Automatic assembling and detecting equipment for adjustable spanner

A technology for automatic assembly and testing equipment, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high labor intensity for operators, high manufacturing cost, hindering the development of enterprises, etc., and achieve the goal of shortening manual work time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

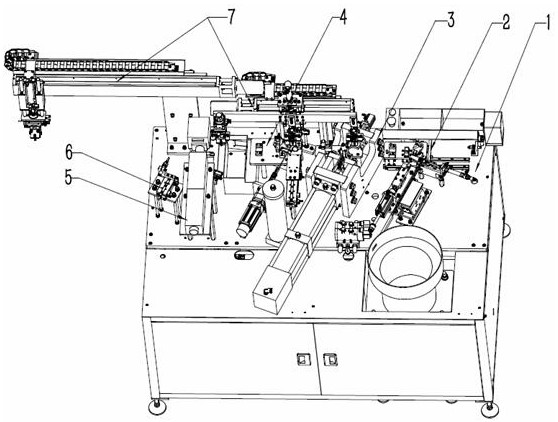

[0022] A kind of adjustable wrench automatic assembly detection equipment, such as figure 1 As shown, its main structural composition includes a pin installation mechanism 2 installed on the frame 1, a sealing mechanism 3, a detection mechanism 4, a laser marking mechanism 5, an oiling mechanism 6 and a handling mechanism 7; among them,

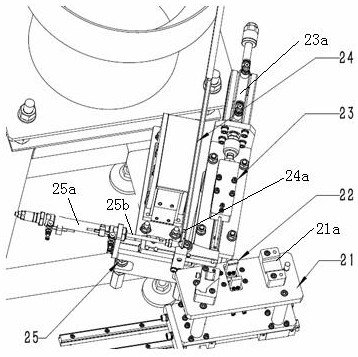

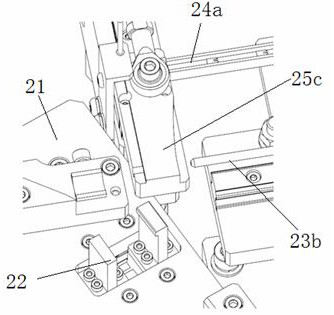

[0023] The pin shaft installation mechanism 2 is used to complete the assembly of the pin shaft on the adjustable wrench, and its structure includes: a positioning tool 21, a pneumatic gripper 22, a lifting component 23, a vibrating plate 24 and a material cutting component 25; the positioning tooling 21 is used to install the adjustable wrench, so its surface is provided with a profiling block 21a matching the shape and contour of the adjustable wrench, and the pneumatic gripper 22 is used to clamp the middle part of the adjustable wrench and perform clamping and positioning thereof. The pin shafts are vibrated and fed through the vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com