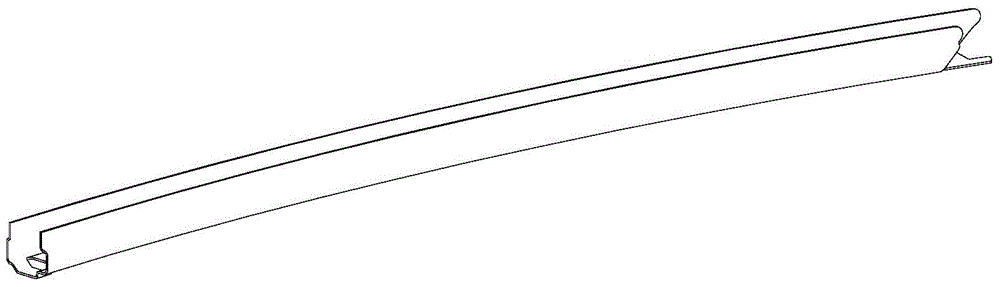

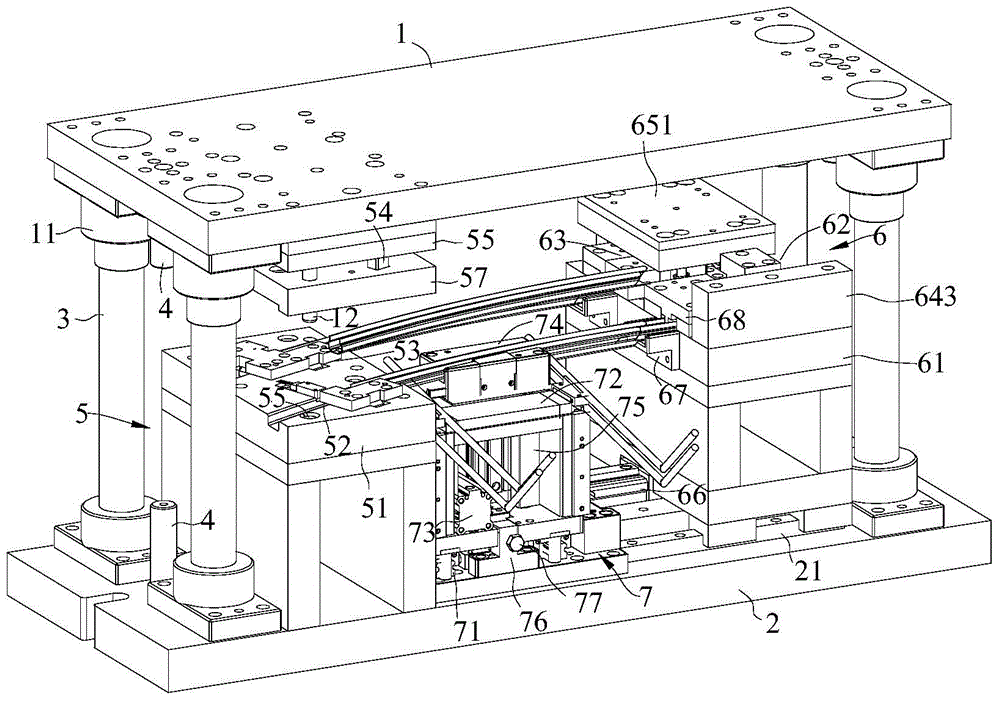

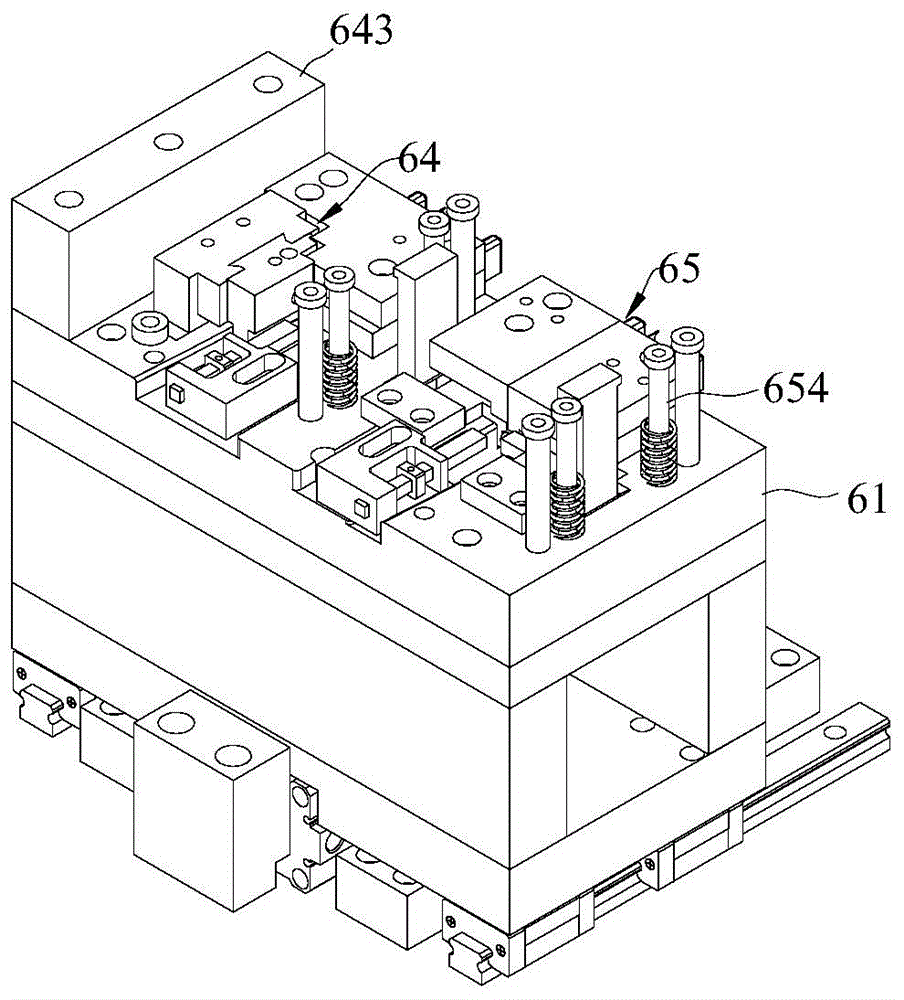

Punching die for door and window glass guide groove

The invention discloses a punching die for a door and window glass guide groove. The punching die comprises an upper die plate, a lower die plate, guide posts, a left side punching mechanism, a right side punching mechanism and a movable clamping claw; the left side punching mechanism comprises a left side punching base with a left side first punching position and a left side second punching position, a plunger chip is installed on the upper die plate, and the right side punching mechanism comprises a right side punching base with a right side first punching position, a right side second punching position, a right side first plunger chip mechanism and a right side second plunger chip mechanism; the left side first punching position and the right side first punching position form a first station, and the left side second punching position and the right side second punching position form a second station. Punching of the two stations is achieved on one die, the two stations share one oil press, the space occupancy rate is small, the punching die is convenient and fast to operate, manual operation time is shortened, the product quality is promoted, the tatk is accelerated, the product qualification precision is met, and defective products are eradicated.

Owner:GUANGZHOU MINTH AUTOMOBILE PARTS CO LTD

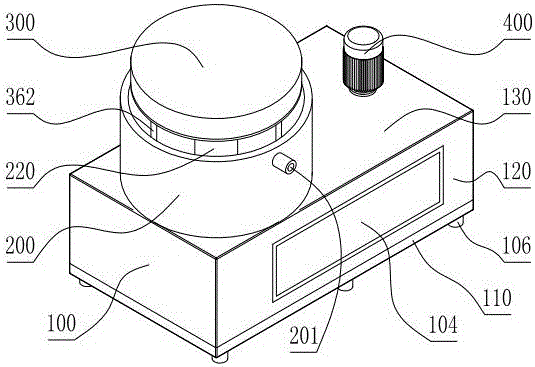

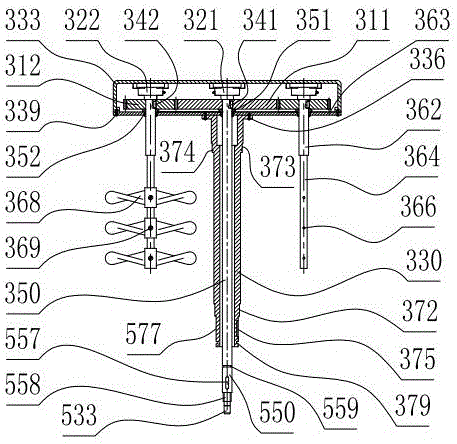

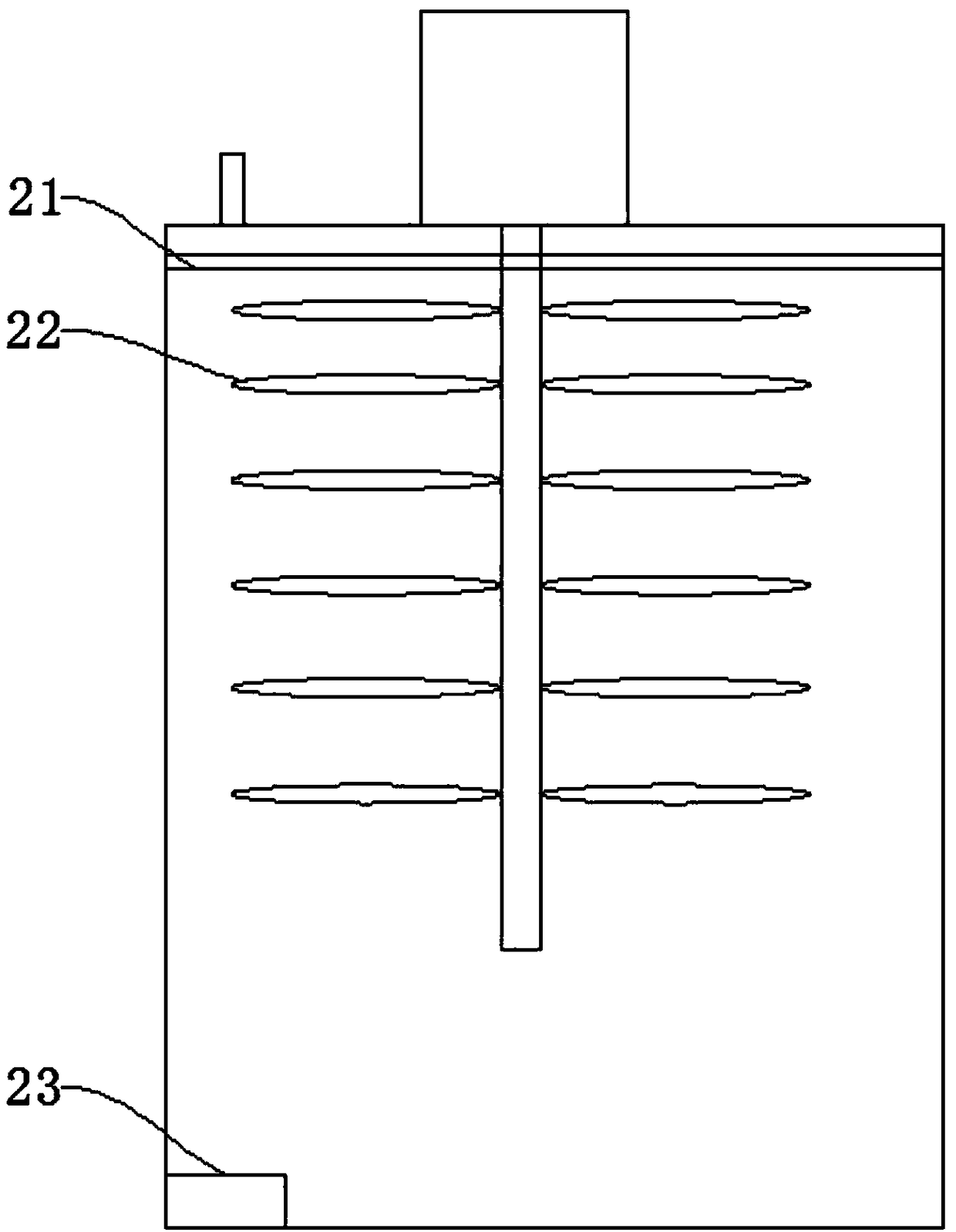

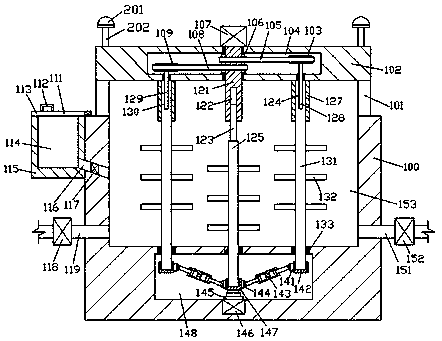

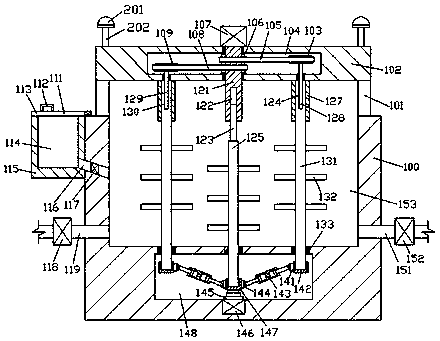

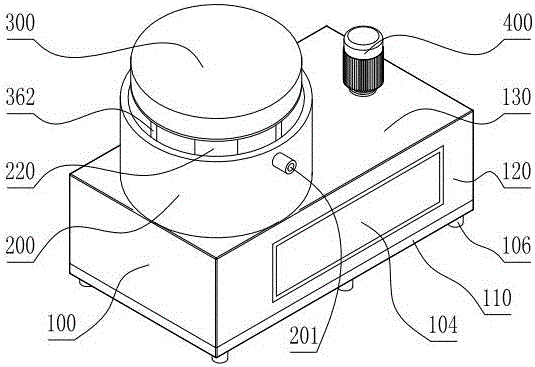

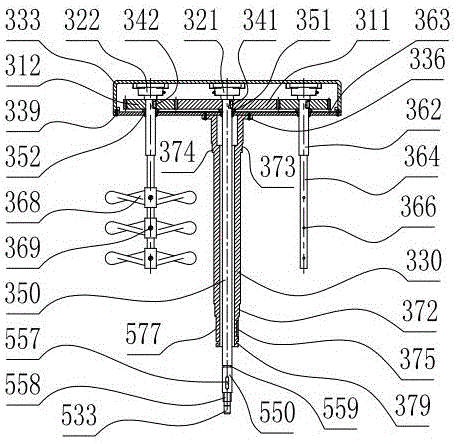

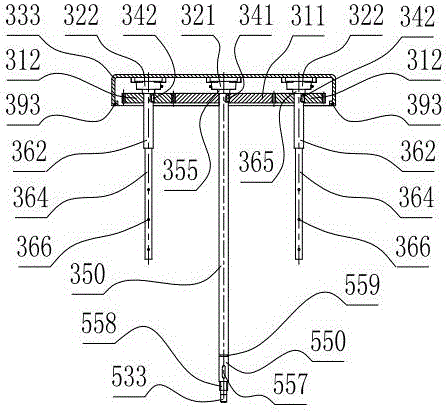

Sealing-free combined rotating ceramic paddle paper pulp stirring equipment

InactiveCN106732067AReduce processing timeSimple and safe operationRotary stirring mixersTransportation and packagingPulp and paper industryCorrosion

The invention relates to the technical field of paper making mechanical equipment, and discloses sealing-free combined rotating ceramic paddle paper pulp stirring equipment. The sealing-free combined rotating ceramic paddle paper pulp stirring equipment comprises a base part, a paper pulp stirring pond, a combined rotating mechanism and a motor; as improved, the torque between a rotation driving belt wheel and a rotation driven belt wheel is transmitted by a rotation transmission belt; the torque between the rotation driven belt wheel and a driven rotating shaft is transmitted by a driven shaft lower key; the torque between a central gear and the driven rotating shaft is transmitted by a driven shaft upper key; the central gear and a rotation gear are mutually meshed; the torque between the rotation gear and a rotation paddle shaft is transmitted by a free rotating key; a rotation square shaft is arranged at the lower section of the rotation paddle shaft; the rotation square shaft is provided with stirring paddles; the stirring paddles are positioned above a pulp pond bottom plate. By arranging a revolution transmission belt and a rotation transmission belt at the inner part of the base support, the operation is convenient and safe; a pulp pond central cylinder is arranged in the paper pulp stirring pond, so that a revolution driving belt wheel and the rotation driving belt wheel which are used for power transmission are thoroughly isolated from paper pulp, no corrosion is caused, and sealing is not needed.

Owner:温州立意机电科技有限公司

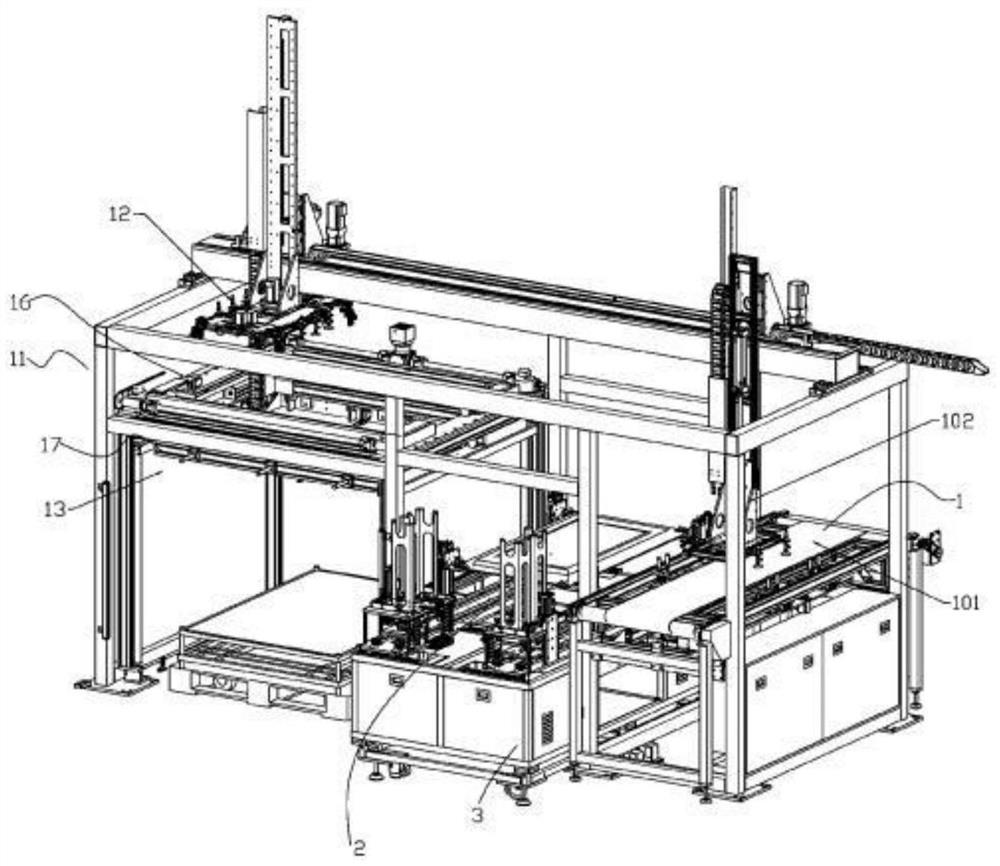

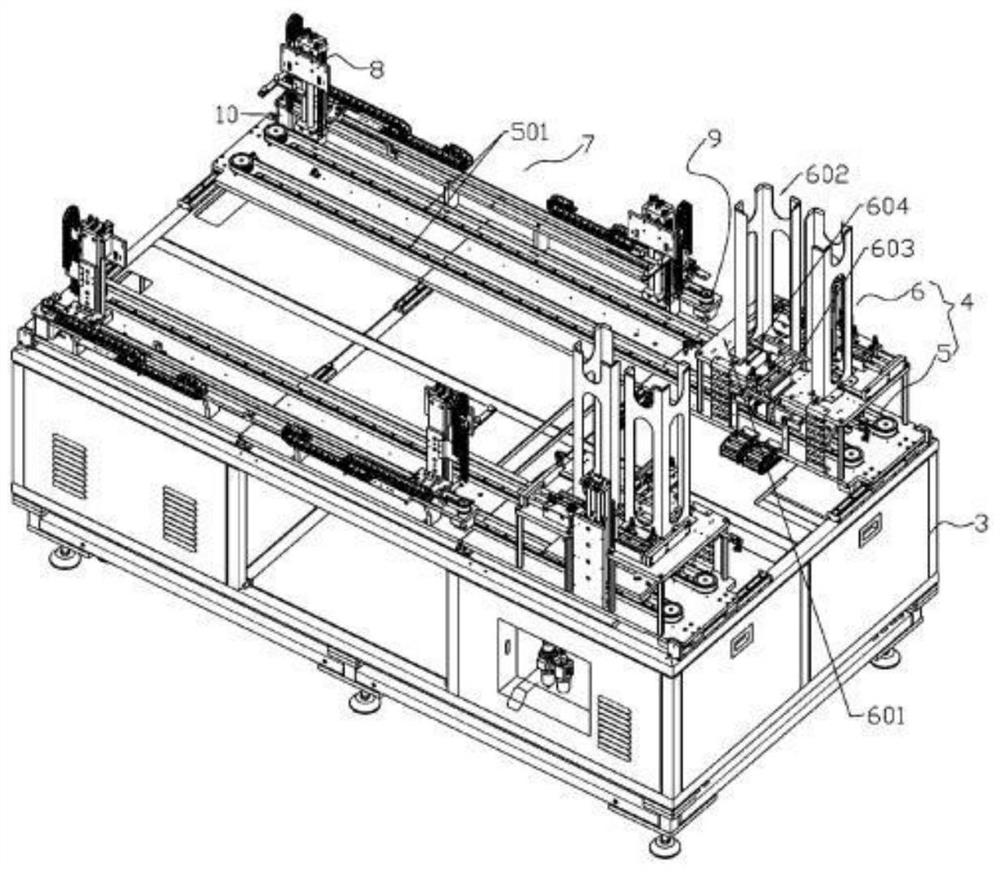

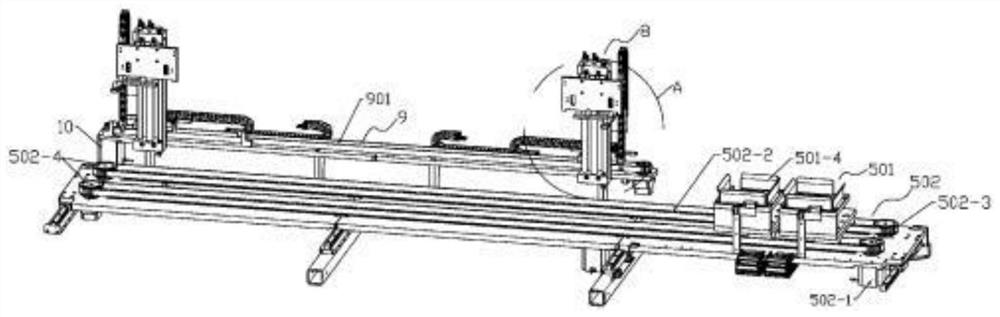

Automatic packaging system for television backboards

PendingCN112744379AHigh degree of mechanizationNovel structureIndividual articlesWorkbenchManual handling

An automatic packaging system for television backboards comprises an unpacking workbench and a corner connector assembling assembly, wherein the television backboards on the unpacking workbench are manually unpacked, the television backboards are manually stacked on a front conveying assembly, the television backboards are conveyed one by one through the front conveying assembly, and the corner connector assembling assembly is used for automatically assembling corner connectors of the television backboards. The system is high in mechanization degree, novel in structure and high in practicability; and the corner connectors can be accurately and correspondingly placed at the four corners of the television backboards, and then the television backboards with the corner connectors placed are transferred to a tray of a discharging and stacking unit through a discharging mechanical arm. According to the automatic packaging system for the television backboards, the automation degree is high, the manual operation time is shortened, the burden of operators is reduced, and the working efficiency is improved; and meanwhile, multiple operation accidents occurring in manual operation can be avoided, potential safety hazards are reduced, and the safe operation environment is ensured.

Owner:广东凯宝机器人科技有限公司

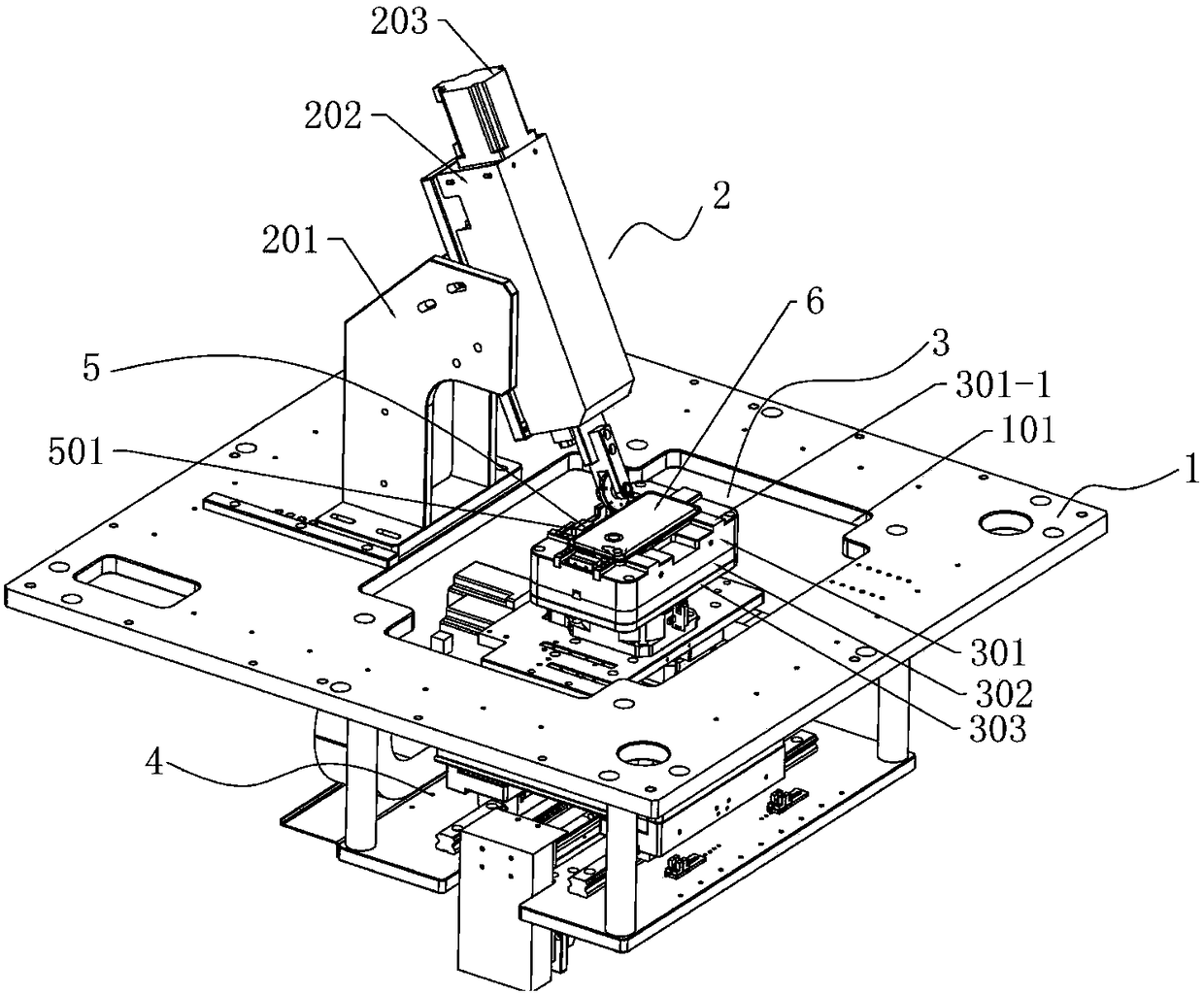

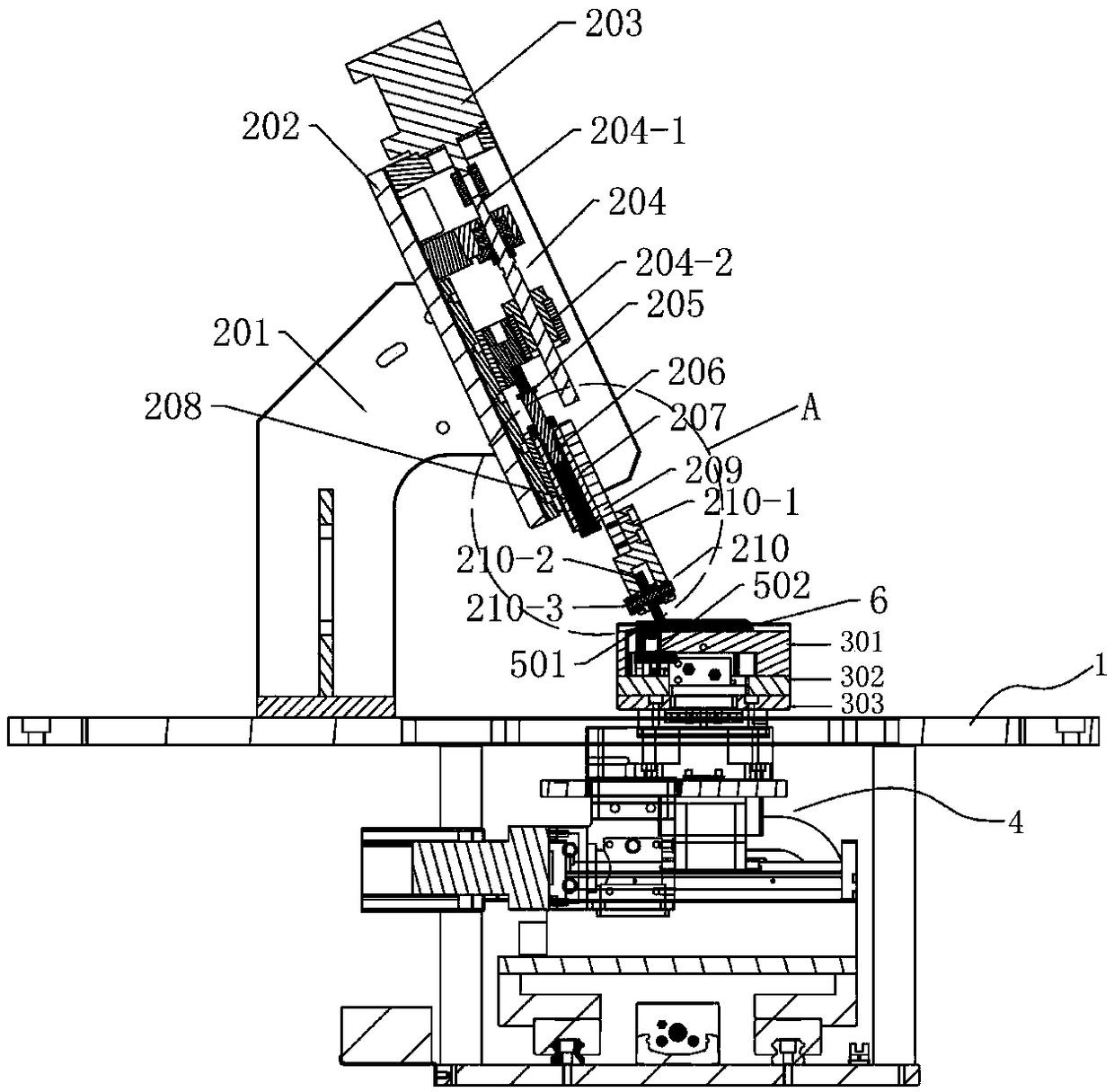

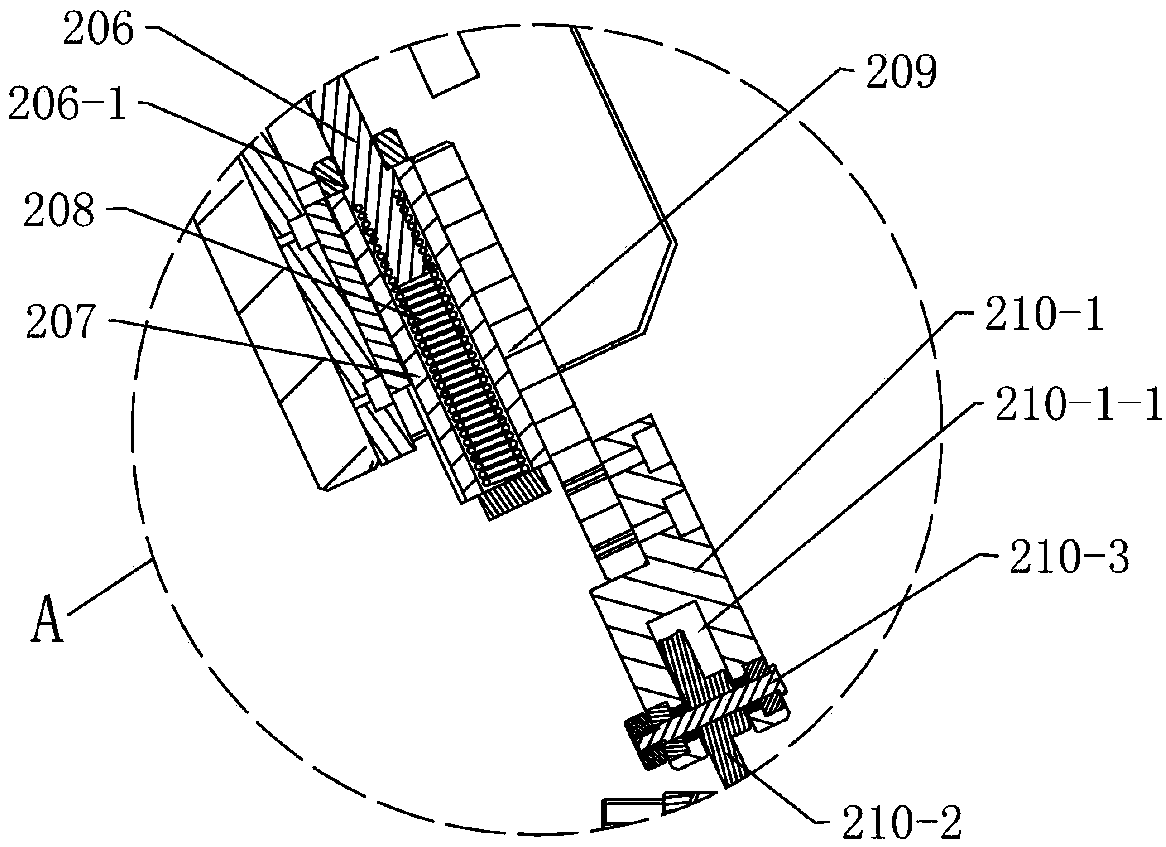

Rolling device

The invention discloses a rolling device. The device comprises a man-machine control system, a base, a rolling mechanism, a carrying table and a carrying table drive device. A mounting hole is formedin the middle of the base, the carrying table is arranged in the mounting hole of the base, the rolling mechanism is fixed to the position above the carrying table and is fixed to one side of the mounting hole, the rolling mechanism is arranged above the carrying table in an inclined manner, and the carrying table drive device is arranged below the carrying table and is in drive connection with the carrying table. Compared with the prior art, the rolling device is novel in structure, high in automation degree and capable of shortening the manual work time, defects of pure manual and jig assembling is solved, labor intensity of a worker is reduced, and production efficiency is improved. Through a pressure sensor and a pressure spring, the poor instant pressure floating of a roller to a mobile phone rear cover can be avoided, rolling is carried out along the edge of a mobile phone, the stress of the mobile phone rear cover is uniform, damage due to too large pressure is avoided, and product quality is ensured.

Owner:东莞市爱康智能技术有限公司

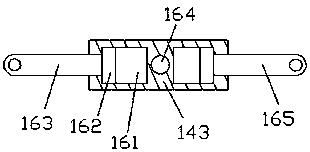

Trailer card cycloidal tool

The invention discloses a trailer card cycloidal tool. The trailer card cycloidal tool comprises a base, and an upper fixture and a lower fixture arranged on the base; a first groove is formed in the upper fixture; an upper bearing roller is rotationally arranged in the first groove through a first bolt; a second groove is formed in the lower fixture; a lower bearing roller is rotationally arranged in the second groove through a second bolt; a limiting space for limiting wires to swing up and down is formed between the upper bearing roller and the lower bearing roller; a front plate and a back plate are respectively arranged on the front and back two sides of the lower fixture; multiple clamping grooves arranged side by side and corresponding one to one are formed in the front plate and the back plate; and the clamping grooves are corresponding to the limiting space for limiting the wires to shake left and right. The trailer card cycloidal tool can quickly place and fix the wires in injection molding of power supply wire trailer cards, can limit the wires to shake up and down and to swing left and right through the upper bearing roller, the lower bearing roller and the clamping grooves, is stable in placement, can once place multiple power supply wires, is high in working efficiency, and effectively shortens the manual operation time.

Owner:深圳市国信达科技股份有限公司

Automatic overturning device of stamping production line

InactiveCN109290461ASimple structurePracticalMetal-working feeding devicesPositioning devicesProduction lineTransfer mechanism

The invention discloses an automatic overturning device of a stamping production line. The automatic overturning device of the stamping production line comprises a base, a transferring mechanism, an overturning mechanism, a lifting mechanism and a suction mechanism. The transferring mechanism and the overturning mechanism are arranged on the upper side of the base. The lifting mechanism is fixedlyarranged below the transferring mechanism and located on the front side of the base. The overturning mechanism is connected with the transferring mechanism in a sliding manner. The suction mechanismis arranged on the front side of the overturning mechanism and fixedly connected with the overturning mechanism. Compared with the prior art, the automatic overturning device of the stamping production line is simple in structure and high in practicability, shortens the time of manual operation, improves the production efficiency of the production line and can ensure the production stability of the production line.

Owner:TRANS AUTOMATION TECH CO LTD

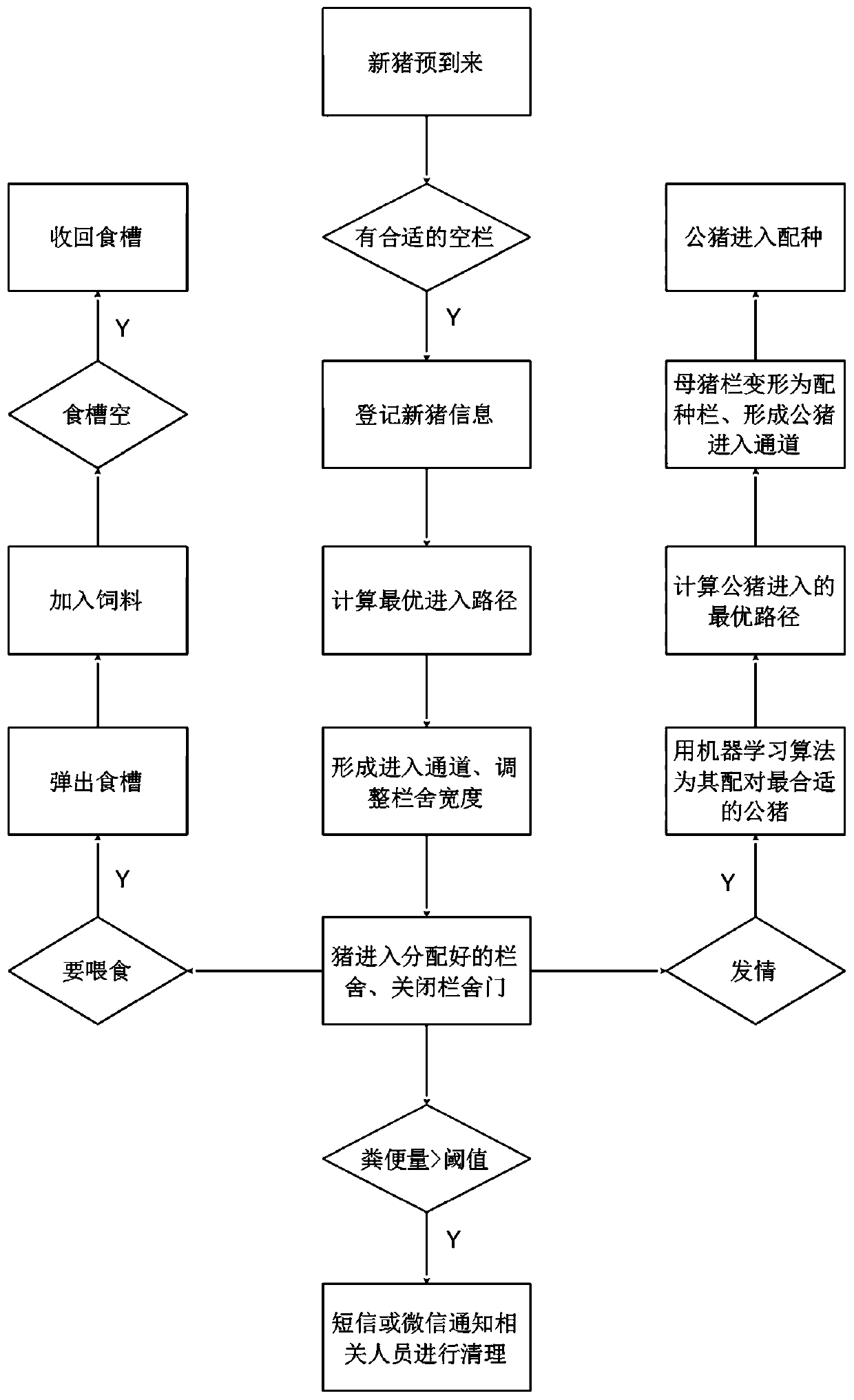

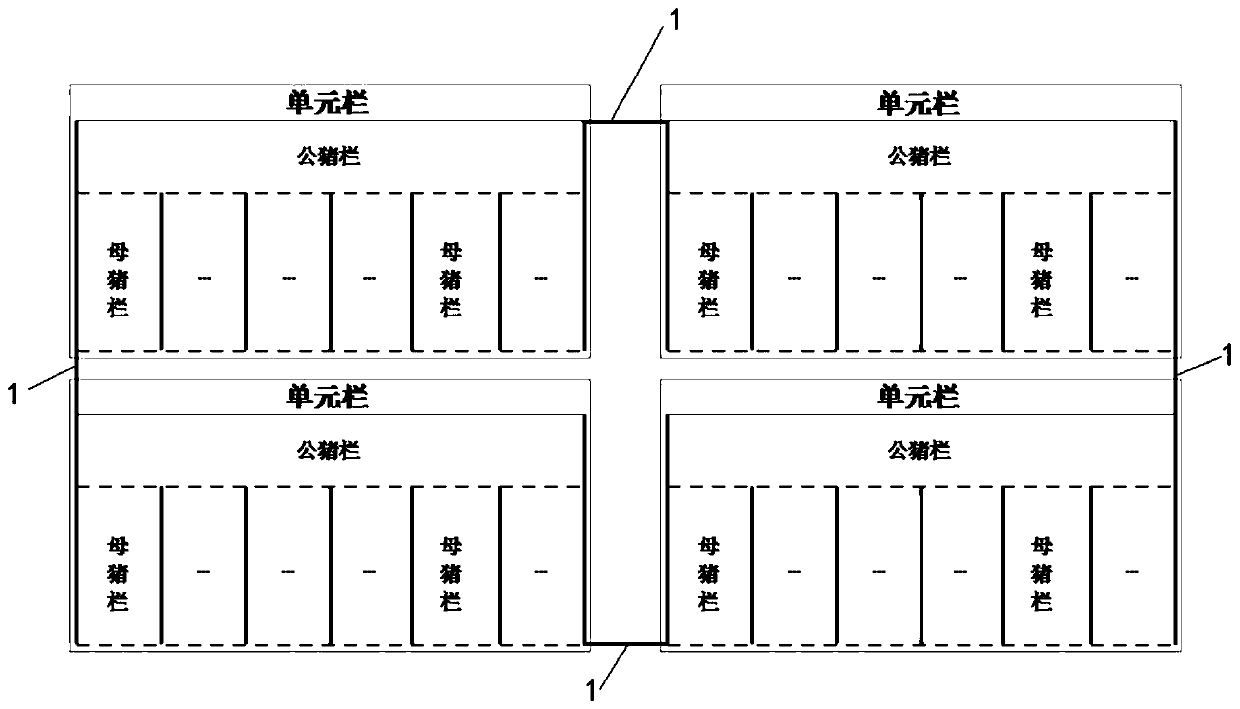

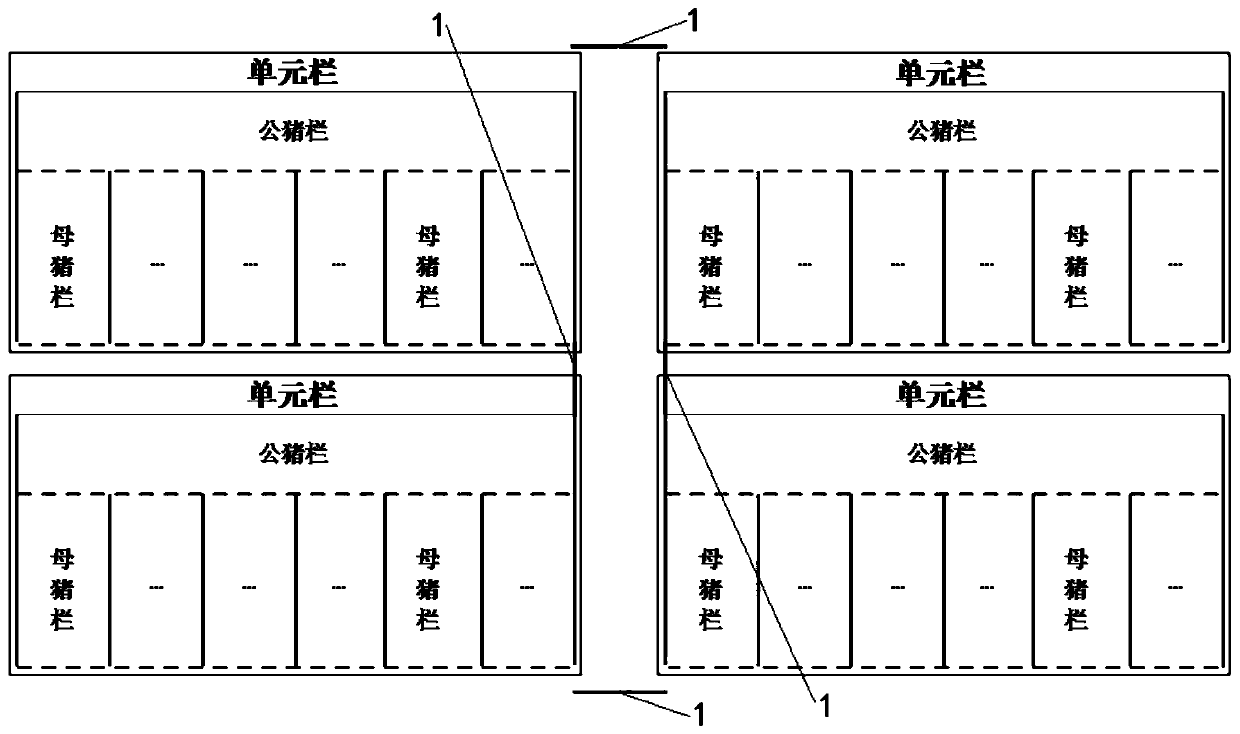

Application method for intelligent hog house

ActiveCN111034630AReduce manual work timeImprove efficiencyAnimal housingClosed circuit television systemsAnimal scienceEngineering

The invention provides an application method for an intelligent hog house. The intelligent hog house comprises a boar pen and one or more sow pens which constitute a unit pen, wherein each sow pen iscomposed of a movable side pen, a front door and a rear door; the front door of each sow pen is used for separate the boar pen from a sow pen; a channel is arranged at the outer sides of the side fences of the sow fences and is connected with the boar fence and the rear doors of the sow fences; movable enclosing walls are arranged among more than one unit pens; the intelligent hog house also comprises a camera device; when a new pig needs to be allocated to the hog house, information of the new pig is collected; an empty pen is searched in the intelligent hog house through the camera device; an optimal path is generated between the position of the new pig and the empty pen according to acquired information through a machine learning algorithm; a to-be-moved pen, doors and movable enclosingwalls between unit fences are input for operation to form a channel, so the new pig enters the empty pen; and the doors are closed, and the pen and the movable enclosing walls are reset. The application method provided by the invention greatly increases the working efficiency of new pigs to enter the hog house.

Owner:MIAOZHEN INFORMATION TECH CO LTD

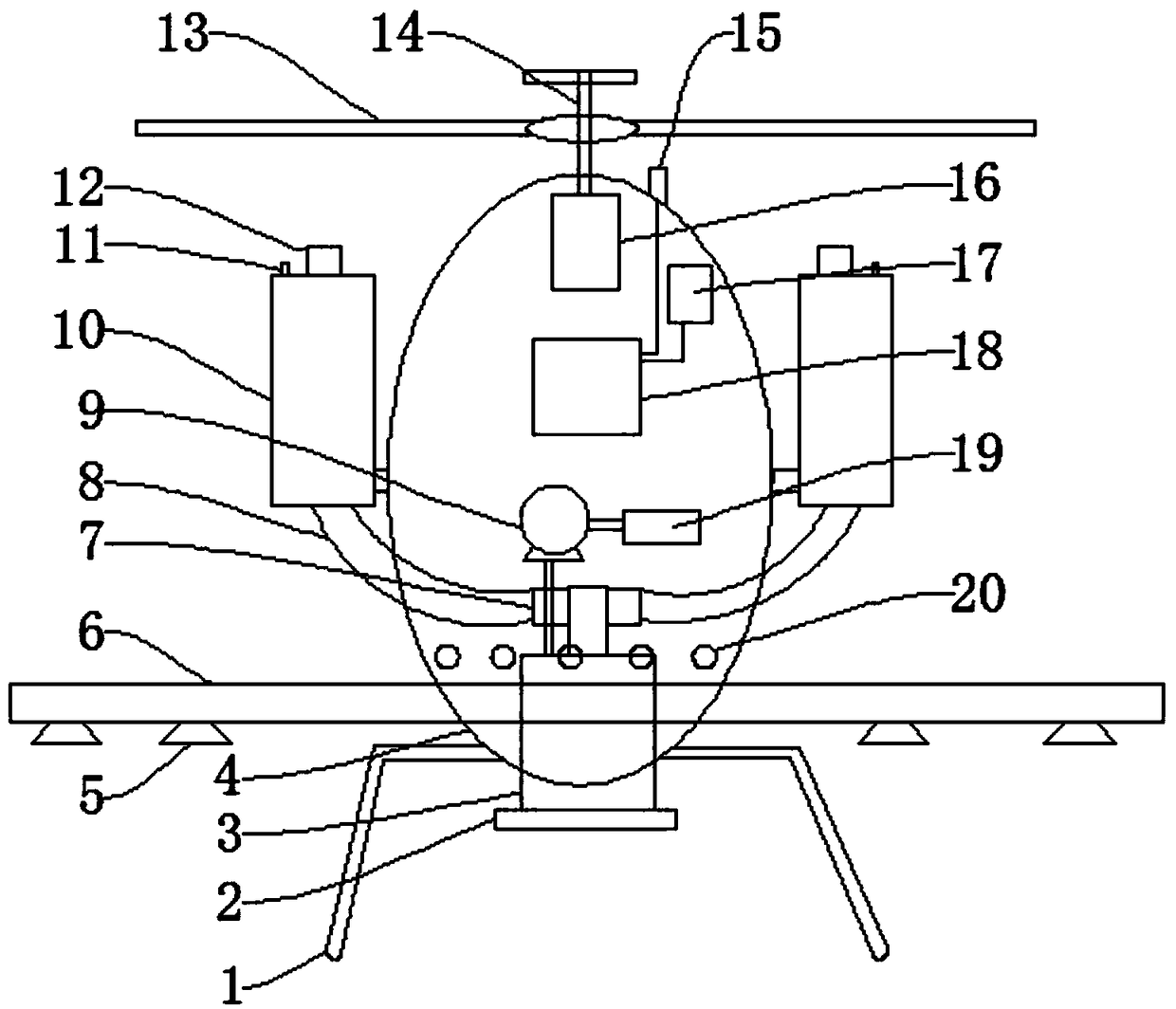

Unmanned aerial vehicle medicament spraying device for olive plantation and application method thereof

InactiveCN109178317AReduce manual work timeAircraft componentsRotary stirring mixersFixed frameEngineering

The invention discloses an unmanned aerial vehicle (UAV) medicament spraying device for olive plantation and an application method thereof, including UAV supports, a bottom lining, a UAV main body, anelectromagnetic flow valve, a liquid medicine container, wherein the bottom lining is arranged between the UAV supports; an auxiliary medicine box is arranged above the bottom lining; the UAV main body is arranged above the auxiliary medicine box; a sprayer fixing bracket is arranged at the bottom of the UAV main body; a liquid medicine sprayer is arranged below the sprayer fixing frame; two sideof the auxiliary medicine box are equipped with electromagnetic flow valves; one side of the electromagnetic flow valve is provided with a liquid medicine transport pipe; one end of the liquid medicine transport pipe is provided with a liquid medicine storage box; and a liquid medicine inlet pipe is mounted above the liquid medicine storage box. The UAV medicament spraying device for olive plantation has the advantages that: 1, the medicinal liquid can be stirred, and the artificial working time is saved, and the flow rate of the medicinal liquid can be controlled; and 2, the signal can be sent out in time when the liquid medicine is insufficient, and the user is reminded to withdraw the UAV.

Owner:四川益彰农业开发有限公司

Wood product die cutting marking press

InactiveCN107234679AWill not affect the quality of useEasy to useWood compressionProfiling/shaping machinesNumerical controlFixed frame

The invention discloses a wood product die cutting marking press. The wood product die cutting marking press comprises a work supporting rod, conveying equipment, a work machine case, a power device, a conveying belt and an impressing roller. A servo motor is arranged on one side of the upper end of the work supporting rod, and a control panel is arranged on the other side of the upper end of the work supporting rod. The conveying equipment is fixedly arranged on one side of the bottom end of the work supporting rod. A material bearing plate is arranged on one side of the upper end of the work machine case. The power device is arranged on one side of the bottom end in the work machine case. The conveying belt is fixedly arranged at the upper end of the center of the outer portion of the work machine case. Roller impressing equipment is fixedly arranged in the center of the lower end of the work supporting rod and fixed to the bottom end of the work supporting rod through a fixing frame at the upper end. Die cutting equipment is fixedly connected to one side of the bottom end of the work supporting rod. According to the wood product die cutting marking press, wood product impressing and die cutting are automatic, the impressing pressure and conveying speed can be adjusted in a numerical control manner, using is simple and convenient, and the work efficiency is improved.

Owner:鱼珠湾智能科技(广州)有限公司

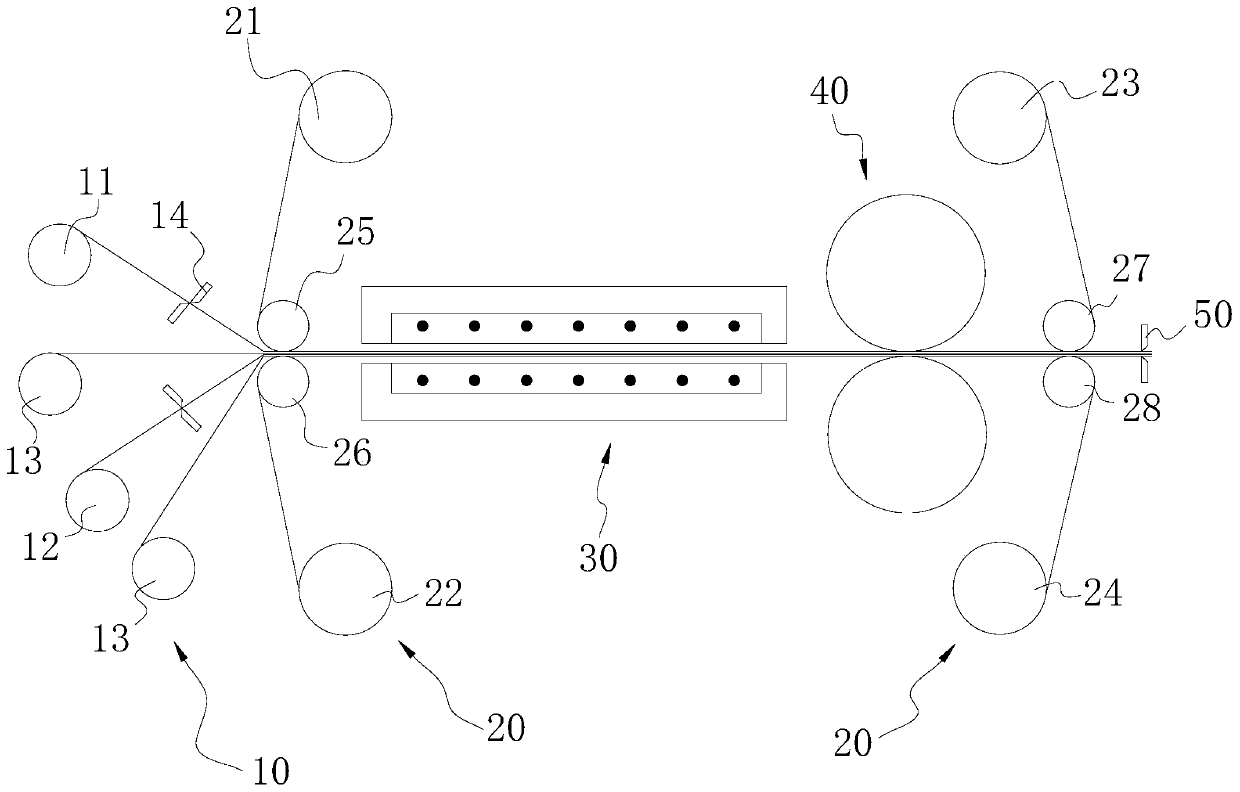

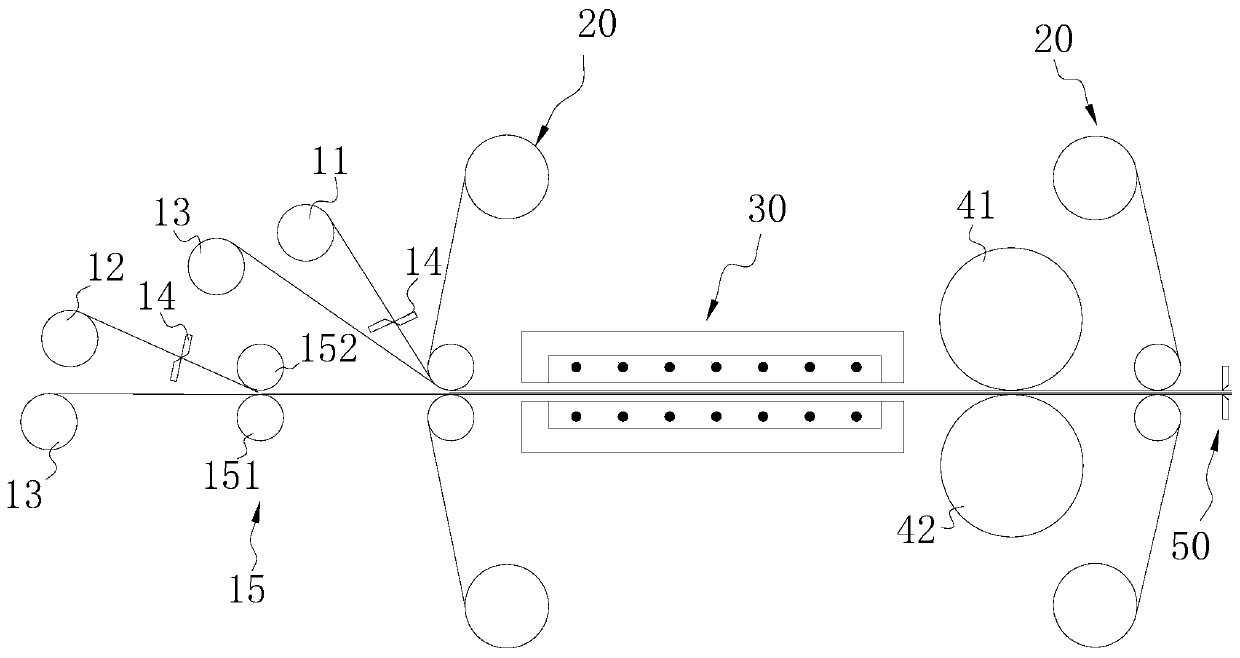

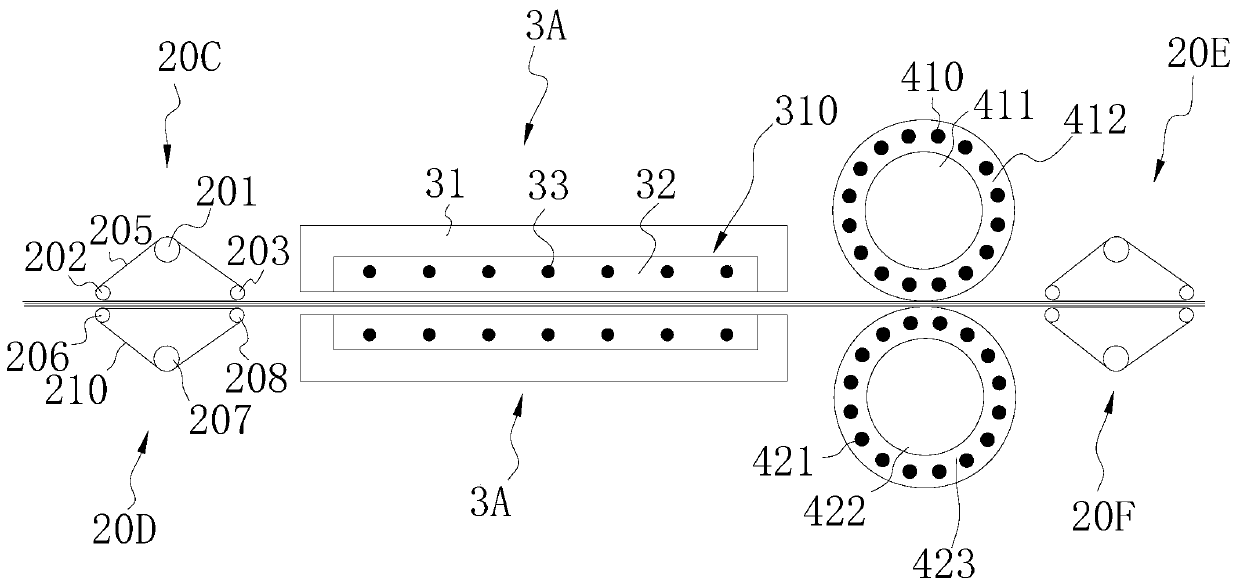

Lithium battery laminating machine

PendingCN110265730AReduce manual work timeIncrease productivityFinal product manufactureElectrolyte accumulators manufacturePole pieceHigh heat

The invention particularly relates to a lithium battery laminating machine, belonging to the technical field of lithium battery production equipment. The lithium battery laminating machine comprises a machine base, and further comprises a feeding device, a driving device, a heating device, a pressing device and a cutting device all arranged on the machine base, wherein the feeding device is used for inputting pole pieces and a diaphragm; the input end of the driving device is connected with the output end of the feeding device; the driving device is used for superposing the pole pieces and the diaphragm to allow the pole pieces and the diaphragm to form a composite body and for transporting the composite body; the heating device is used for heating the composite body to a predetermined high temperature; the pressing device is used for pressing the composite body so as to realize bonding and shaping of the high-temperature pole pieces and the high-temperature diaphragm; and the input end of the cutting device is connected with the output end of the driving device. The lithium battery laminating machine of the invention has the beneficial effects that the lithium battery laminating machine realizes automatic compounding of the pole pieces and the diaphragm, reduces manual operation and improves production efficiency.

Owner:东莞市联德企业管理有限公司

Automatic wire clamping and drawing device

The invention discloses an automatic wire clamping and drawing device. The automatic wire clamping and drawing device comprises a rack, and a wire clamping jig and a drawing device, which are arranged on the rack, wherein the drawing device comprises a guide rod and a driving unit, the driving unit is in transmission connection with the guide rod, the wire clamping jig comprises a support movably arranged on the guide rod and a wire clamping device arranged on the support, the wire clamping jig moves forwards and backwards along the guide rod under the action of the driving unit, and the wire is clamped and drawn by the wire clamping device. According to novel automatic auxiliary equipment provided by the invention, through the cooperation work of the wire clamping jig and the drawing device, a wire material can be automatically clamped and drawn to an appointed position during the injection molding of a power supply wire tail clip, then, automatic die assembly and injection molding are carried out, and the molding position of the tail clip can be accurately positioned. Compared with traditional manual locating, the automatic wire clamping and drawing device greatly increases the work efficiency and reduces manual operation time. By using the automatic wire clamping and drawing device, locating is more accurate, size errors are small, and the requirements of factories are met.

Owner:深圳市国信达科技股份有限公司

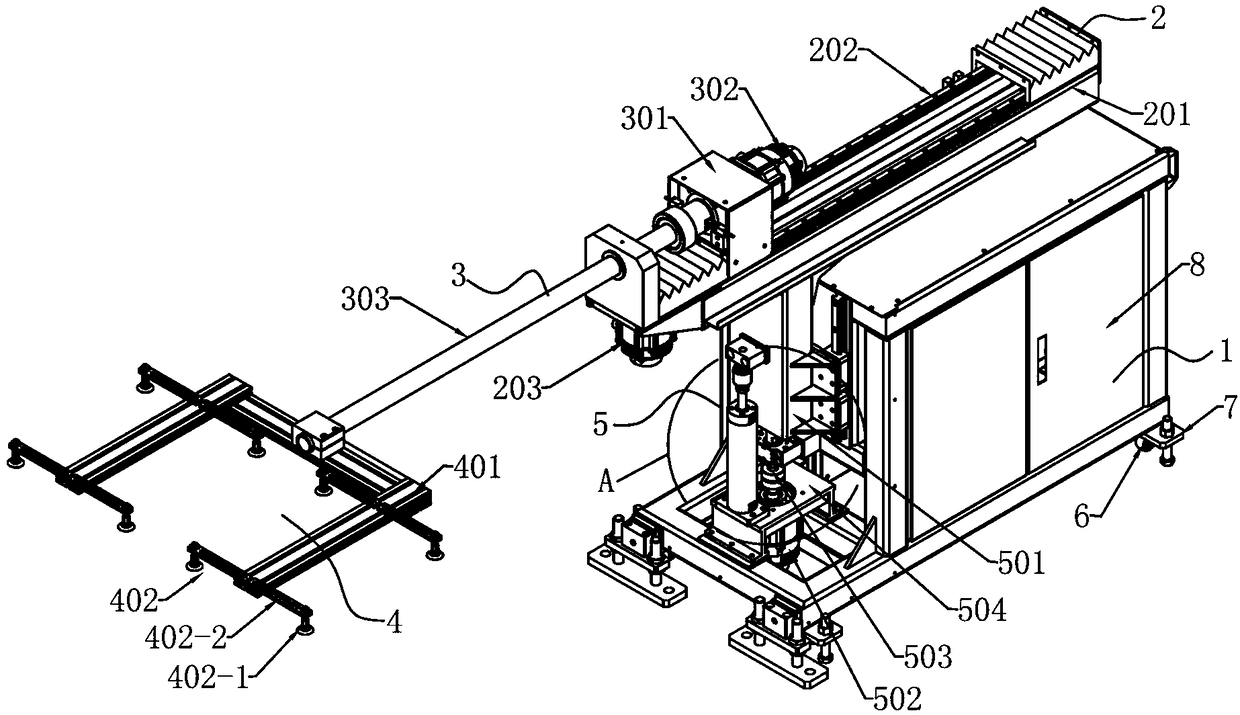

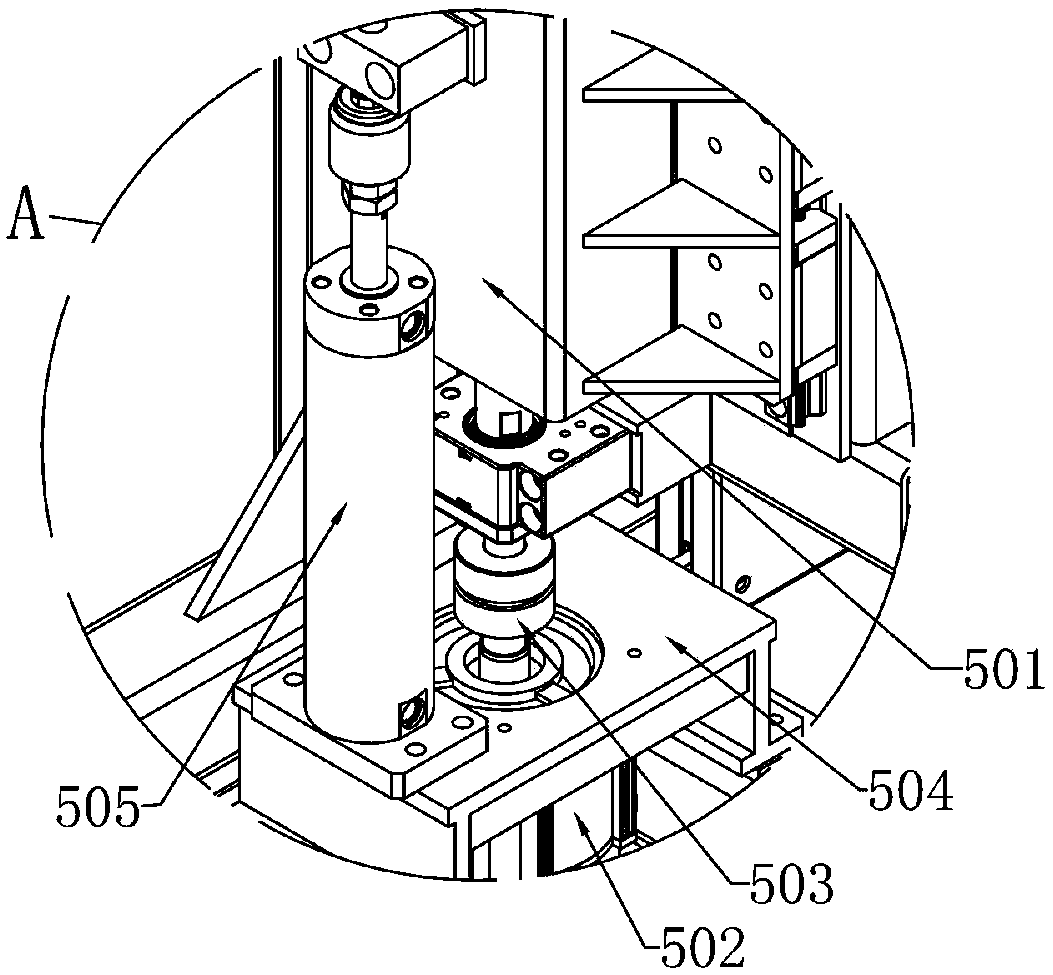

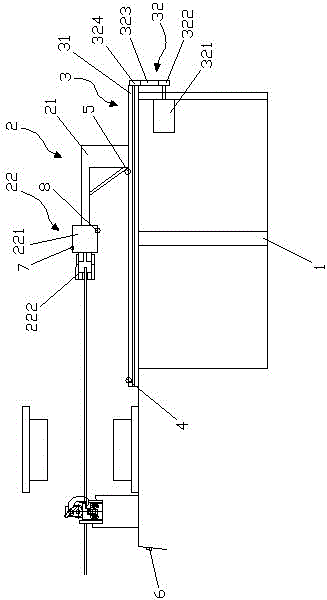

Visual measurement twisting system method and device for multifunctional aluminum electrolysis unit

PendingCN112981465AImprove the efficiency of anode replacement operationsReduce manual work timeProcess engineeringAluminum electrolysis

The invention discloses a visual measurement twisting system method and device for a multifunctionalaluminum electrolysis unit. The method comprises the steps: moving a visual lifting mechanism and a visual sensor disposed on the visual lifting mechanism to a position above an anode guide rod, carrying out the spatial positioning measurement of different positions, according to spatial position information fed back by the visual sensor, calculating a moving path of the twisting and pulling pole changing operation through a control device, correcting the position of each component, guiding a twisting and pulling lifting servo hydraulic cylinder to drive the corresponding component to move, conveying an anode needing to be replaced to a stacking place to be put down after completing preset actions, and then grabbing a new anode to return to the original position until the new anode is fixed on an electrolytic bath. According to the visual measurement twisting system method and device for a multifunctional aluminum electrolysis unit, automatic positioning is achieved through vision measurement, the whole aluminum electrolysis production anode replacement twisting operation is completed, the anode replacement operation efficiency can be improved, the manual operation time is shortened, the labor intensity is relieved, and the production operation safety is improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

A high-efficiency electroplating pollution reduction device

ActiveCN108455715BImprove processing efficiencySave mixing processing timeShaking/oscillating/vibrating mixersTransportation and packagingDrive wheelDrive shaft

The invention discloses a high-efficiency electroplating pollution emission reduction device, which comprises a main box body. There is a support rod, and the top of the support rod is fixed with a drive seat body, and a transmission chamber is extended left and right in the drive seat body, and the center of the transmission chamber is rotated to cooperate with a device extending up and down and extending into the water storage chamber. The transmission shaft, the top extension end of the transmission shaft protrudes from the top end surface of the drive seat body and a drive motor is installed in power cooperation, the drive motor is fixed on the top end surface of the drive seat body, and all the transmission chambers The outer surface of the transmission shaft is fixed with a double-groove transmission wheel in the circumferential direction, and the right side of the bottom wall of the transmission chamber is rotated and fitted with a first spline shaft protruding from the bottom end surface of the drive seat body. The first spline The top end of the shaft is fixed with a first transmission wheel.

Owner:江门市精创表面处理有限公司

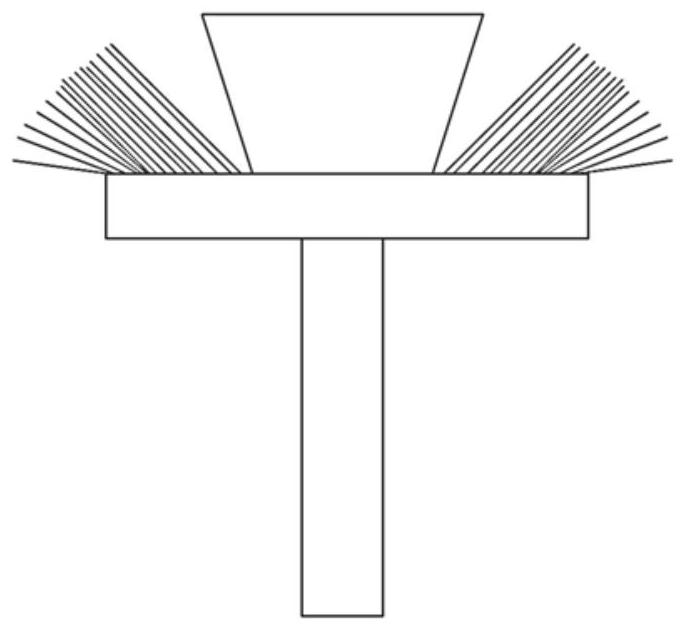

A polishing process for the channel opening of the back plate in a molybdenum-niobium target assembly

The invention relates to a polishing process for the water channel opening of the back plate in the molybdenum-niobium target assembly, the polishing process includes polishing the water channel opening of the back plate in the molybdenum-niobium target assembly; the polishing is carried out by using an umbrella-shaped polishing brush Polishing; the rotation direction of the polishing brush in the polishing is clockwise; the umbrella-shaped polishing brush includes a rounded truncated polishing surface and a band-shaped polishing surface distributed around it; the angle between the rounded truncated side and the horizontal plane It is 85-88 °, and the diameter of the bottom surface of the rounded frustum-shaped polishing surface is 1.5-3cm; the width of the strip-shaped polishing surface is 0.2-0.5mm; the polishing wires are radially distributed in the strip-shaped polishing surface, and the distribution range is 0 ‑45°, relative to the horizontal plane. The invention makes the polishing stable through the specific selection of the polishing process and the polishing medium, and prolongs the service life of the water channel mouth after polishing.

Owner:合肥江丰电子材料有限公司

A method of improving the surface finish of wooden mould

The invention relates to the field of wood mold casting, in particular to a method for improving the plane smooth degree of a wood mold. The method comprises the following steps that 1, the mold is designed, wherein software is used for designing a wood mold structure, the size of all plane portions of the wood mold is reduced by 1 mm, and all the plane portions are used for installing aluminum plates; 2, the mold is manufactured, wherein according to the wood mold structure, wood is used for machining and manufacturing the mold; 3, the aluminum plates are bonded, wherein a plate shearing machine is used for shearing the aluminum plates, and the aluminum plates are bonded to all the planes of the wood mold; 4, the edges of the aluminum plates are reinforced, wherein the edge portions of the aluminum plates are reinforced by riveting rivets, and cracking is prevented; and 5 the surface of the mold is treated, wherein the connecting portions of the aluminum plates and other faces are sanded and polished. By installing the aluminum plates on all the surfaces of the wood mold, the wood mold plane smooth degree is improved, the situation that due to the fact that sand adheres to the wood mold, the wood mold is damaged is prevented, drawing performance of the wood mold can be reinforced, the surface quality of sand cores is improved, few mold releasing agents are used, manual operation time can be shortened, and the working efficiency is improved.

Owner:KOCEL EQUIP

Combined rotating paddle no-seal paper pulp stirring equipment assembly and use method thereof

InactiveCN106799180AReduce processing timeSimple and safe operationRotary stirring mixersTransportation and packagingCouplingMechanical equipment

The invention relates to the technical field of papermaking mechanical equipment, in particular to combined rotating paddle no-seal paper pulp stirring equipment assembly and a use method thereof. The equipment comprises a base part, a paper pulp stirring pool, a combined rotating mechanism and an electric motor. The equipment assembly comprises the following steps that the electric motor and an active rotating shaft are installed; a combined rotating mechanism and accessories of the combined rotating mechanism are installed; the combined rotating mechanism, the paper pulp stirring pool and the base part are partially assembled; an output shaft of the electric motor drives the active rotating shaft to rotate through a rigid shaft coupler; the active rotating shaft respectively transfers torque to a revolution active belt wheel and an autoroatation active belt wheel through a main shaft revolution key and a main shaft autoroatation key; the combined rotating mechanism integrally does rotating movement around an axial line formed between a driven lower bearing seat and a pulp pool positioning hole; under the combined force effect of autoroatation movement and revolution movement, a stirring paddle performs uniform stirring and mixing treatment on paper pulp above a pulp pool bottom plate; no stirring dead corners are left; the stirring efficiency is improved; the work energy consumption is reduced.

Owner:温州立意机电科技有限公司

Hierarchical sequence analysis method oriented to generation of three-dimensional hierarchical grids

ActiveCN102176052BImprove processing efficiencyReduce manual work timeSeismic signal processingSequence analysisStructure analysis

The invention discloses a hierarchical sequence analysis method oriented to the generation of three-dimensional hierarchical grids, which is used for geologic stratum modeling and underground structure analysis, and is characterized by comprising the following steps of: scanning surface patches consisting of discrete points; establishing a target function according to the scanned result; solving the solution of the target function in case of a minimum value, and considering the solution as a sequence value of the surface patches; and classifying the surface patches by using the sequence value, and considering classified surface patches as data of the generation of the hierarchical grids. When the method disclosed by the invention is adopted, the automatic classification of automatic tracking results of axes in the same direction can be realized, and therefore, automatic explanation can be completed, and heavy manual classification and pickup can be eliminated; moreover, efficiency of the explanation process from a seismic data body to a hierarchical grid modeling is effectively improved.

Owner:北京网格天地软件技术股份有限公司

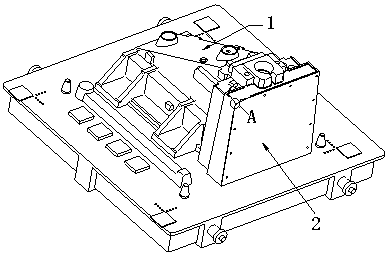

Automatic assembling and detecting equipment for adjustable spanner

PendingCN113695883ASolve the problem of poor markingRealize automatic eliminationUsing optical meansMetal working apparatusEngineeringIdler-wheel

The invention relates to automatic assembling and detecting equipment for an adjustable spanner. The automatic assembling and detecting equipment is characterized by comprising a pin shaft mounting mechanism for preassembling a pin shaft, a sealing mechanism for packaging the pin shaft, a detecting mechanism for implementing quality detection, a laser marking mechanism for marking, an oiling mechanism for oiling a product and a carrying mechanism for carrying the product. According to the automatic assembling and detecting equipment, automatic feeding, automatic loading of the pin shaft into the spanner, automatic sealing, automatic detection and automatic marking are achieved through a vibration disc, automatic grabbing and automatic carrying of the spanner and automatic rejecting of unqualified products are achieved, and the manual operation time is effectively shortened; and an idler wheel controlled by a servo motor rotates to drive a spanner worm wheel to rotate, and automatic detection is achieved in cooperation with a sensor and a camera. The problem of poor wrench marking caused by unstable manual detection is solved.

Owner:烟台三环智能装备有限公司

Seedling planting device having automatic feeding function

InactiveCN108575207AReduce manual work timeImprove work efficiencyPlantingDibble seedersEngineeringConveyor belt

The invention relates to a seedling planting device having an automatic feeding function. A base is arranged at the bottom of a support frame; a conveyor belt is arranged on the base; guiderail grooves are formed in the two sides of the support frame; a support slide block is arranged in the guiderail groove in a sliding way; a digging and planting mechanism capable of sliding up and down is arranged between the two support slide blocks, a support column is arranged on one side of the support slide block, the support column is fixed on the support frame, the two support columns are connected through a fixing column, a plurality of first telescopic rods are arranged at the lower part of the fixing column; the bottom of the first telescopic rod is connected with an extruding block; corresponding grooves are arranged in the inner sides of the two support frames; a culture groove is placed in the groove; a feeding mechanism and a suction mechanism are respectively arranged on the two sidesof the support frame. Through the digging and planting mechanism, the automatic feeding, the digging and the planting are implemented, the manual work hour is greatly shortened, the working efficiency is improved, and the device has a certain practical value.

Owner:苏州寿丰农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com